Bowl and dish brushing method

A technology for dishes and dishwashing brushes, which is applied to the washing machine/washing machine, cleaning equipment, household utensils, etc. The effect of fast, high efficiency and simple equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and some examples.

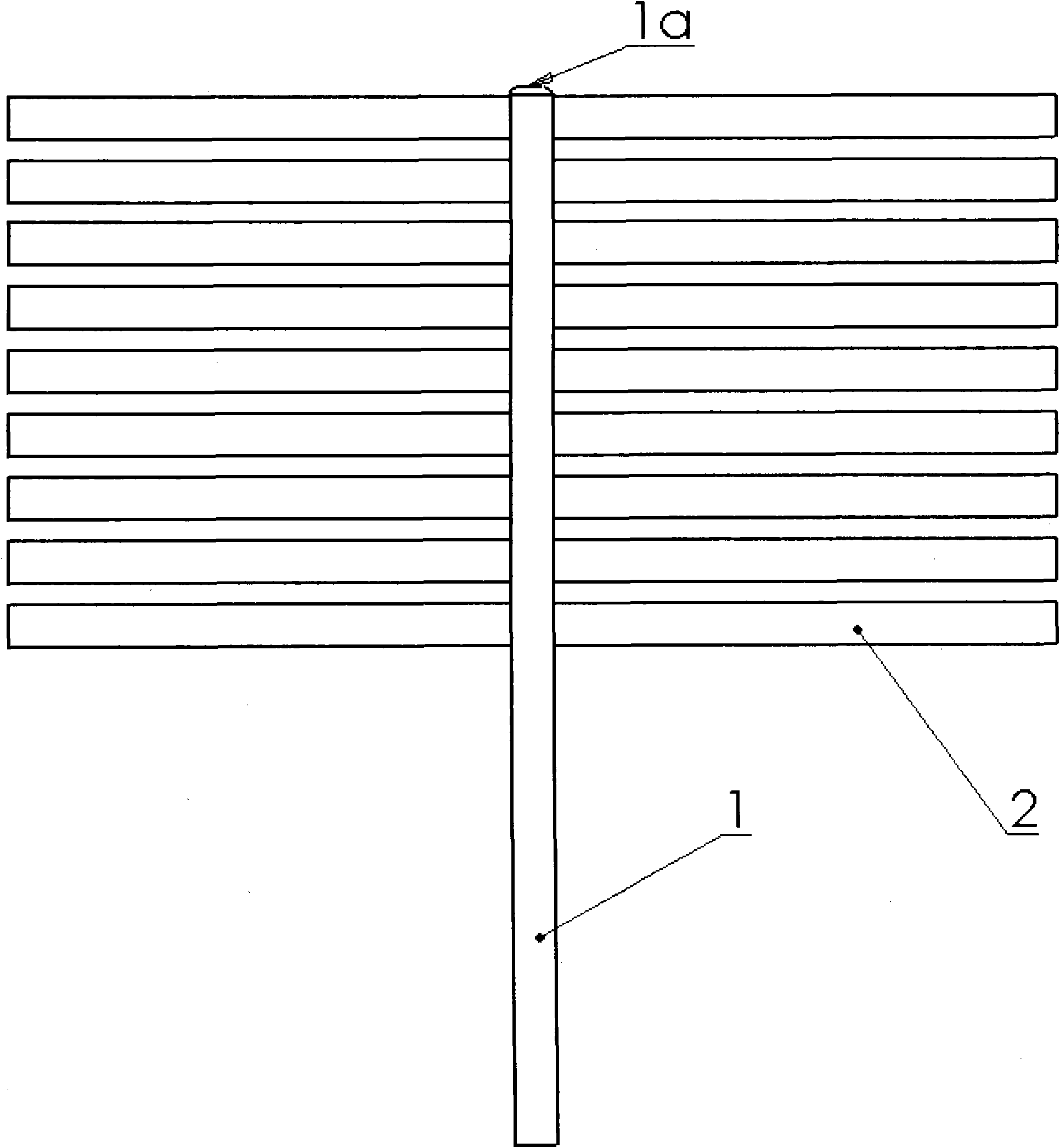

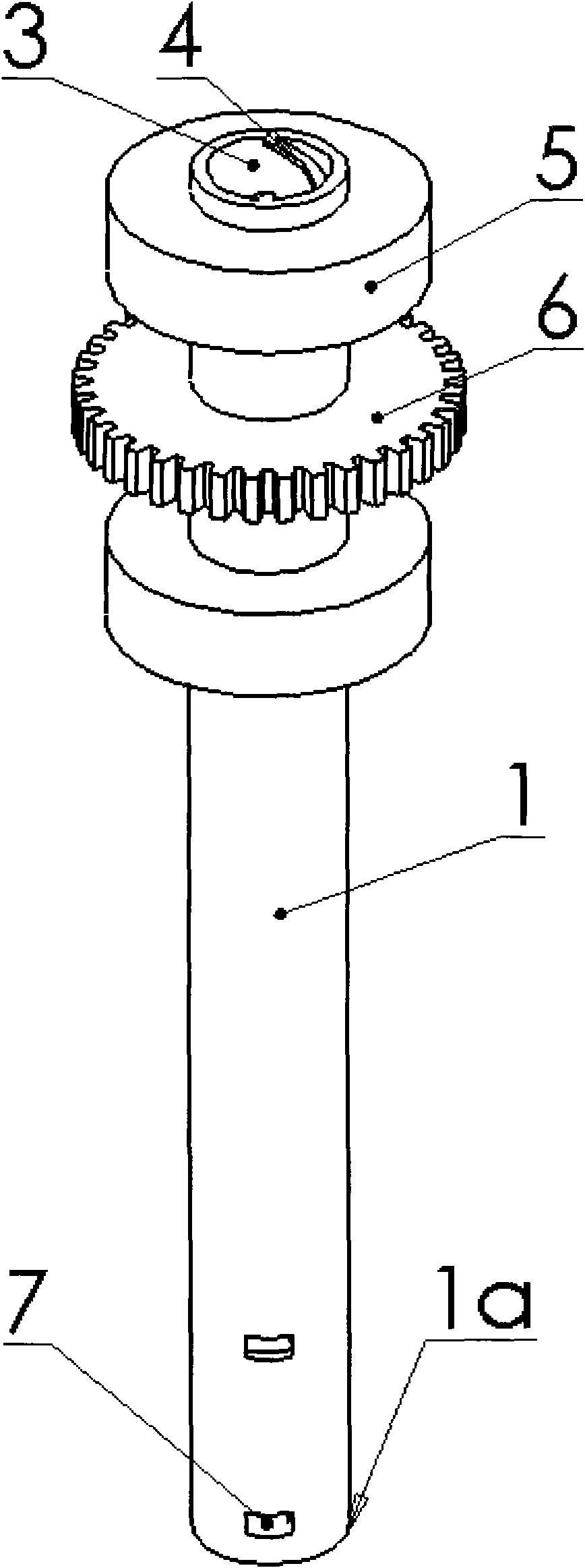

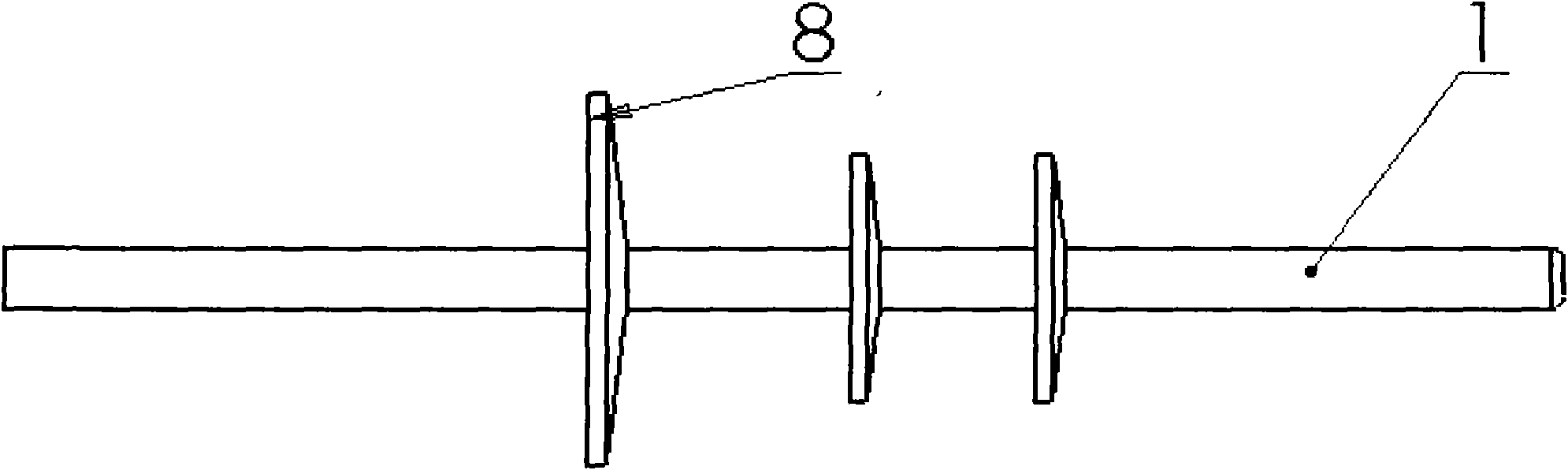

[0059] Such as figure 1 Shown is a schematic diagram of the dishwashing brush of the present invention, said dishwashing brush is made up of a dishwashing shaft 1 and a dishwashing bar 2, wherein 1a is the front end of the dishwashing shaft. The dishwashing shaft 1 can obtain rotational power from a power source such as a motor, and its power transmission-related components are not shown in the figure. Generally speaking, the transmission components are pulleys, gears, etc., and components such as bearings are used to fix the dishwashing shaft 1. shaft, and these components are usually installed at the rear of the dishwashing shaft; one end of several dishwashing bars 2 is connected to the front of the dishwashing shaft 1, and the other end is free to hang. The key is that the dishwashing bars 2 are made of soft Strips made of flex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com