Polarizing plate and liquid crystal display unit

A technology of polarizing plates and polarizing plates, applied in the fields of polarizing plates and liquid crystal display devices, capable of solving problems such as deformation of polarizing plates and changes in hue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

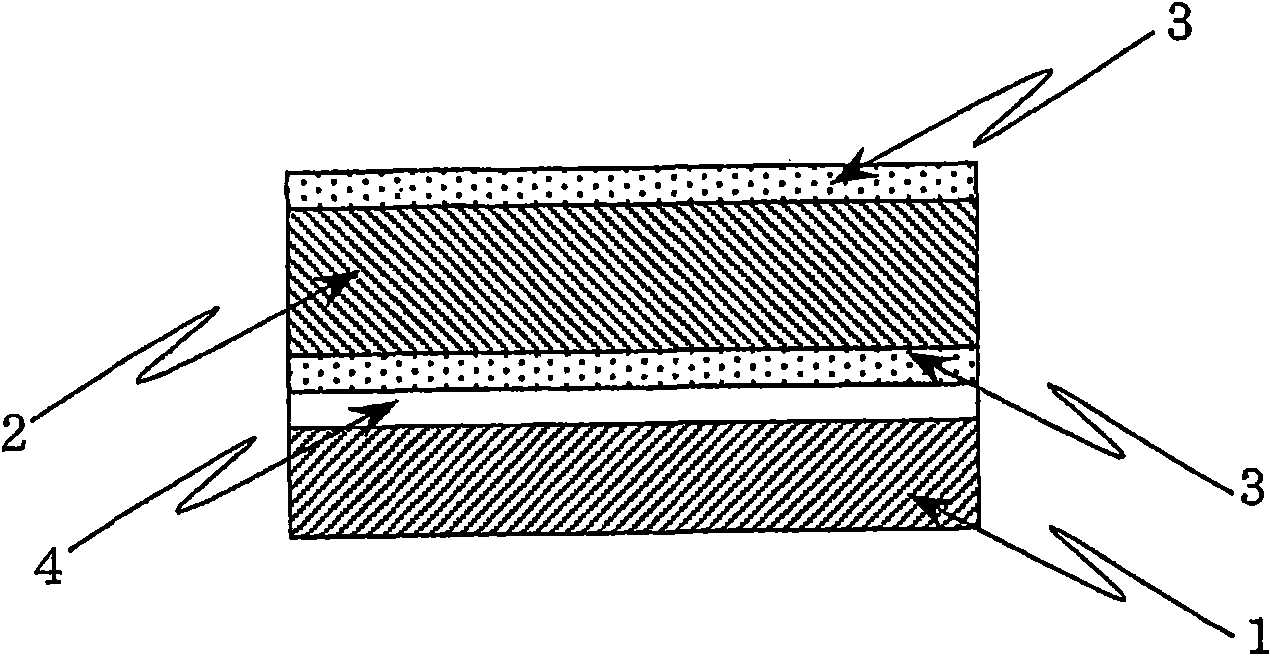

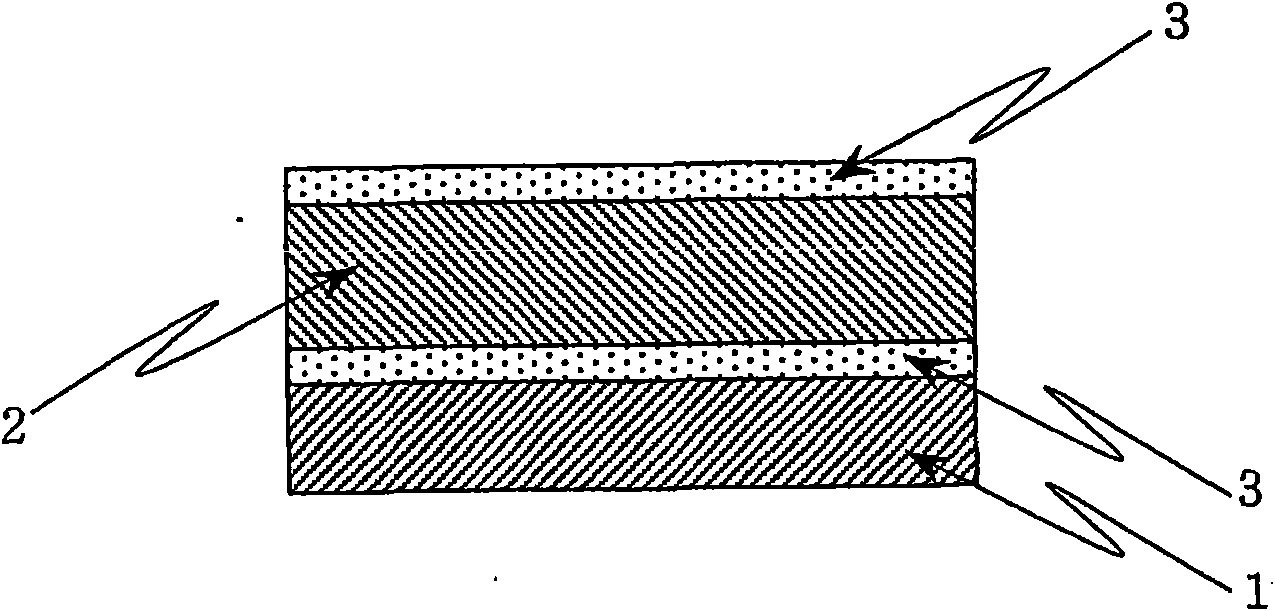

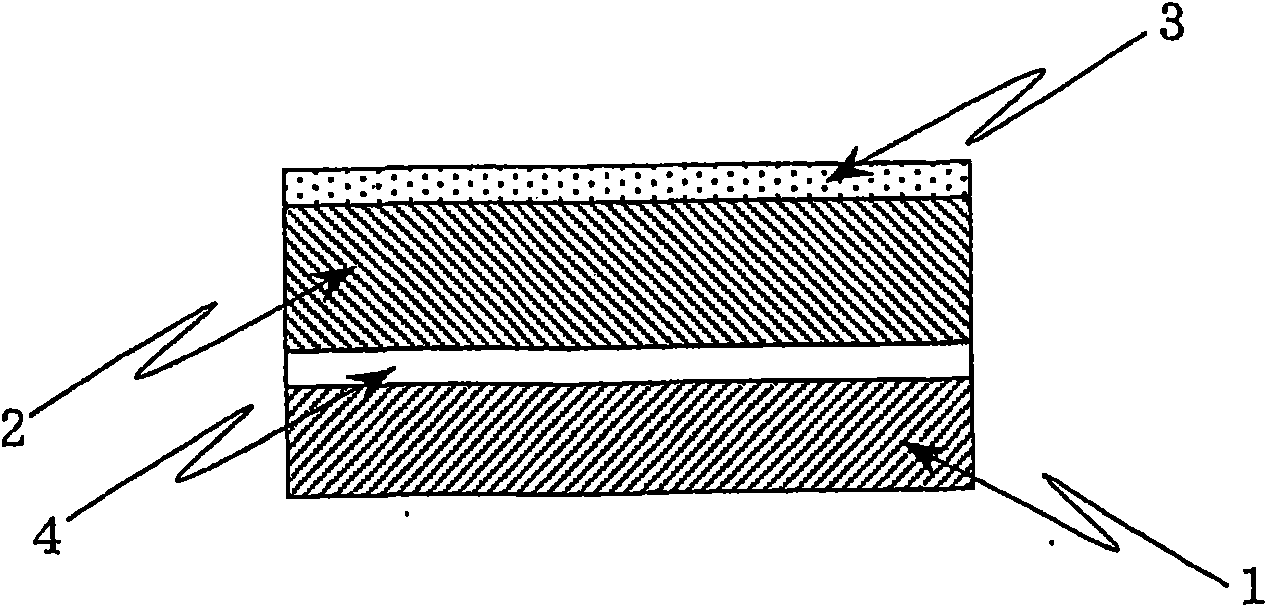

Image

Examples

Embodiment 1

[0072] (a) Fabrication of a protective film having an inorganic particle layer

[0073] Weigh 650 g of Nissan Chemical Co., Ltd. silica gel (SNOWTEX (SNOWTEX) ST-XS (the average particle diameter measured by the Hills method is 4 to 6 nm, and the solid content concentration is 20% by weight)), 1300 g of Nissan Chemical Co., Ltd. The company's silica gel (Snodix ST-ZL) (average particle diameter measured by laser diffraction scattering method: 78nm, solid content concentration: 40wt%)) was mixed with 4550g of water and stirred to prepare an inorganic fine particle dispersion . This inorganic fine particle dispersion liquid was coated on a triacetyl cellulose film (thickness: 80 μm, in-plane Phase difference: 1 nm), dried at 60°C. The coating and drying operations were further performed 9 times on the laminated body to obtain a protective film in which the inorganic fine particle layer was laminated on the thermoplastic resin layer. The thickness of the inorganic fine particl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com