Near-infrared characterizing method for quality change in tobacco silk producing procedures

A near-infrared and tobacco-based technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of sensory quality fluctuation, long chemical analysis cycle, unsuitable for sample process quality evaluation, etc., and achieve stable effect and quality , the effect of short cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

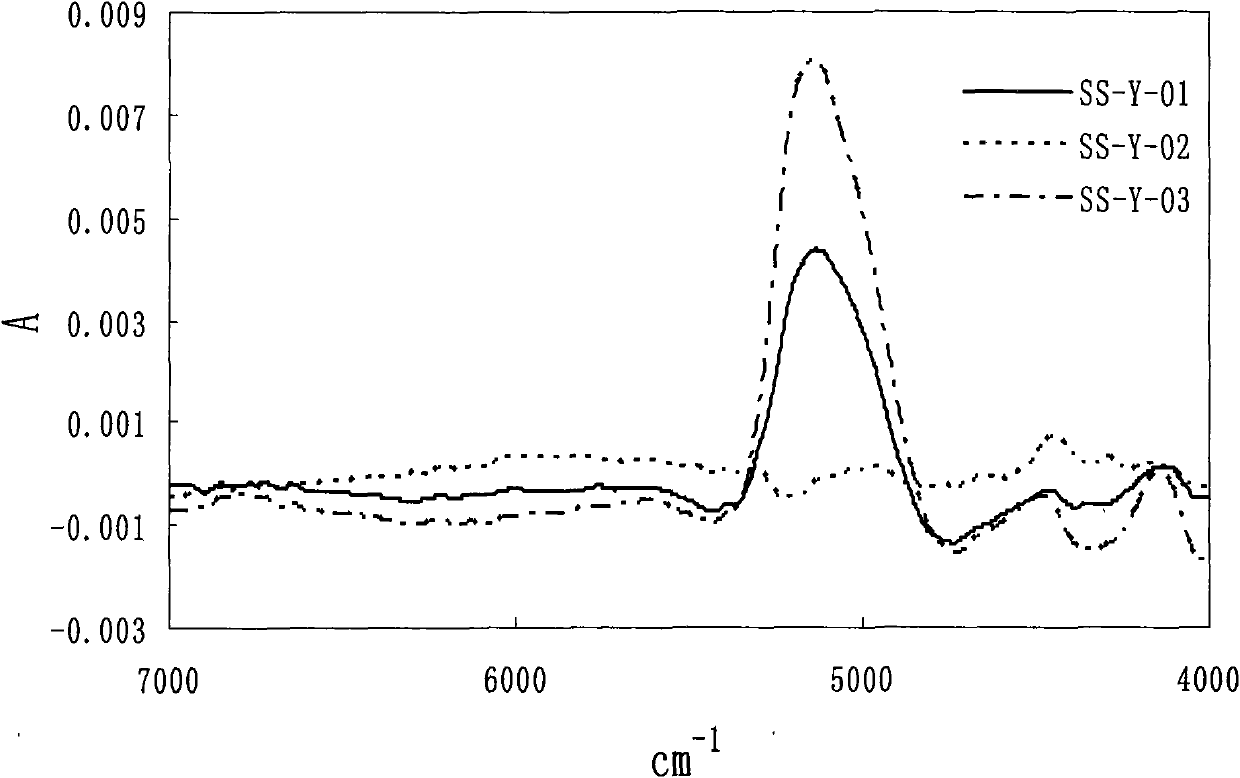

[0021] Near-infrared characterization of tobacco quality changes during the loosening and rehydration process of silk-making threads. Set KB-01 as a blank sample according to step 1, and set SS-01, SS-02, and SS-03 as comparison samples according to step 2. Their respective process parameters are shown in Table 1:

[0022]

[0023]

[0024] Table 1 Loose moisture regain process parameters

[0025] For the blank sample KB-01 and the comparative samples SS-01, SS-02, and SS-03, go through steps 3 to 6: collect the near-infrared Scanning spectrum, acquisition range is 7500cm -1 to 4000cm -1 , subtract the scanning spectrum of the blank sample KB-01 from the scanning spectra of the comparative samples SS-01, SS-02, and SS-03, and obtain the following respectively figure 1 The near-infrared difference spectra of SS-01, SS-02, and SS-03. From figure 1 It can be seen that when the process parameters are different, the near-infrared difference spectra of the comparative sam...

