Water-saving type pipe joint and opening or closing method

A pipe joint and water-saving technology, applied in the field of pipe joints, can solve problems such as poor water saving and unreasonable structural design, and achieve the effect of less consumables and obvious water-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

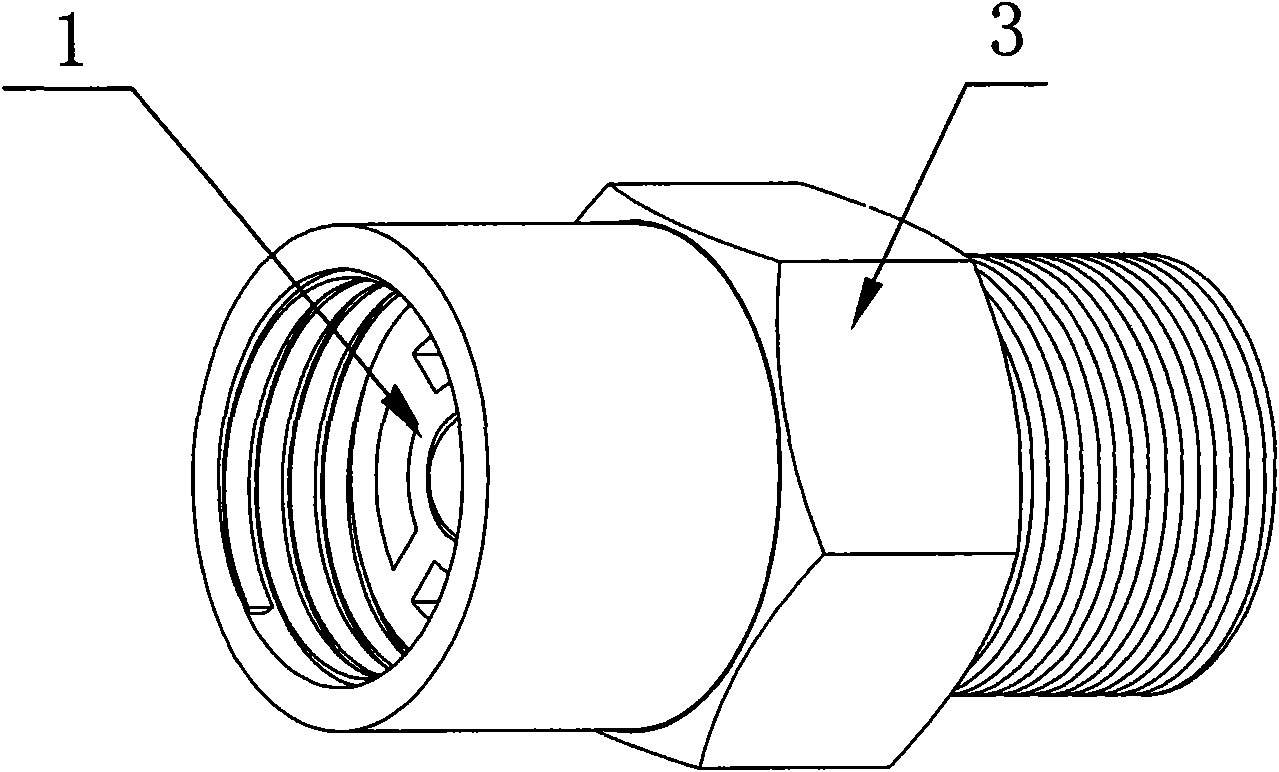

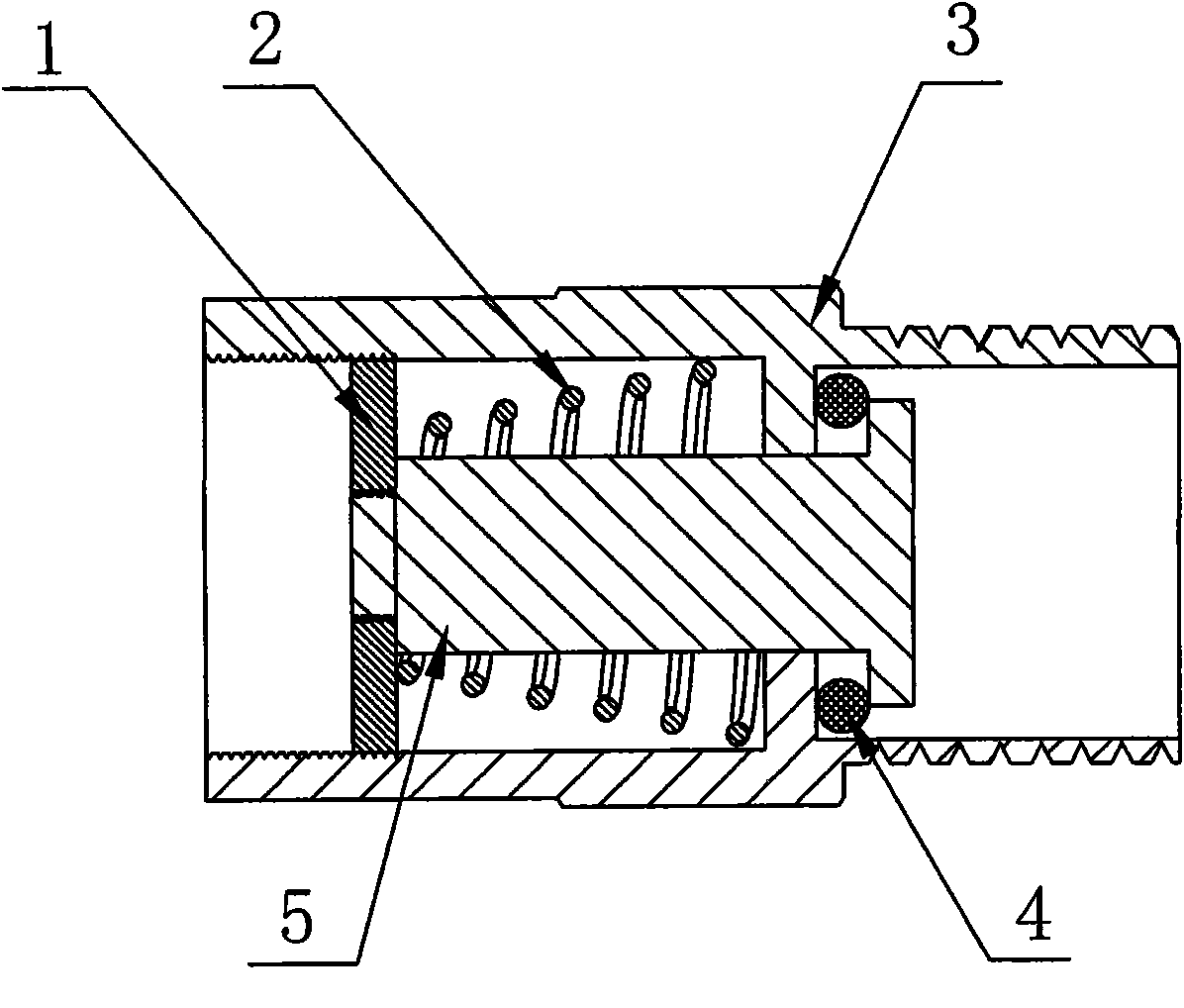

[0022] Now in conjunction with the above accompanying drawings, the present invention will be further described. The present invention has few parts and consists of a valve plate 1, a spring 2, a pipe body 3, a sealing ring 4 and a valve core 5. When the dual function of pipe joint and valve is implemented, the internal thread at one end of the valve body is connected with the external thread of the water pipe, that is, the screw hole of the valve plate is connected with the "T"-shaped vertical external thread of the valve core, and the sealing ring is against the gap of the through hole. Plate, the spring connected to the "T" vertical section of the spool is stretched and this end is connected to the outer thread of the external water pipe; when the water side joint is screwed into the inner thread of the other end of the pipe body, the screwed end pushes the valve plate, Water flows in from the valve hole on the radial surface of the valve plate, and flows out from the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com