Evaluation device and evaluation method for scale formation trend and scale inhibition effect

An evaluation device and evaluation method technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of complex structure, high cost, and large sample volume of experimental devices, and achieve the effect of wide application range and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

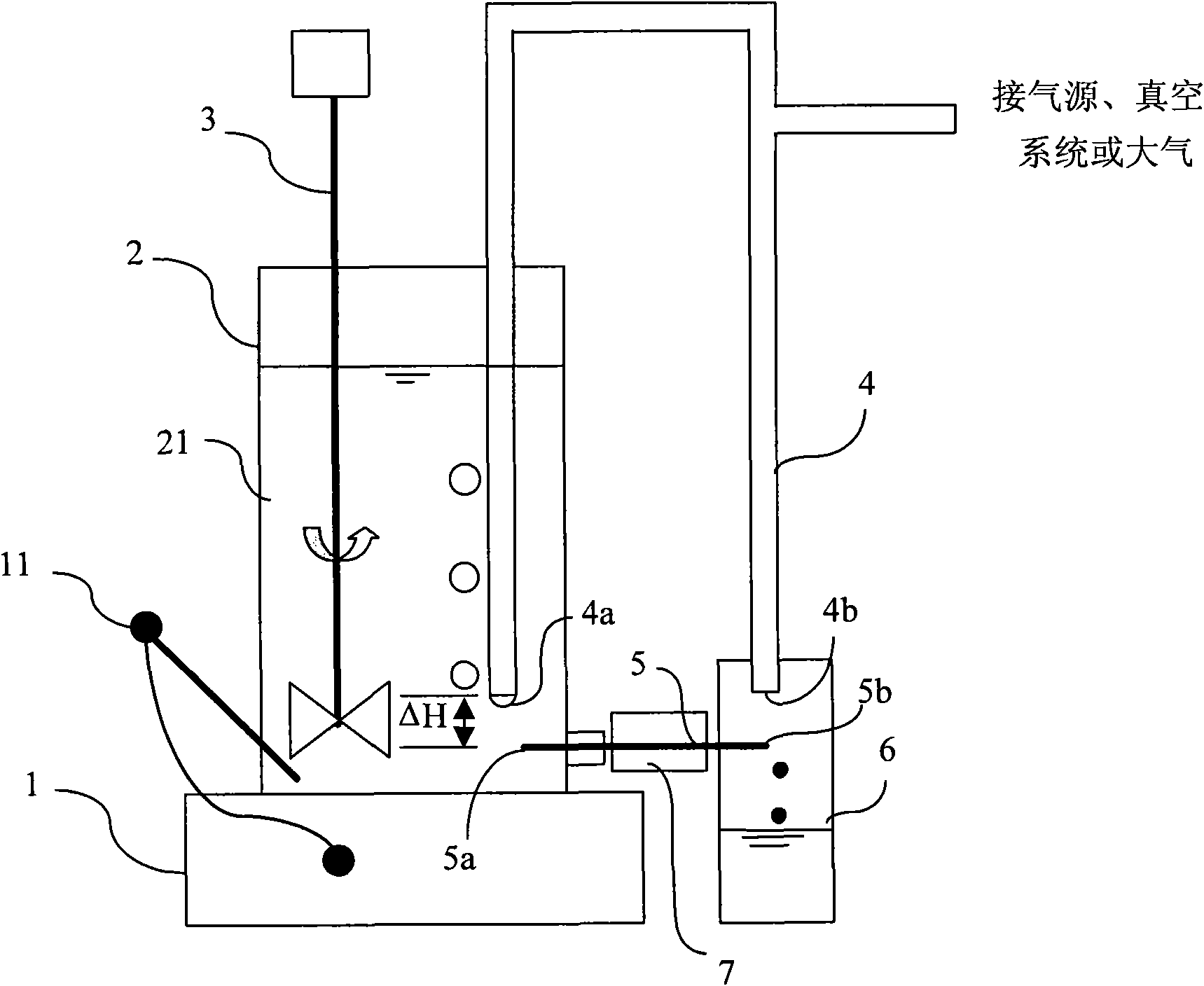

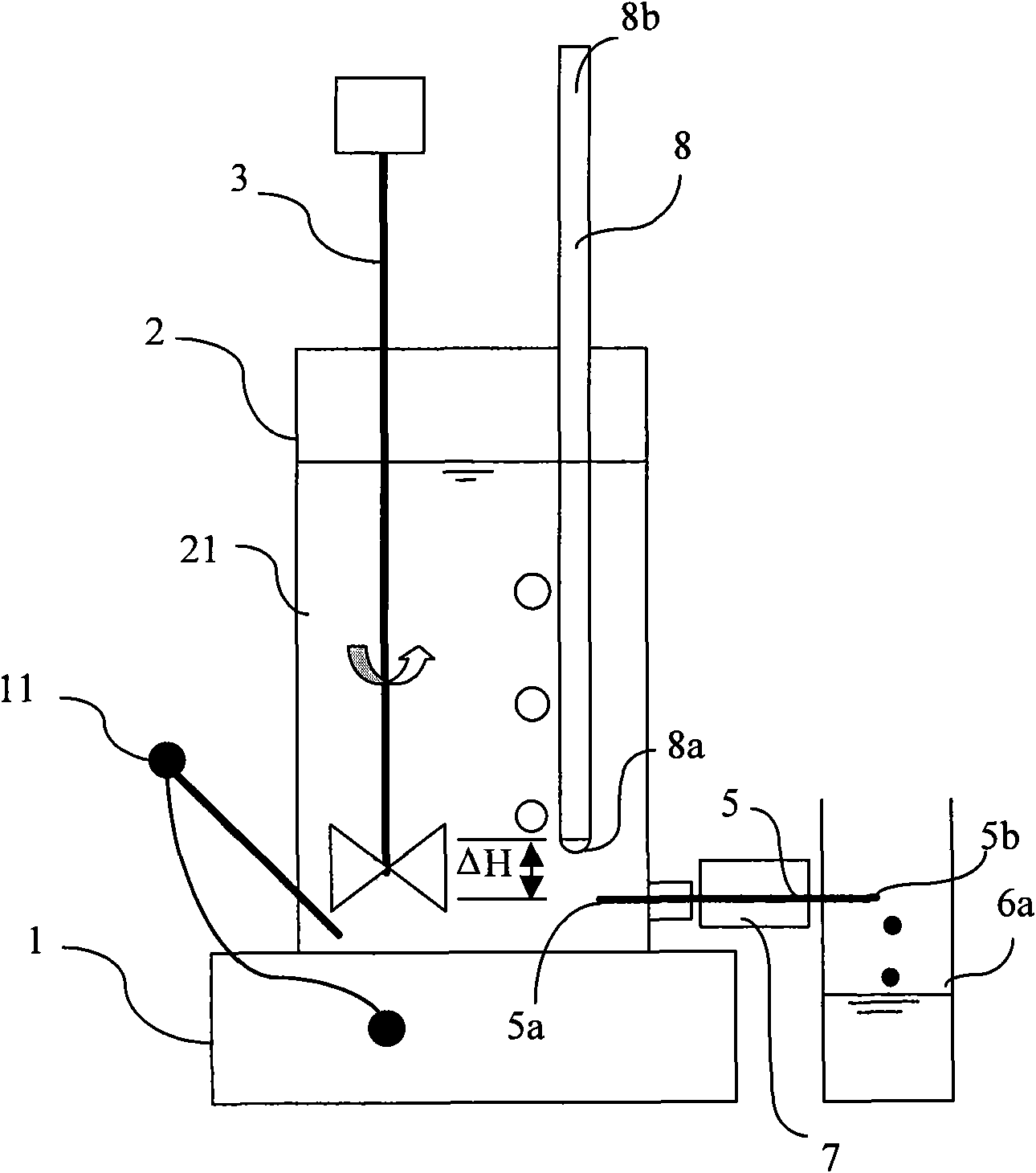

Method used

Image

Examples

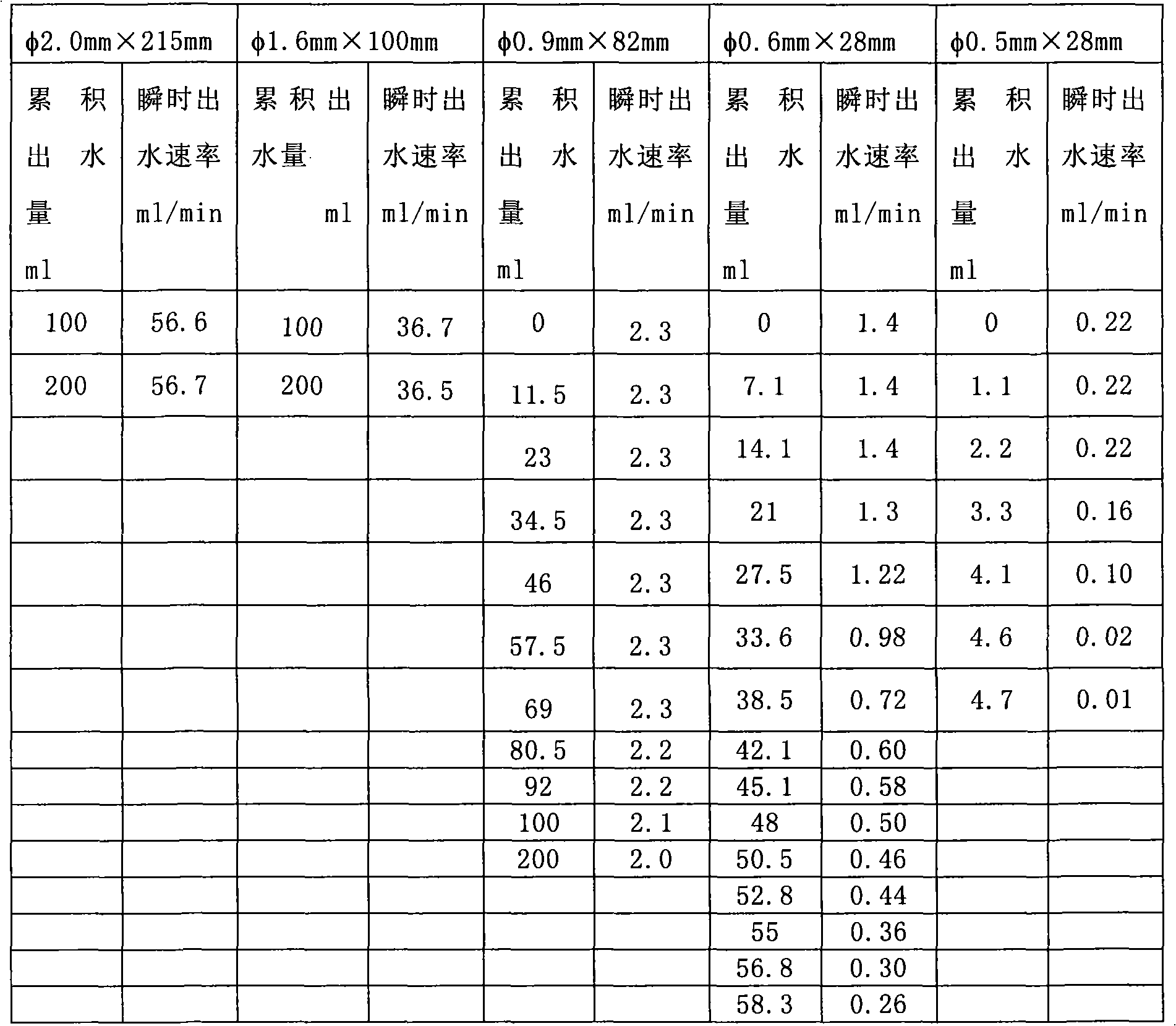

Embodiment 1

[0060] Latex tubes are installed on the outlet valve of the glass bottle with a capacity of 2500ml, and 5 tubes are inserted into the latex tubes at the same time. × 28mm, φ0.5mm × 28mm stainless steel capillary; place the glass bottom bottle on a magnetic stirrer in an air bath at a temperature of 25°C, add a magnetic stirrer with a size of φ8mm × 50mm in it, and put it in each stainless steel capillary Place a glass measuring cylinder under each end; preheat deionized water, 1% sodium carbonate aqueous solution and 1% calcium chloride aqueous solution in a water bath with a water temperature of 25°C for 30 minutes; Add 25ml of sodium carbonate