Water-oxygen fractionating purification vacuum glove box

A vacuum glove box and grading separation technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of increasing the amount of water and oxygen adsorbents, increasing the cost, and inability to adsorb and purify, and shorten the purification time. time, extend service life, improve efficiency and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

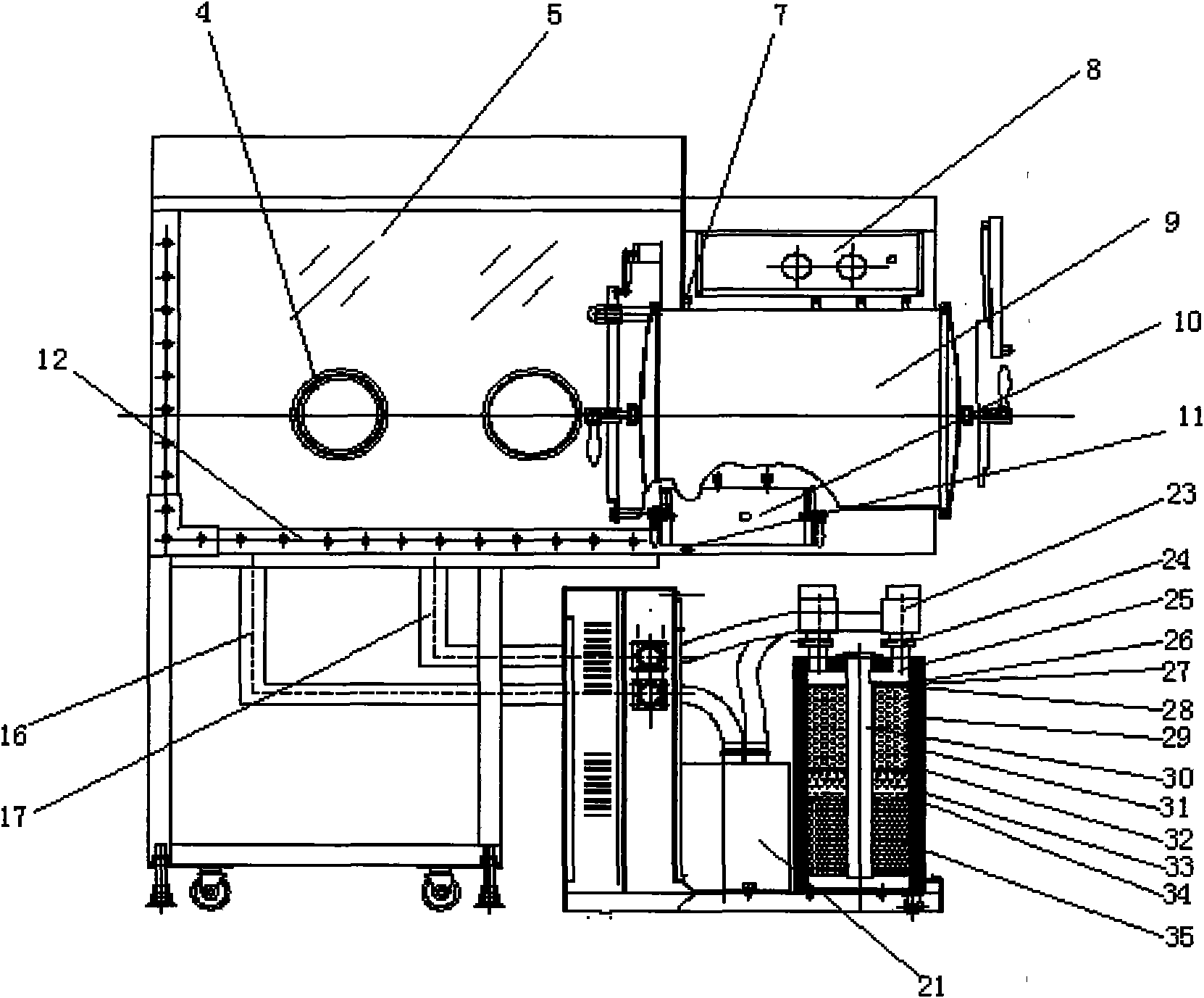

[0011] figure 1 Among them, the intake pipe 17 and the exhaust pipe 16 connect the casing 12 with the purification system. The glove assembly 4 is airtightly connected with the glass 5, and the glass 5 is airtightly connected with the box body; a sealing ring 7 and a sealing ring 11 are respectively arranged between the transition chamber 9, the tool bay 10 and the box body 12 to realize the airtight connection. The transition cabin 9 is used for transferring items, and the tool cabin 10 provides tool storage for operations in the box body 12 . The glove assembly 4 is provided with gloves for operation in the box.