Embodiment 2

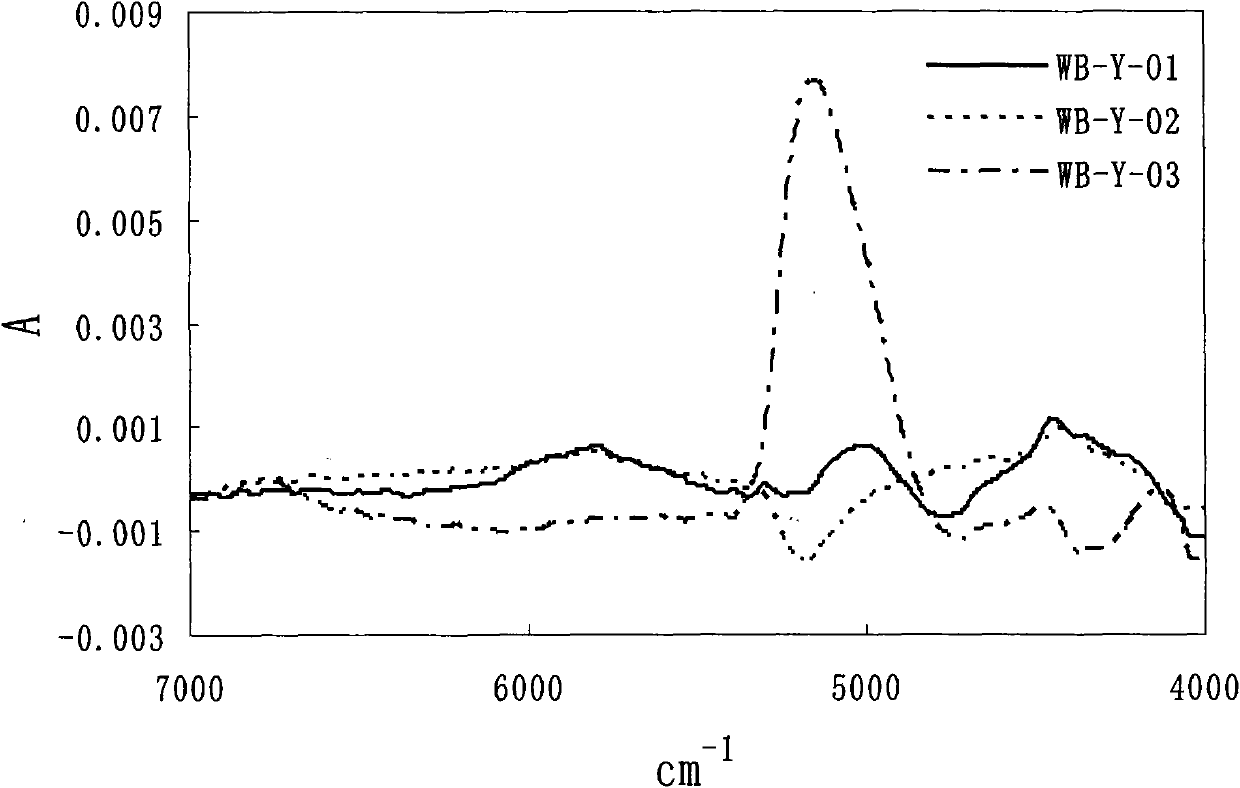

[0027] Near-infrared characterization of tobacco quality changes during the microwave loosening process on the silk-making line. Set KB-02 as a blank sample according to step 1, and set WB-01, WB-02, and WB-03 as comparison samples according to step 2. Their respective process parameters are shown in Table 2:

[0028]

[0029]

[0030] Table 2 Microwave Loose Process Parameters

[0031] For the blank sample KB-02 and the comparative samples WB-01, WB-02, and WB-03, go through steps 3 to 6: collect the near-infrared Scanning spectrum, acquisition range is 9000cm -1 to 4000cm -1 , subtract the scanning spectrum of the blank sample KB-02 from the scanning spectrum of the comparative samples WB-01, WB-02, and WB-03, and obtain the following respectively figure 2 The near-infrared difference spectrum of WB-01, WB-02, WB-03. From figure 2 It can be seen that when the process parameters are different, the near-infrared difference spectra of the comparison samples WB-01, ...

