Method for arranging shifting carrying platform of wheels based on rotating shaft fixed type two-dimensional motion and mobile platform

A layout method and fixed technology, applied in the directions of casters, wheels, motor vehicles, etc., can solve the problems of high cost, high technology level, complex structure of the micram wheel, etc., achieve high bearing capacity, easy installation and maintenance, movement Smooth and flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

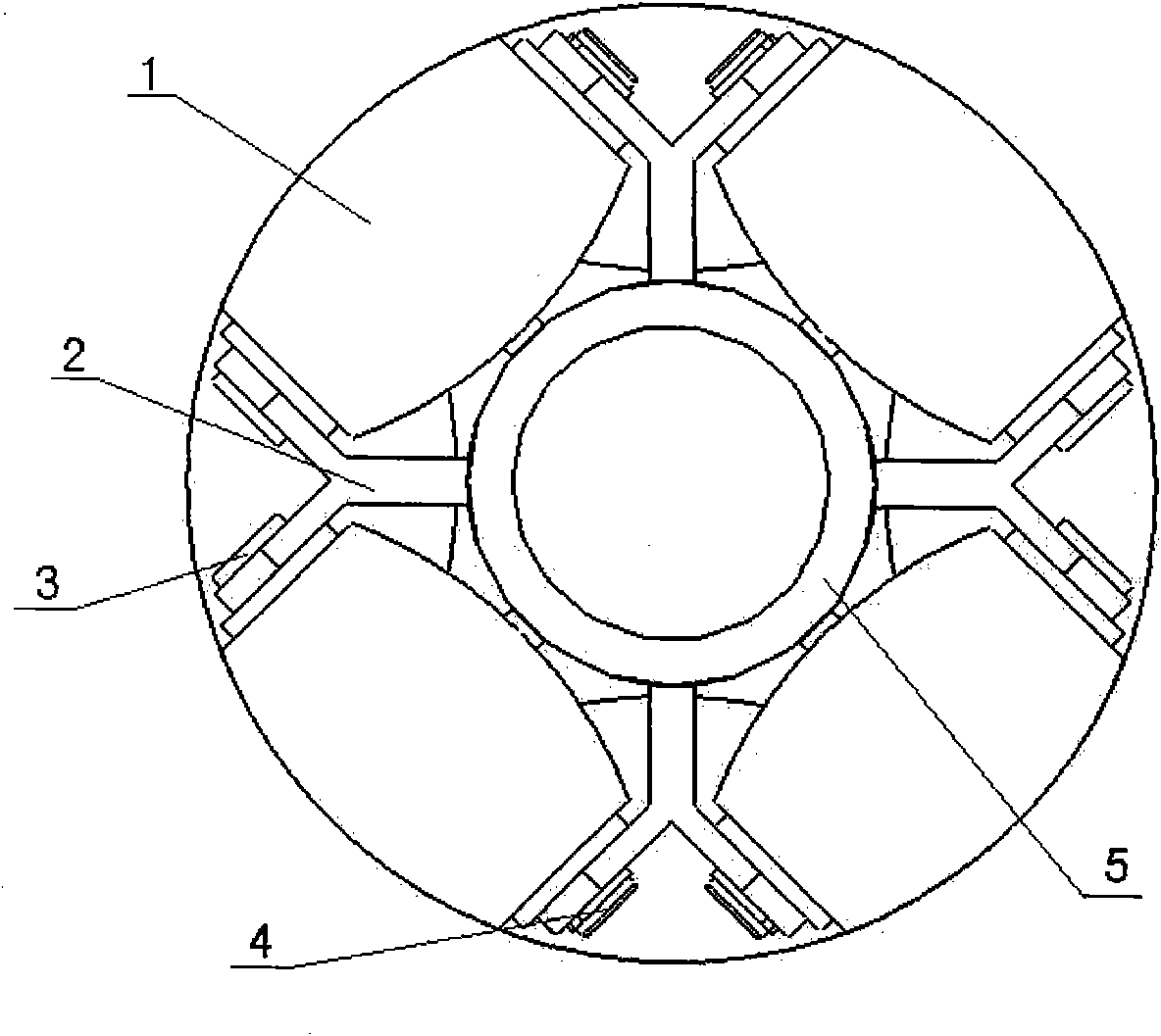

