Manufacturing technique of amantadine hydrochloride and special equipment thereof

A technology of amantadine hydrochloride and special equipment, applied in chemistry/physics/physicochemistry stationary reactors, purification/separation of amino compounds, organic chemistry, etc., which can solve the problem of increased explosion hazard, increased investment cost, and difficult operation To reduce the number of operators, improve production safety, and avoid material pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

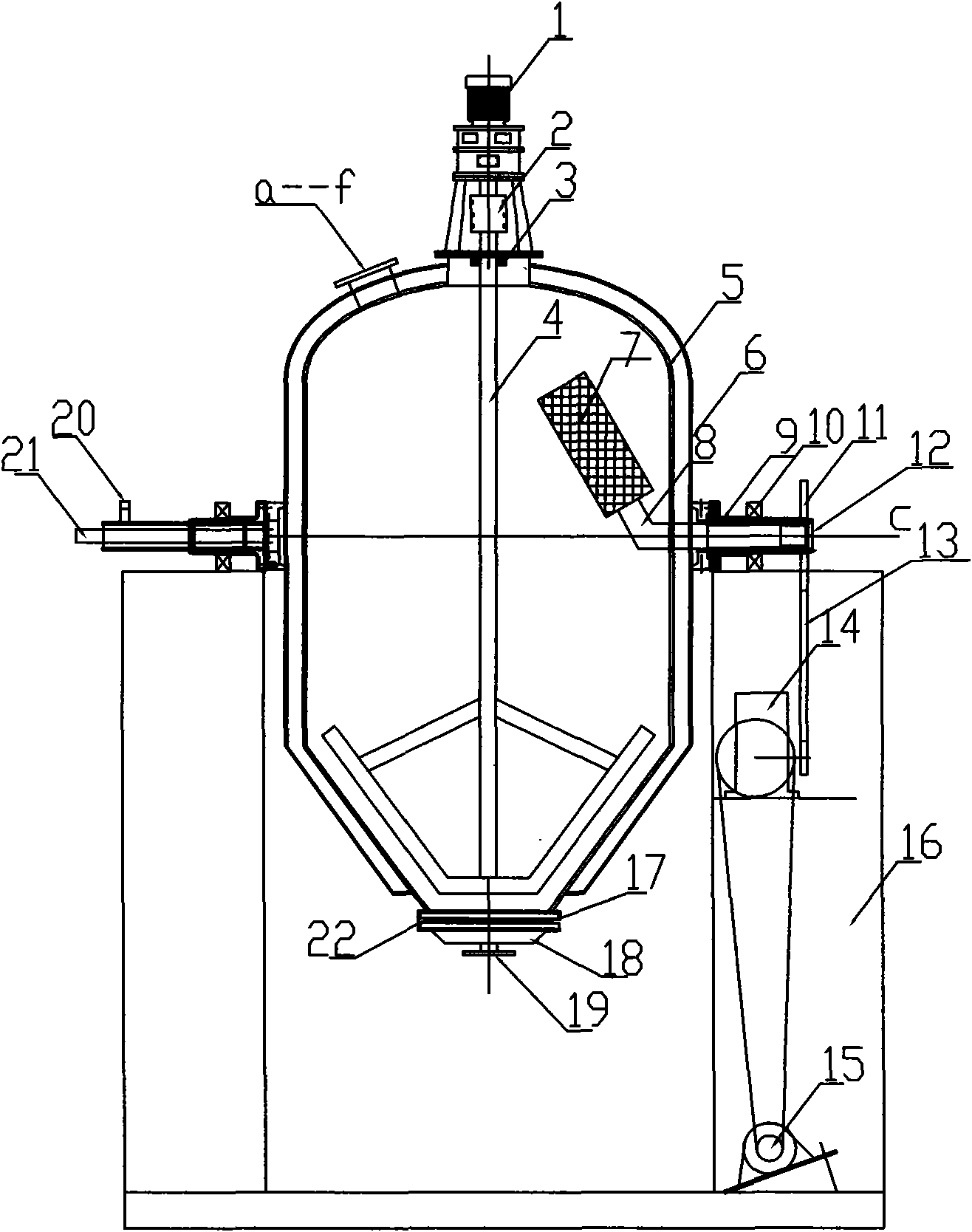

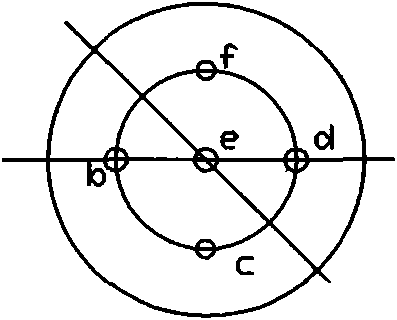

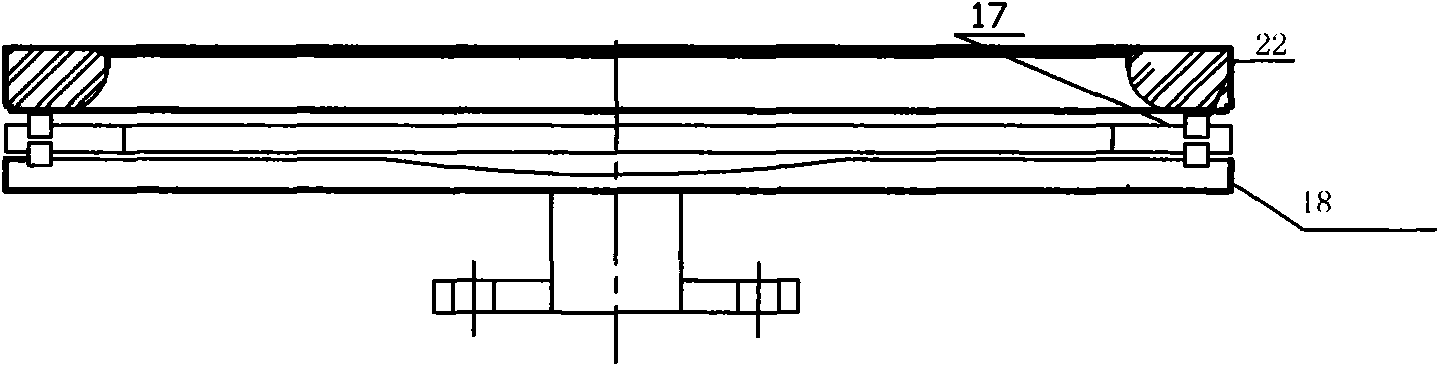

[0025] Such as Figure 1-4 As shown, the special equipment for amantadine hydrochloride of the present invention includes: a tank body is composed of an enamel inner wall 5 and a jacket outer wall 6, and a transmission assembly is composed of a base 16, a reducer 14, a rotary motor 15, a transmission chain 13 and a transmission sprocket 11. , There are valves and nozzles on the tank. The specific improvement is as follows: a mixing motor 1 is fixedly installed at the upper end of the tank body, a stainless steel or titanium mixing blade 4 is arranged in the tank body, and the mixing blade 4 is an anchor type or a frame type structure. The upper end of the stirring paddle 4 penetrates the tank body and is connected to the coupling 2 provided on the tank body. The coupling 2 is connected to the stirring motor 1. The rotation of the stirring motor shaft drives the stirring paddle 4 to rotate in the tank body to achieve stirring. The function of the material, the stirring blade 4 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com