Multi-pressure shared type gas tank and pressure-supplementing valve thereof

A pressure-compensating valve and gas tank technology, applied in mechanical equipment and other directions, can solve problems such as unfavorable industrial field application and increase the space occupied by equipment, and achieve the effects of reducing equipment space occupancy, flexible installation and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below.

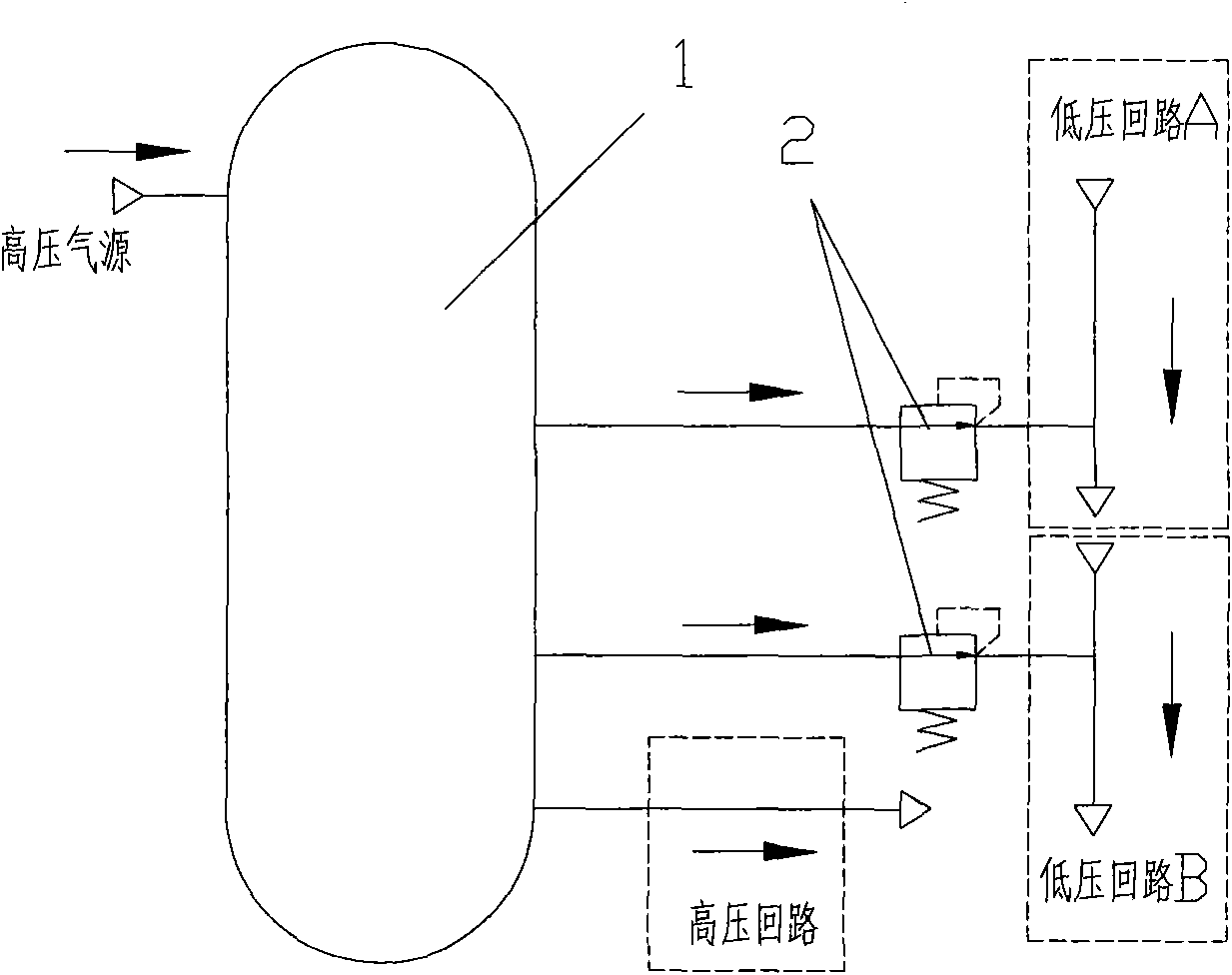

[0015] figure 1 It is a structural diagram of a multi-pressure shared gas tank. In the figure, the gas tank (1) has multiple exhaust ports. The gas tank (1) is connected in series with the high-pressure gas circuit. Valve (2) is connected, when the difference between the pressure at the exhaust port of the gas tank and the pressure of the low-pressure circuit is less than a certain set value, the supplementary pressure valve (2) is completely closed, and no air flows through; the exhaust port of the gas tank (1) When the difference between the pressure and the pressure of the low-pressure air circuit is greater than a certain set value, the pressure supplement valve (2) is opened, and the opening of the valve is automatically enlarged, and the air in the gas tank is supplied to the low-pressure circuit A / B. Thereby reducing the pressure pulsation of the low pressure circuit.

[0016] 2. The principle of setting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com