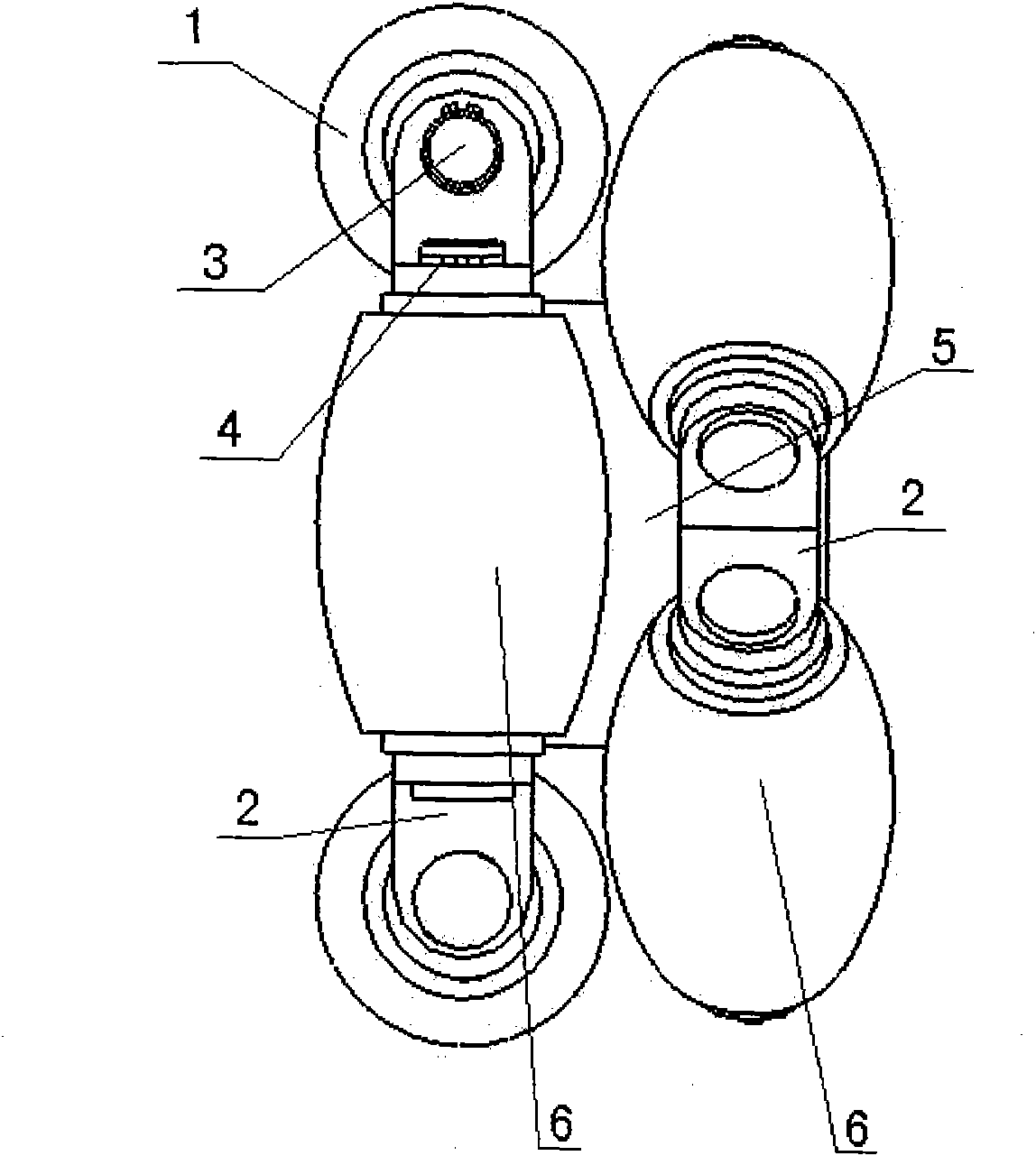

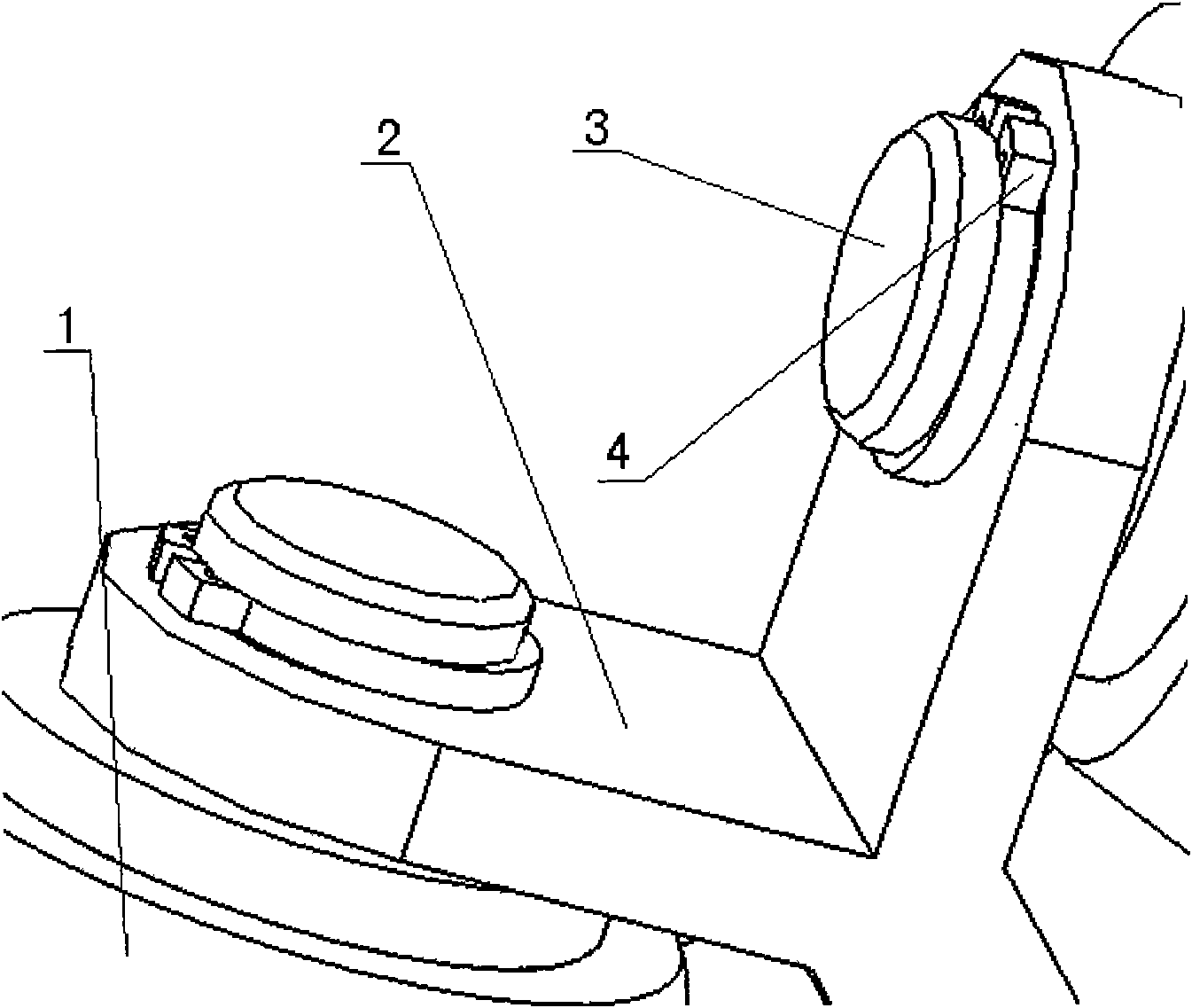

[0020] Attached below figure 1 - attached Figure 4 , to illustrate the two-dimensionally movable runner with a fixed rotating shaft.

[0021] In the runner of this embodiment, the side profile of the sub-wheel is drum-shaped, that is, its working profile is composed of two arcs. The single-row sub-wheel 6 is made up of four sub-wheels 1, and each sub-wheel 1 is installed and connected to the sub-wheel shaft 3 through the sub-wheel frame 2 fixed on the wheel hub 5. For the convenience of installation and maintenance, the sub-wheel shaft 3 is also provided with sub-wheels. Axle limit card 4. The wheel axle of this runner is fixed form, so can not swing phenomenon. The single row of sub-wheel frames is distributed with four sub-wheel frames whose rotating shafts are perpendicular to each other, and the sub-wheels can only rotate along the direction of the wheel axis, thus constituting the degree of freedom of lateral movement. In order to ensure the stability of the movement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com