aqueous solution with a mass concentration of 1%, 2425ml of deionized water and 50ml of a calcium chloride aqueous solution with a mass concentration of 1% in the bottle, start the magnetic stirrer and start stirring at a speed of 300r / min; Cover the 16# rubber stopper of ×400mm glass tube on the lower glass bottle; turn on the switch ...

Embodiment 2

[0066] Install a latex tube on the outlet valve of the glass bottom bottle with a capacity of 2500ml, and insert a stainless steel capillary tube with a size of φ0.6mm×28mm on the latex tube; place the glass bottom bottle at a temperature of 25°C in an air bath On the magnetic stirrer, a magnetic stirrer with a size of φ8mm×50mm is added therein, and a glass measuring cylinder is placed under the end of the stainless steel capillary; deionized water, a 1% sodium carbonate aqueous solution and a mass concentration of 1% chlorine The calcium chloride aqueous solution is placed in a water bath with a water temperature of 25° C. for preheating for 30 minutes; 25 ml of a mass concentration of 1% sodium carbonate solution and 1.25 ml of a mass concentration of 1% aminotrimethylene phosphoric acid (ATMP) are successively added to the lower glass bottle. Aqueous solution, 2424ml of deionized water and 50ml of calcium chloride aqueous solution with a mass concentration of 1%, start the ...

Embodiment 3

[0073] Heat 2500ml of a kind of dehydrated and degassed crude oil in a water bath at 80°C for 48 hours (hours) and then place it in a water bath at 60°C for 12 hours; install a silicone tube on the outlet valve of a glass bottle with a capacity of 2500ml, Insert a stainless steel capillary tube with a size of φ2.0mm×215mm on the silicone tube; place the glass bottom bottle on a magnetic stirrer with a heating function in an air bath at a temperature of 36°C, and add a capillary tube with a size of φ8mm×50mm to it. With a magnetic stirring bar, pass the end of the stainless steel capillary through the upper part of a plastic measuring cylinder with a capacity of 10ml, and cover the plastic measuring cylinder with a rubber plug inserted with a φ7mm glass tube; pour the oil sample into a glass bottom bottle, and start the magnetic stirrer Start to stir at a speed of 300r / min; put a 16# rubber stopper inserted with a φ7mm×400mm glass tube and a magnetic stirrer temperature probe on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com