Medical manual automatic control secondary filter valve

A precision filter and valve technology, applied in the field of medical equipment, can solve the problems of 6:100 inner conical joint connection, valve without precision filter function, etc., and achieve the effect of preventing infusion reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

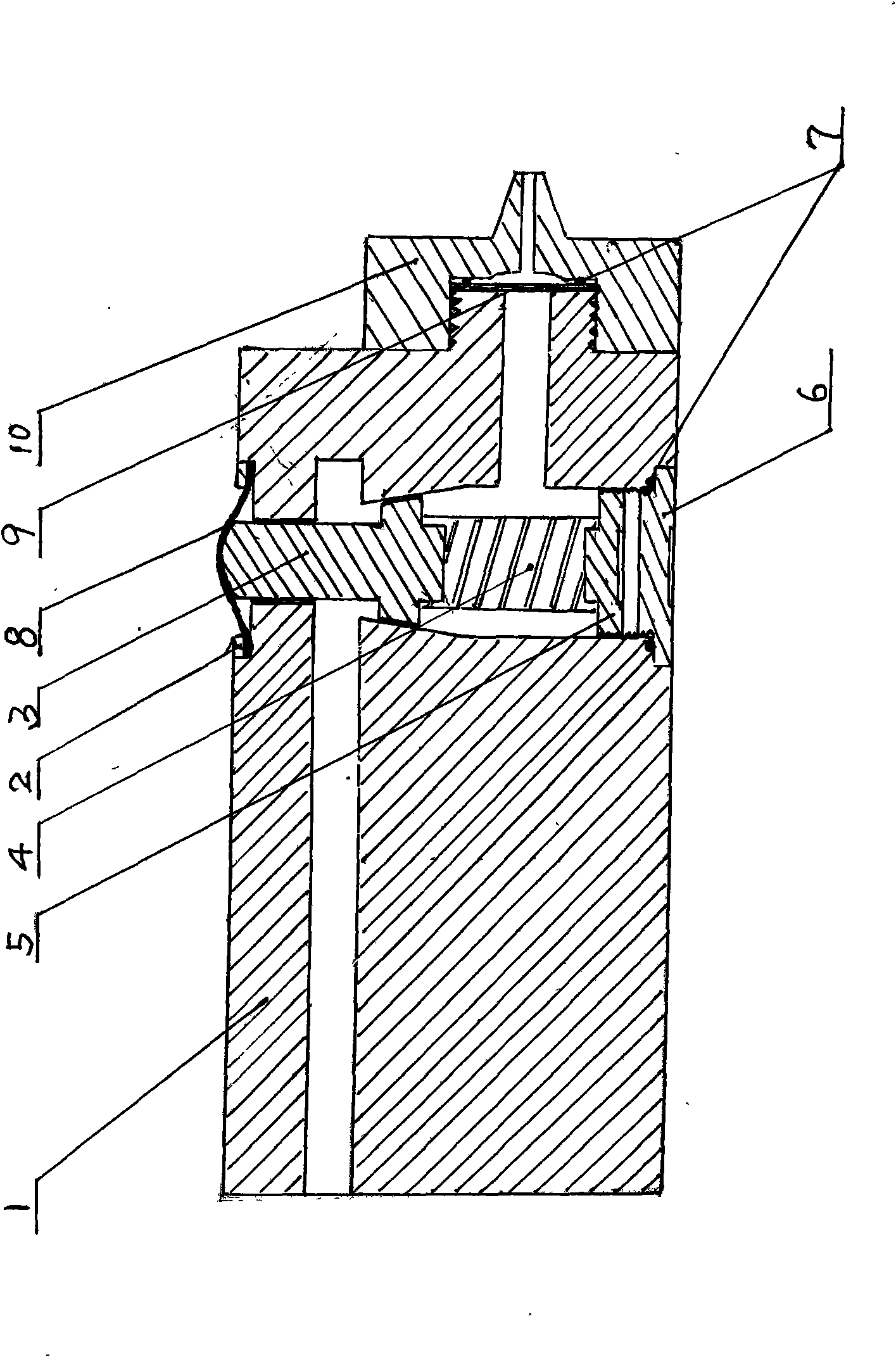

[0009] Further illustrate the present invention below in conjunction with accompanying drawing: valve body (1), fixed ring (2), adjusting screw (5), bolt (6), valve mouth (9) are made with medical stainless steel material, and spool (3) is used Polymer material is made, rubber ring (7), rubber pad (8) are made of rubber, and filter membrane (9) is made of fiber material. Valve body (1), retaining ring (2), valve core (3), spring (4), adjustment screw (5), bolt (6), rubber ring (7), rubber pad (8), filter membrane (9 ), the valve mouth (10) constitutes a medical manual automatic control precision filter valve. It is characterized in that the valve body (1) has an inlet and outlet and a valve core (3) installation port; the fixing ring (2) has a hole, and is fixed with the valve body (1) by screws; the upper and lower ends of the valve core (3) are cylinders , the cylinder at the upper end protrudes from the valve body (1), and is sealed with a rubber pad (8) and a fixed ring (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com