Robot for pouring aluminum piston

A robot and pouring machine technology, which is applied to manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of fluctuating aluminum piston blank casting quality, high scrap rate, complex structure, etc., and achieve reduced labor intensity, low cost, and improved The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

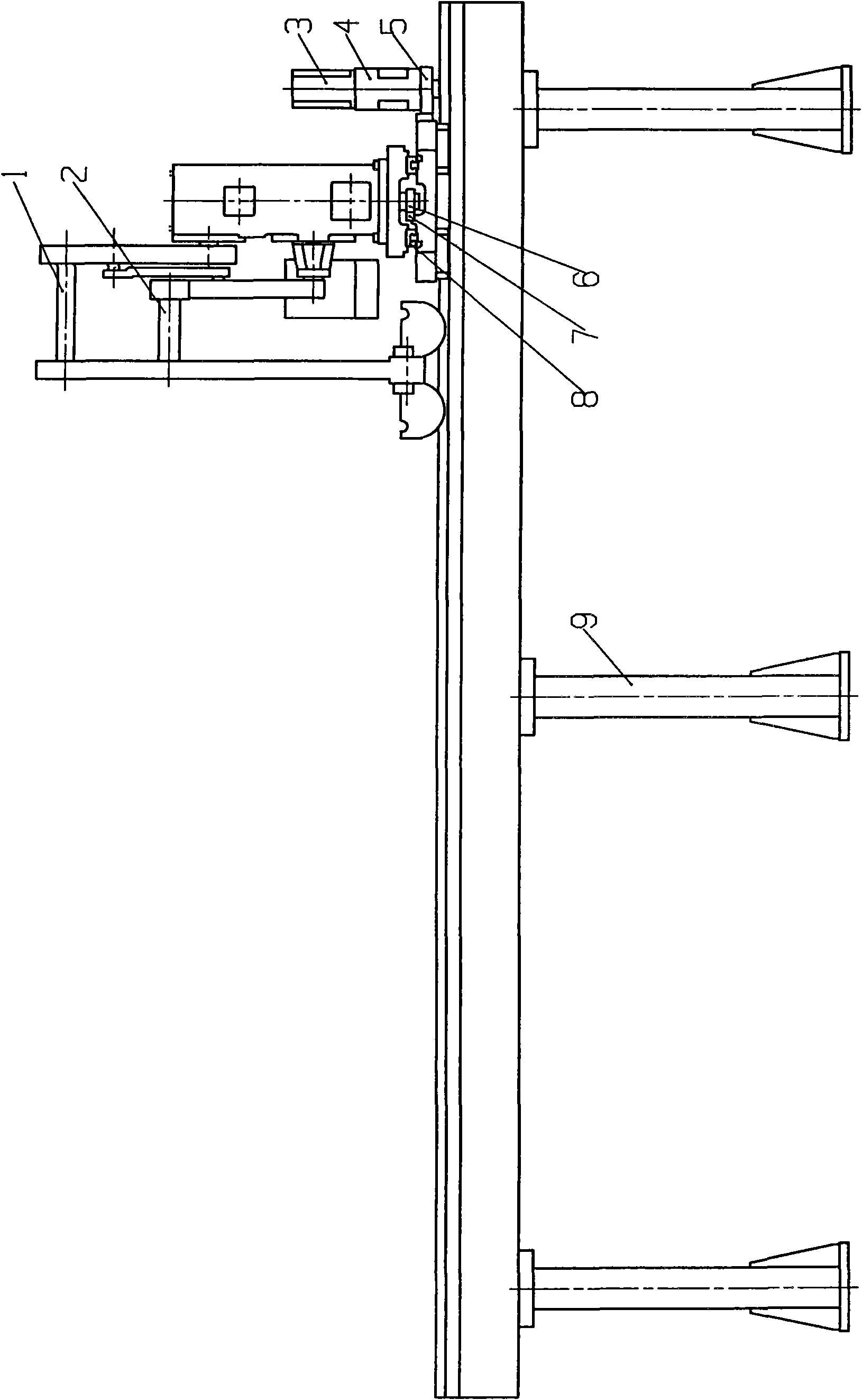

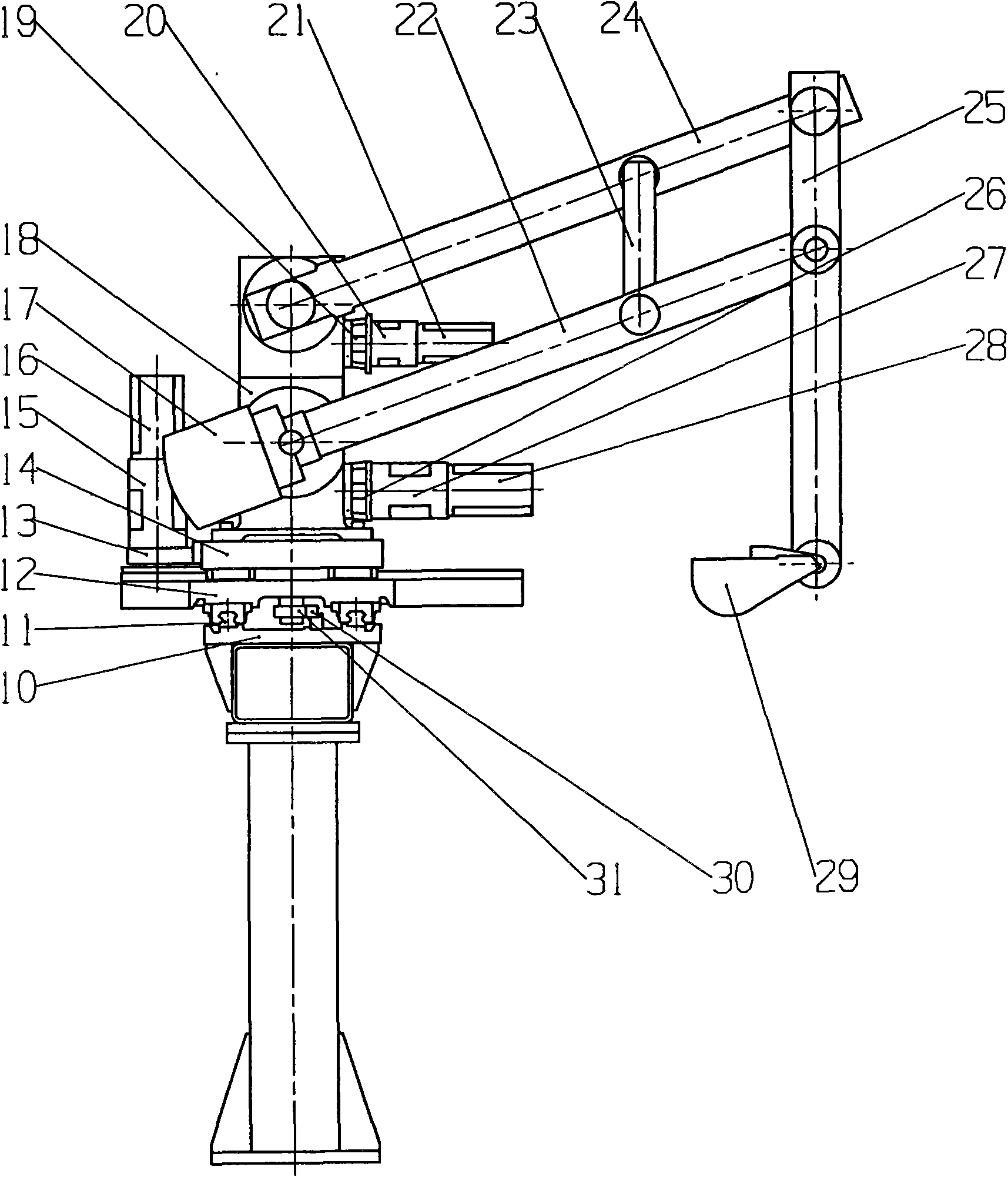

[0013] Such as figure 1 and figure 2 As shown, the aluminum piston pouring robot of the present invention includes a Z-axis servo motor 3, an X-axis servo motor 16, a Y-axis servo motor 28 and an A-axis servo motor 21, and these four servo motors drive the pouring spoon 29 to move along four degrees of freedom , realize pouring spoon 29 to select casting machine and holding furnace, follow-up, transport aluminum liquid, scoop quantitative and pour aluminum liquid and other actions to replace manual pouring, so as to reduce the influence of human factors on the quality of aluminum piston casting.

[0014] A beam 10 is fixed on the bracket 9 . Two linear guide rail pairs 11 are installed on the beam 10, and a cross slide 12 is installed on the linear guide rail pairs 11. The Z-axis servo motor 3 is connected with the reducer 4 and fixed on the cross slide 12 through the motor base 5 . A gear 31 is installed on the output shaft of the reducer 4 , and the gear 31 meshes with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com