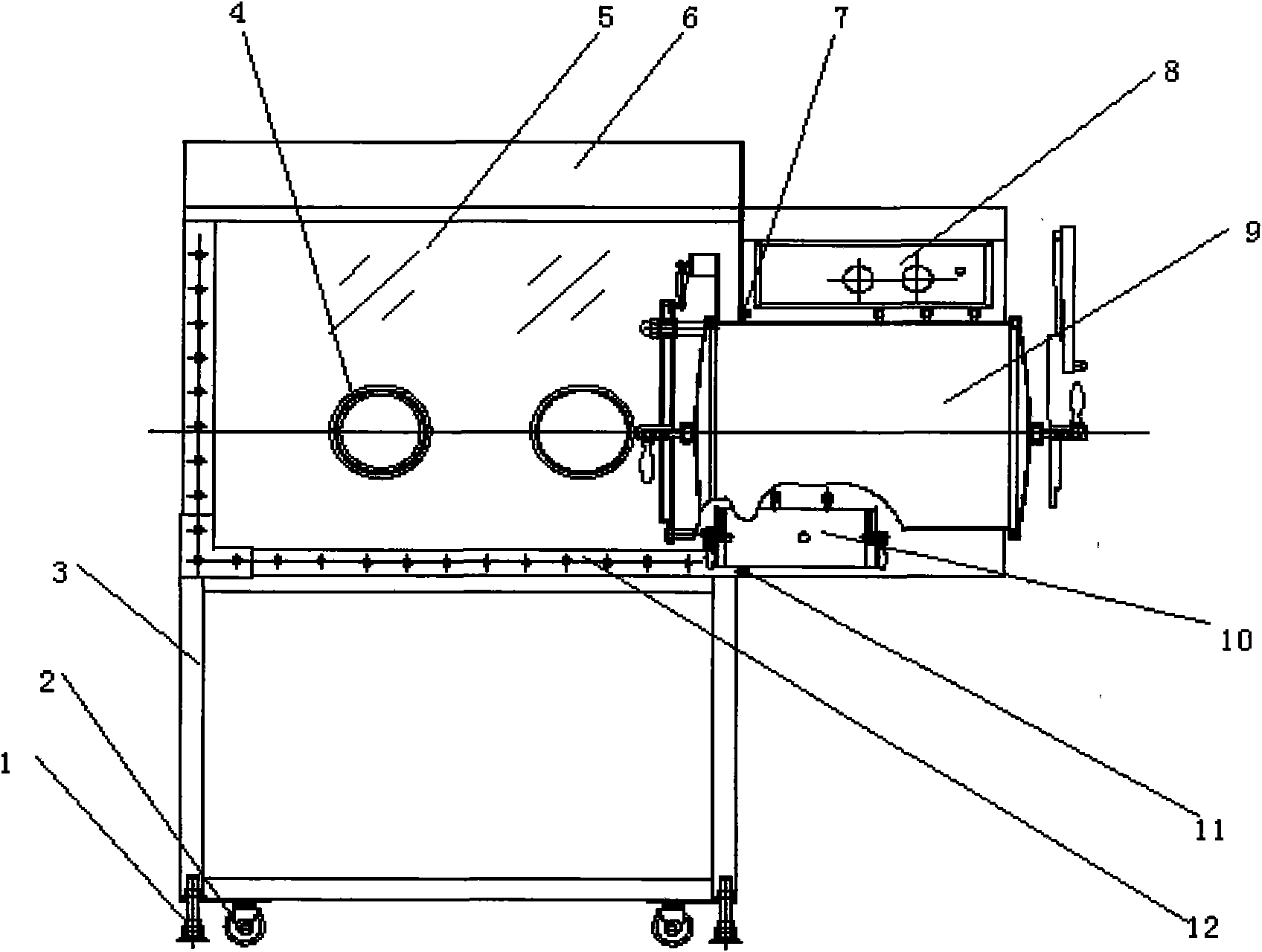

[0012] figure 2 Among them, the bracket 3 supports the casing 12 to a height suitable for human operation, the height of which can be adjusted by the adjusting foot 1, and the roller 2 is fixed under the bracket 3 with screws, so as to be convenient to move. The lighting device 6 is used for lighting, and the control panel 8 is equipped with control electrical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com