Transition temperature method for detecting aggregative state of asphalt with ultraviolet aging

A technology of transformation temperature and aggregation state, used in thermometers, thermometers, measuring devices, etc. with physical/chemical changes, it can solve the problems of high cost, complicated detection methods, and complicated operation of expansion measurement methods, and achieve the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

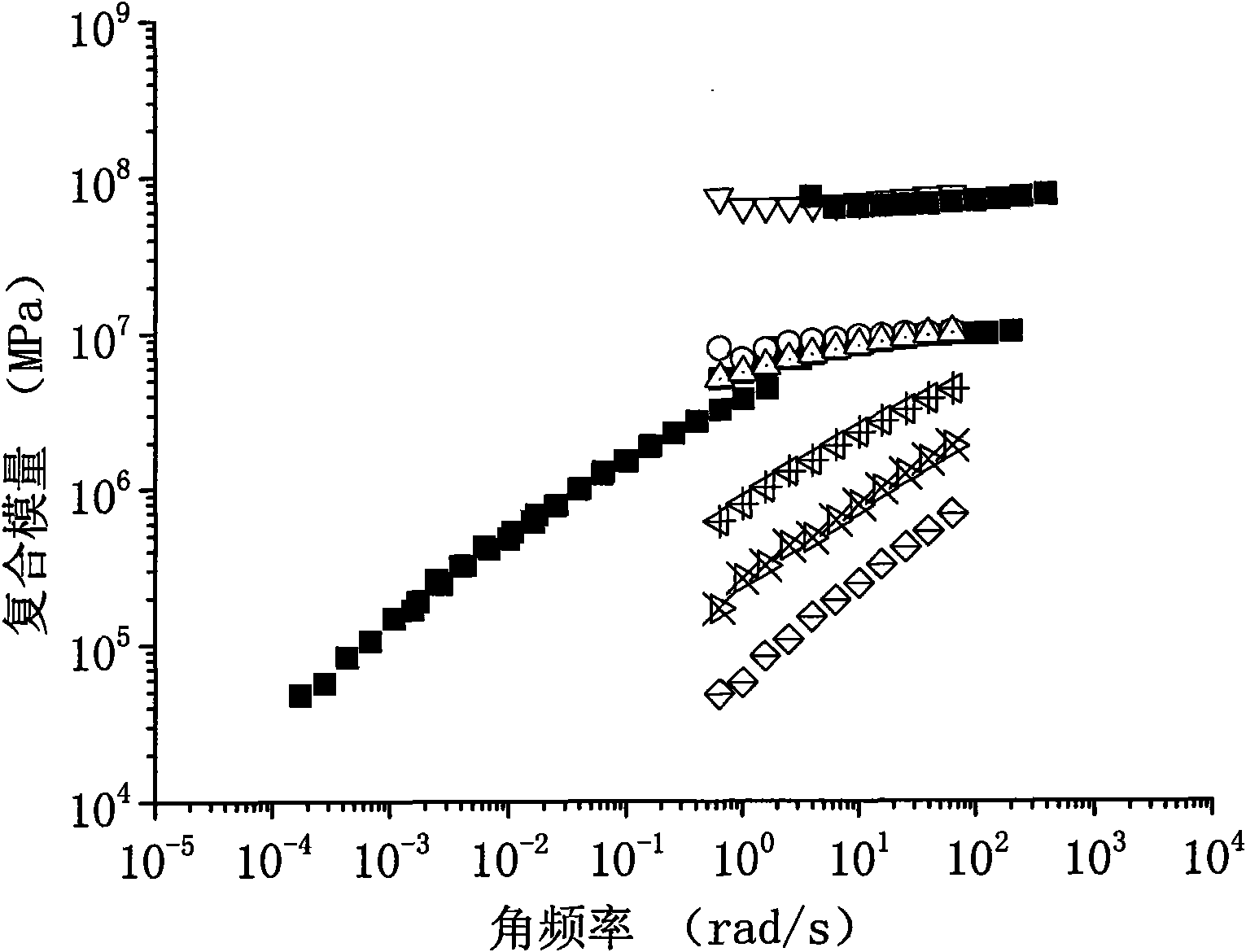

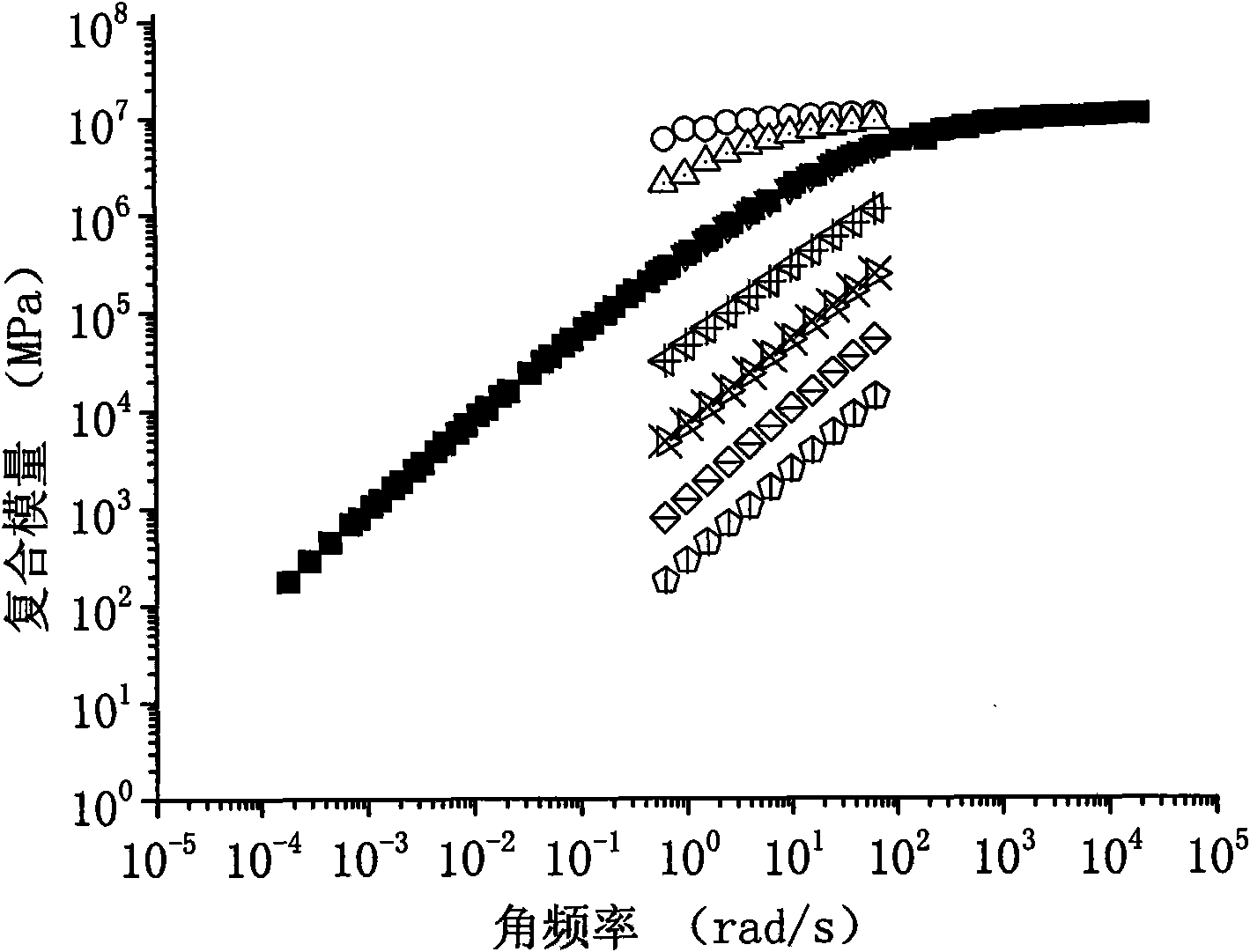

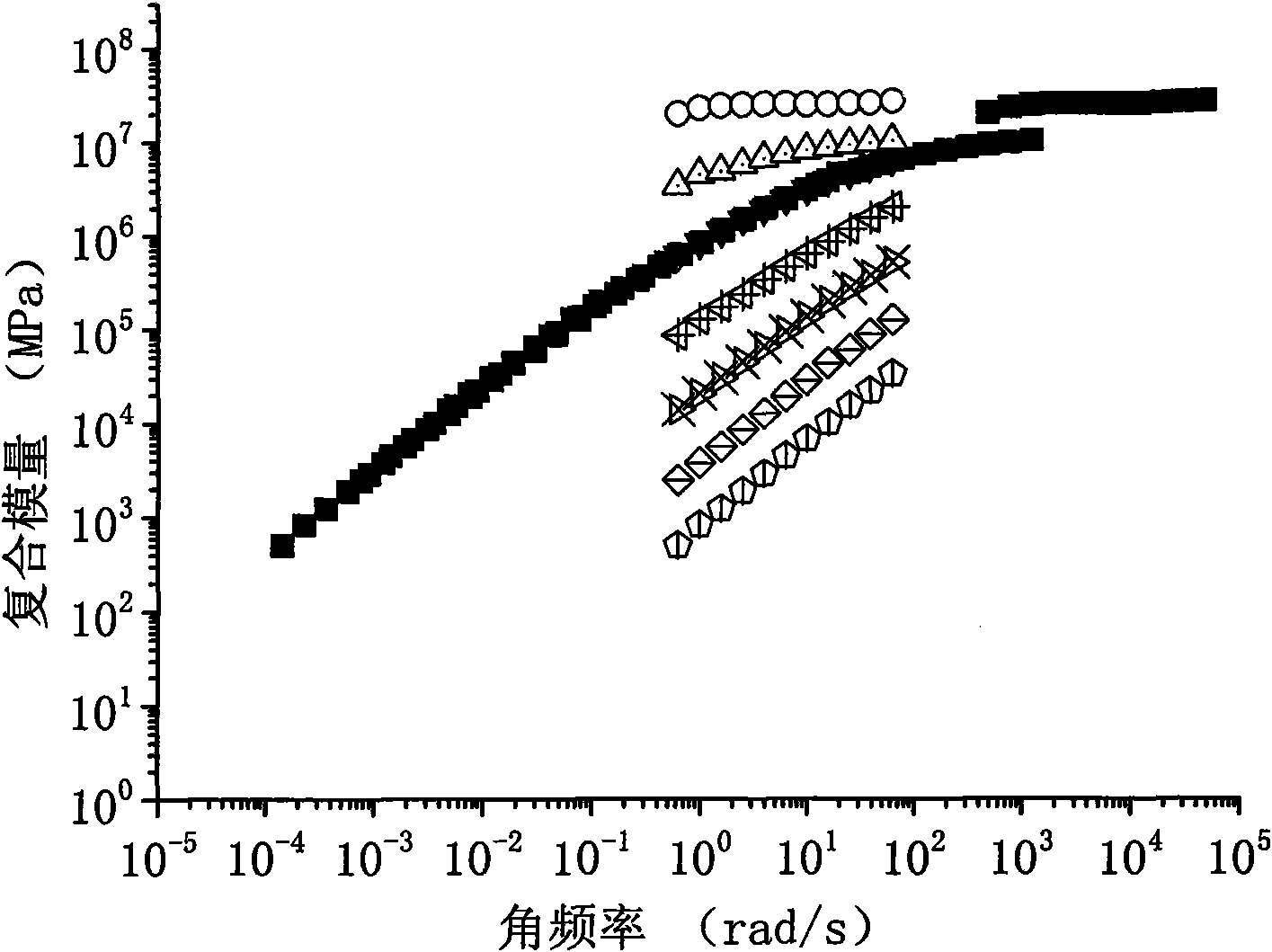

[0011]Specific embodiment one: the method for detecting the aggregated state conversion temperature of asphalt after ultraviolet aging in this embodiment is carried out according to the following steps: one, the asphalt to be detected is heated