Tensioner assembly comprising a displaceable tensioning rail

A technology for tensioning slide rails and tensioners, which is applied to transmission devices, belts/chains/gears, mechanical equipment, etc., to achieve the effect of saving construction space and increasing construction space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

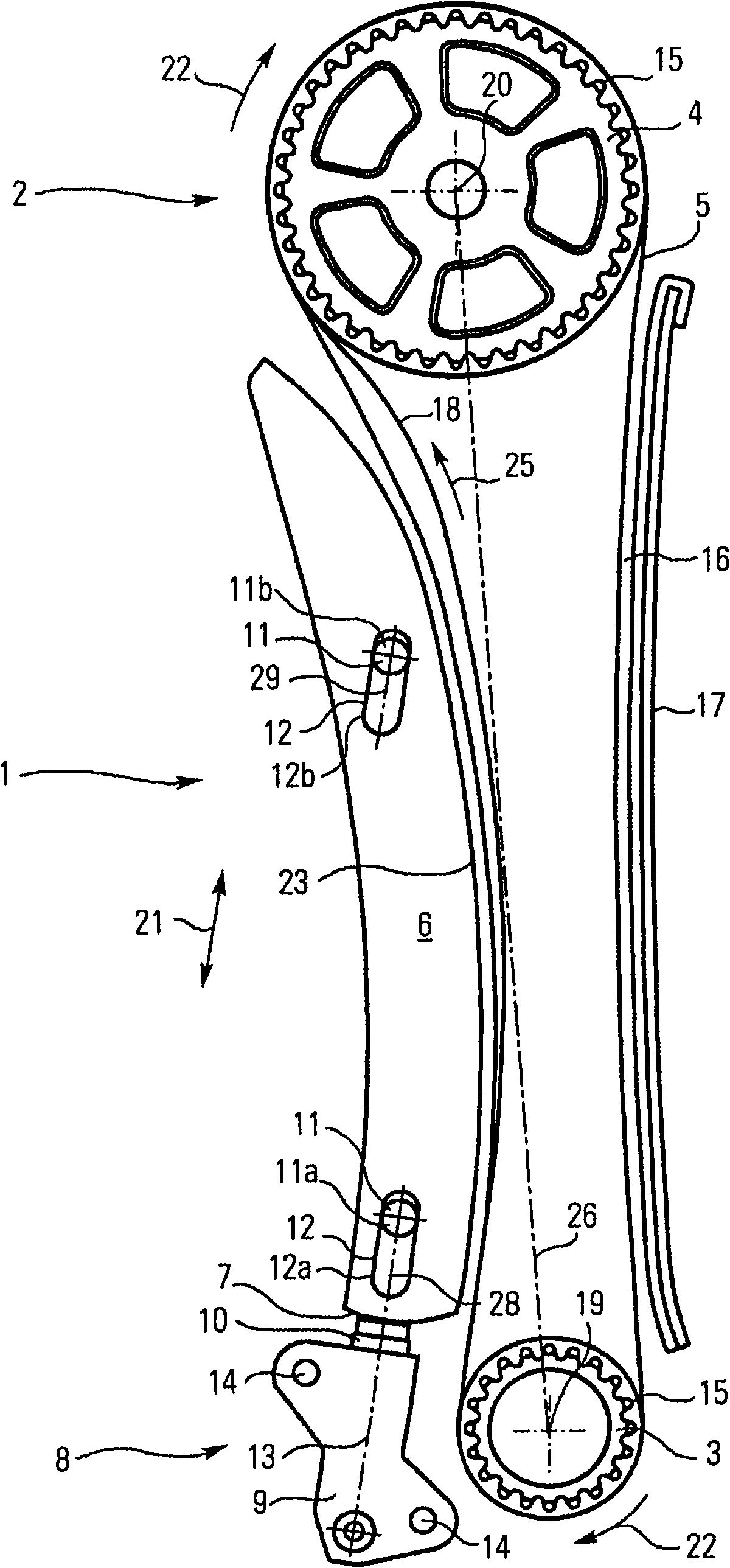

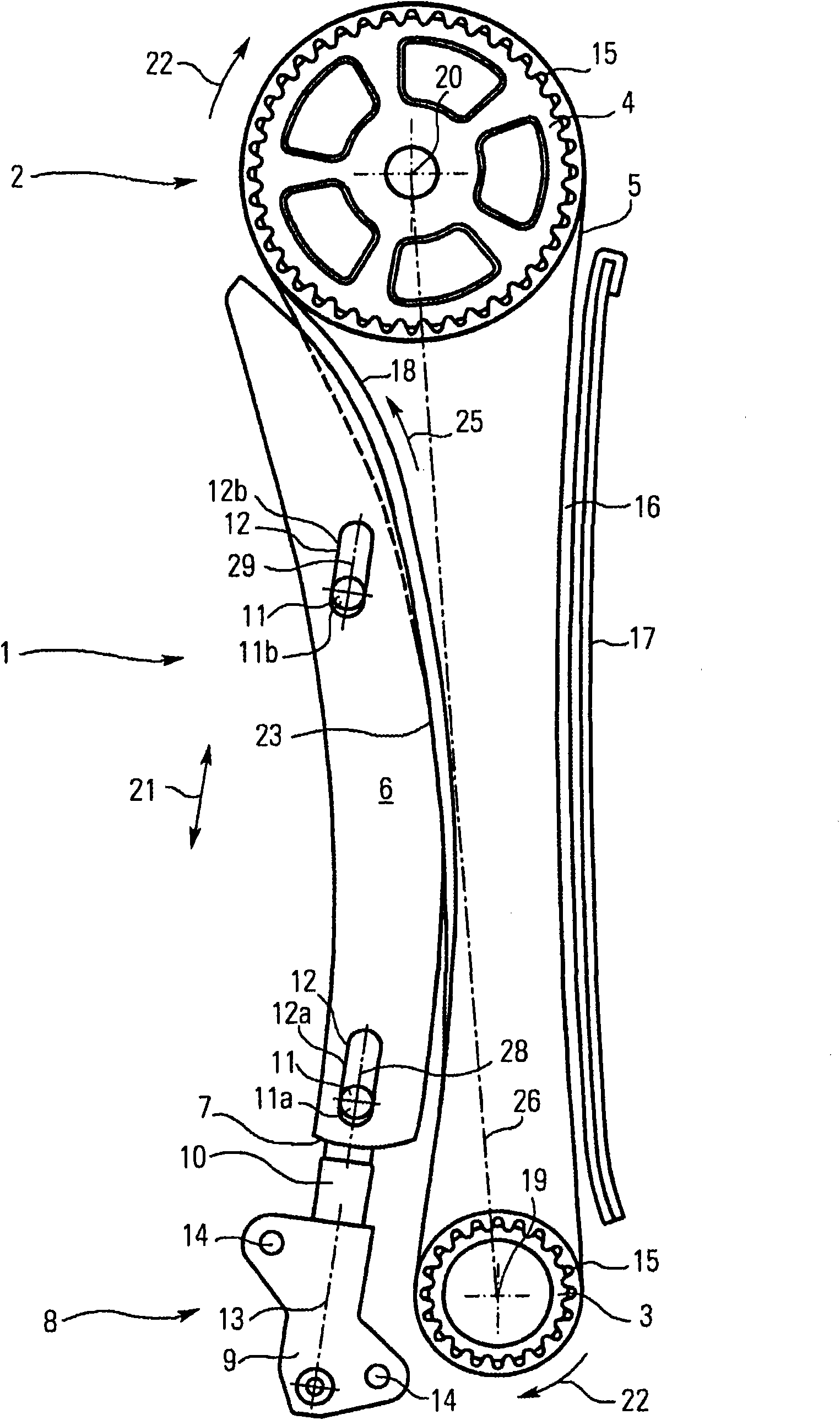

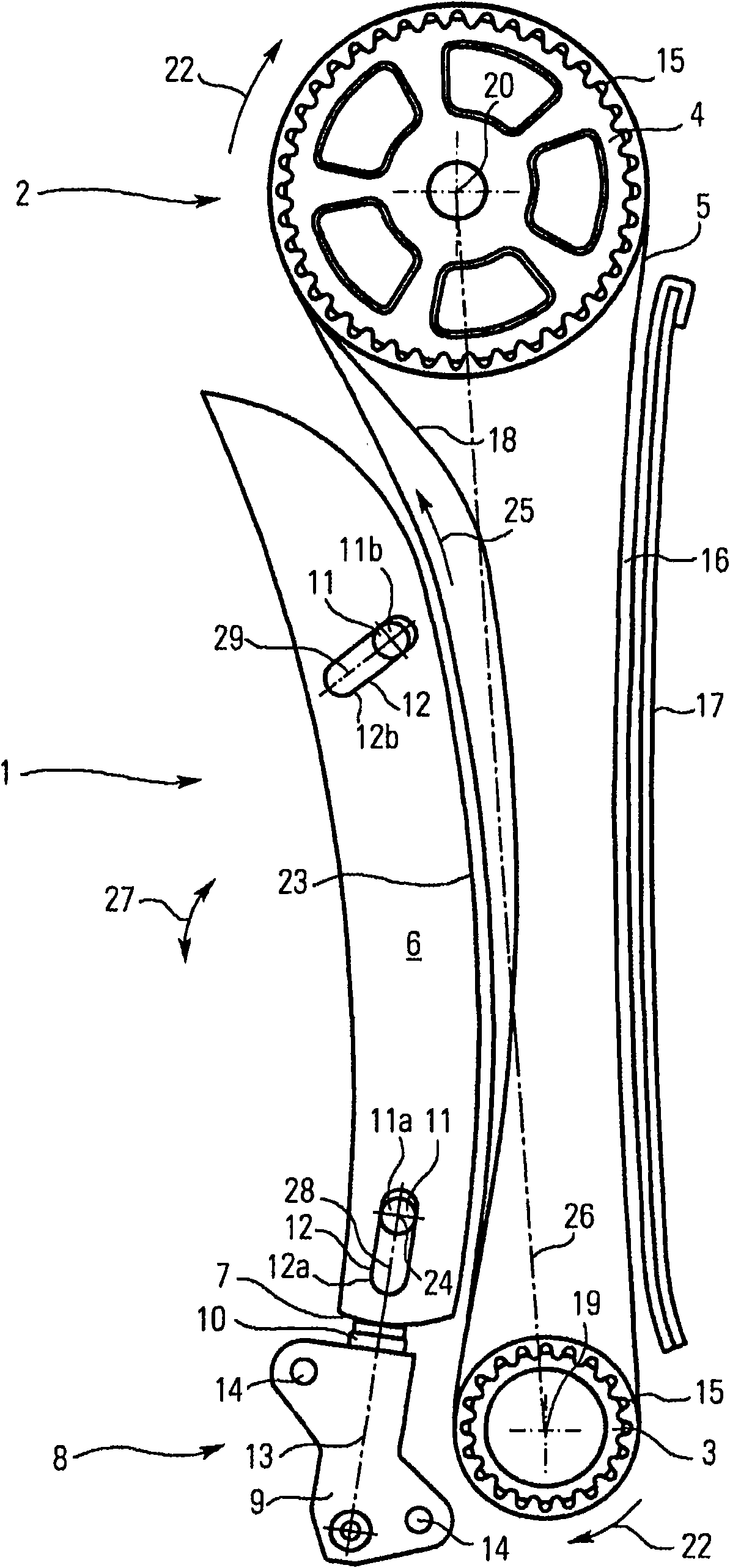

[0026] The tensioner assembly basically consists of a tensioning rail 6 with a curved running surface 23 and a tensioning device 8 . The tensioning device 8 is arranged to extend the tensioning slide 6 . The tensioning piston 10 of the tensioning device 8 is in contact with the tensioning slide 6 via the operating surface 7 . In the illustrated embodiment, the tensioning device 8 comprises a housing 9 in which a tensioning piston 10 is movably mounted. The housing 9 may be fixed to the crankcase or to the engine compartment via the fixing points 14 or in any other way.

[0027] In addition to the chain tensioner illustrated in the figures with a tensioning piston, other tensioners, such as leaf springs or torsion springs, respectively, can also be used.

[0028] The tensioning slide 6 comprises two guide contours 12 through which slide guides 11 designed as bolts 11a, 11b extend. In the illustrated embodiment, the guide profile 12 is formed as mutually spaced oblong holes 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com