Embodiment 3

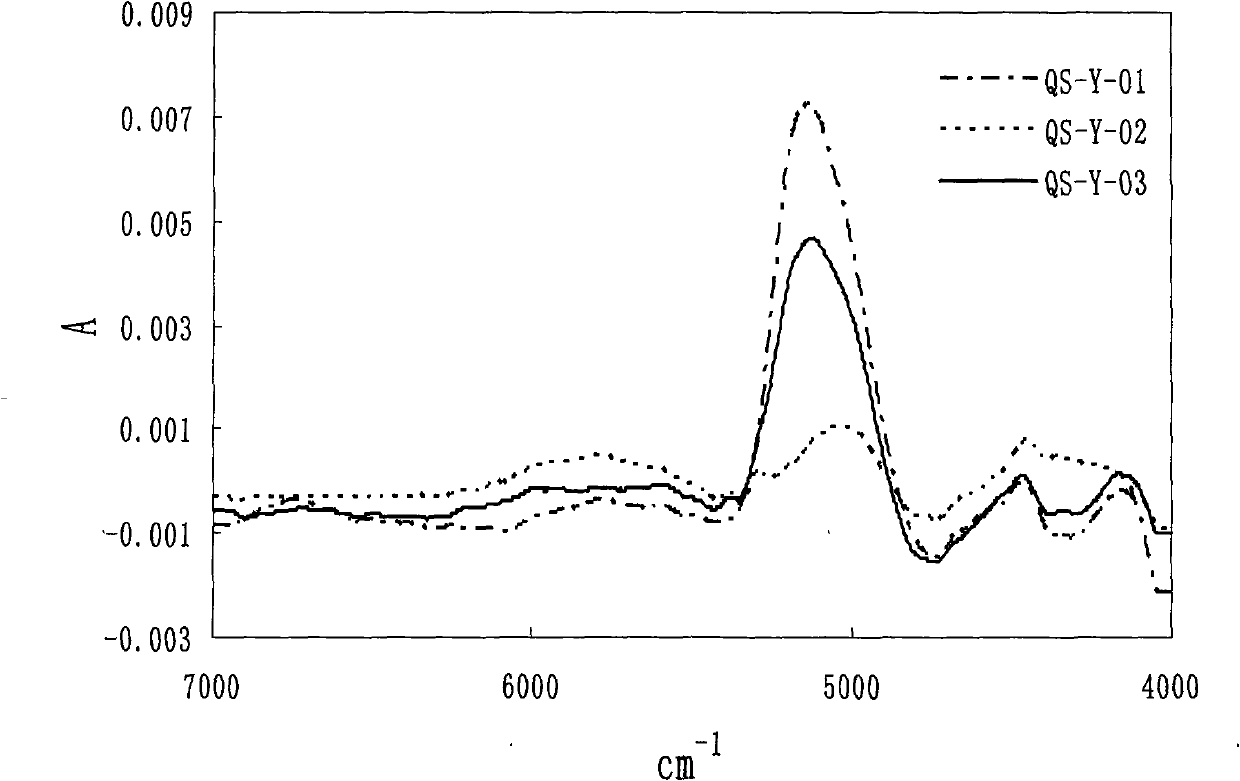

[0033] Near-infrared characterization of changes in tobacco quality during the wire-cutting process. Set KB-03 as a blank sample according to step 1, and set QS-1, QS-2, and QS-3 as comparison samples according to step 2, and their respective process parameters are shown in Table 3:

[0034]

[0035]

[0036] Table 3 Shredded Process Parameters

[0037] For the blank sample KB-03 and the comparative samples QS-1, QS-2, and QS-3, go through steps 3 to 6: collect the near-infrared Scanning spectrum, acquisition range is 7000cm -1 to 4500cm -1 , subtract the scanning spectrum of the blank sample KB-03 from the scanning spectrum of the comparative samples QS-01, QS-02, and QS-03, and obtain the following respectively image 3 The near-infrared difference spectrum of QS-01, QS-02, QS-03. From image 3 It can be seen that when the process parameters are different, the near-infrared difference spectra of the comparison samples QS-01, QS-02, and QS-03 have obvious differenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com