Combined three-stage efficient desulfurization dust-removal system and method thereof

A high-efficiency technology for desulfurization and dust removal, applied in the direction of combined devices, separation methods, chemical instruments and methods, etc., can solve problems such as instability, short service life, low desulfurization and dust removal effect, achieve stable performance, long service life, and improve desulfurization effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

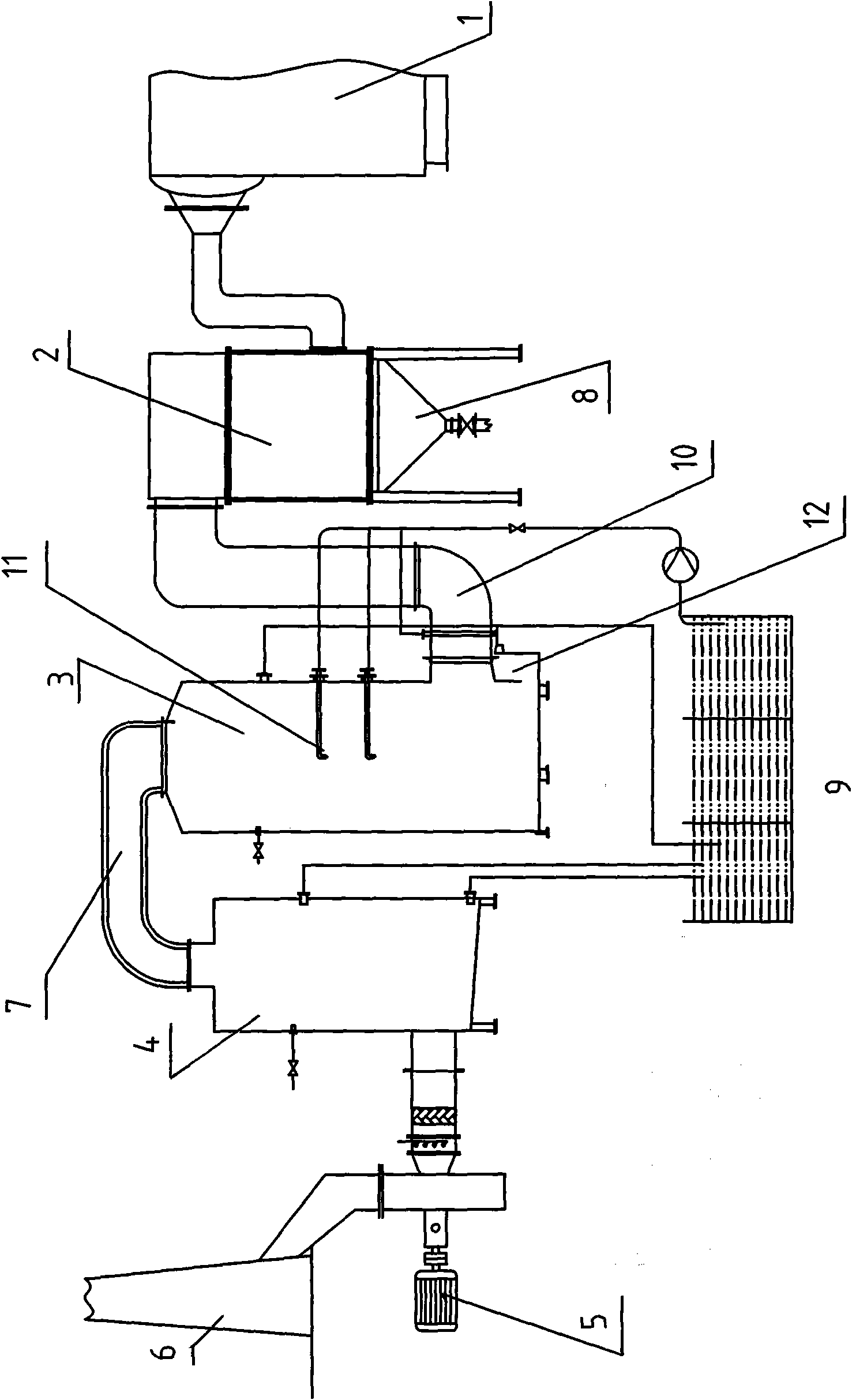

[0024] One of the embodiments of the present invention will be further described below in conjunction with the accompanying drawings. figure 1 It is a structural schematic diagram of the combined three-stage high-efficiency desulfurization and dust removal system of the present invention.

[0025] Such as figure 1 As shown, the combined three-stage high-efficiency desulfurization and dust removal system of the present invention includes a dry dust collector 2, a desulfurization purification tower 3, a centrifugal dehydrator 4, and a lye purification system 9, and a dry dust collector is arranged in sequence between the boiler 1 and the chimney 6 2. Desulfurization purification tower 3. Centrifugal dehydrator 4.

[0026] The lower part of the side of the dry dust collector 2 is provided with a tangential inlet, and the tangential inlet is connected to the outlet of the boiler 1 with the connecting air duct 7. There are several layers in the dry dust collector 2 from the tangen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com