to a glue state and placed on parallel plates, and the thickness of the asphalt on the parallel plates is 1000μm~2000μm, with 5℃ as the starting temperature, scan the asphalt on the parallel plate at a frequency of 0.1~10Hz, and then scan the asphalt at a frequency of 0.1~10Hz at every interval of n℃, where 0<n≤10, Carry out the last frequency scan until the temperature of the asphalt reaches 63-67°C, draw the composite modulus curves at different temperatures according to the corresponding relationship between the angular frequency and the composite modulus obtained from the scan, where the composite modulus curve is drawn with the angular frequency as the abscissa, Take the composite modulus as the ordinate; 2. Perform time-temperature...

specific Embodiment approach 2

[0015] Embodiment 2: The difference between this embodiment and Embodiment 1 is that in step 1, the asphalt to be tested is heated to a glue state and placed on parallel plates, and the thickness of the asphalt on the parallel plates is 1000 μm. Other steps and parameters are the same as those in Embodiment 1.

[0016] The diameter of the circular parallel plates in this embodiment is 25mm.

specific Embodiment approach 3

[0017] Embodiment 3: The difference between this embodiment and Embodiment 1 is that in step 1, the asphalt to be tested is heated until it is glued and placed on parallel plates, and the thickness of the asphalt on the parallel plates is 2000 μm. Other steps and parameters are the same as those in Embodiment 1.

[0018] The diameter of the circular parallel plates in this embodiment is 8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com