TFT-LCD array substrate and methods for manufacturing and testing same

An array substrate and substrate technology, applied in the field of TFT-LCD array substrate and its manufacturing and testing, can solve the problems of inability to test signals in the liquid crystal panel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

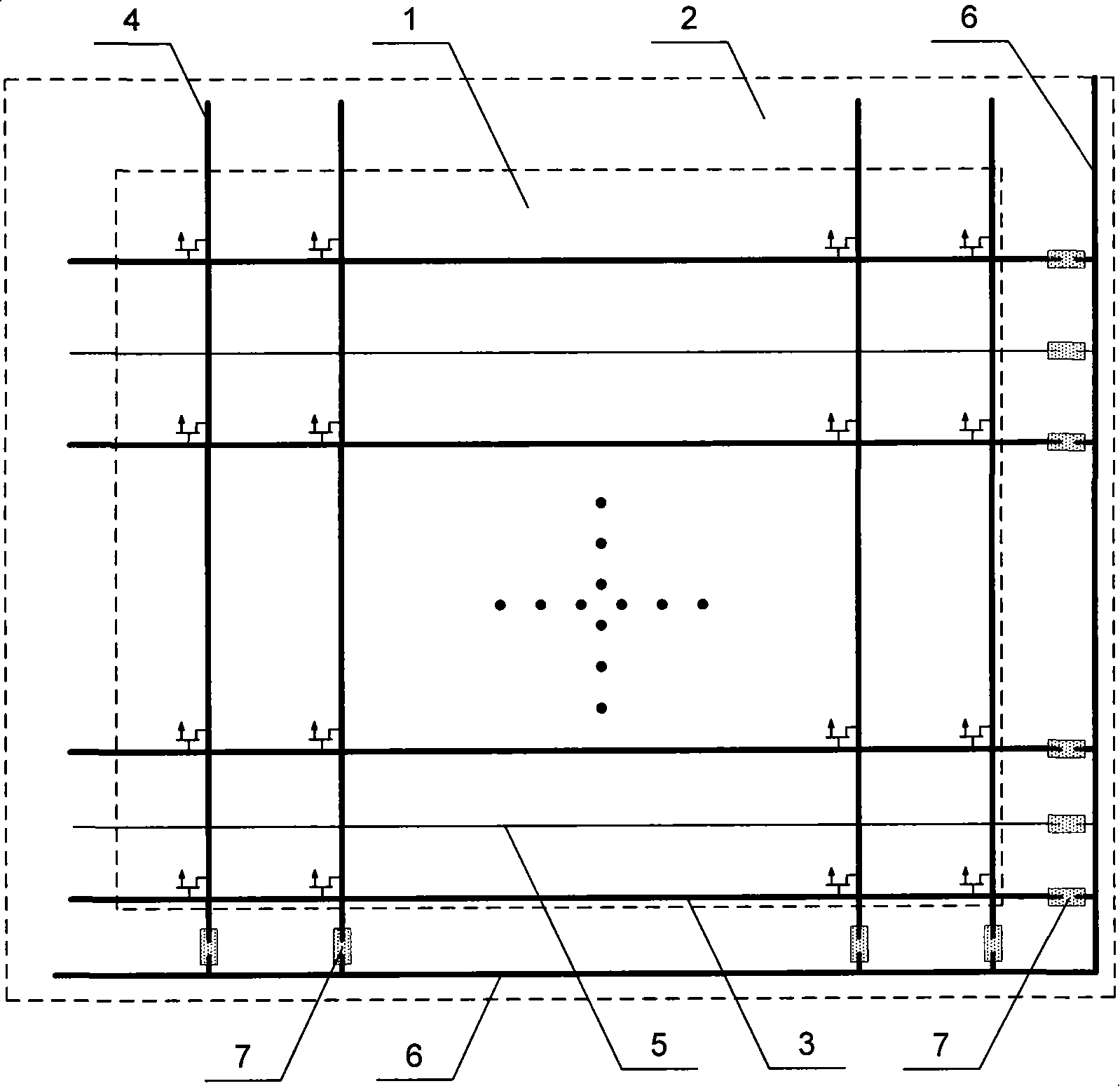

[0041] On the basis of the above-mentioned technical scheme, several common electrode lines 5 can also be formed in the display area 1, and joint points 7 can also be set between the common electrode lines 5 and the test lines 6, which are used to connect the test lines 6 and the common electrodes during testing. Line 5 is connected. Therefore, in this embodiment, the connection point 7 can be arranged at the end of the gate line 3, the data line 4 and / or the common electrode line 5, and is used to connect the test line 6 to the gate line 3 and connect the test line 6 to the data line during testing. 4. Connect and / or connect the test line 6 with the common electrode line 5.

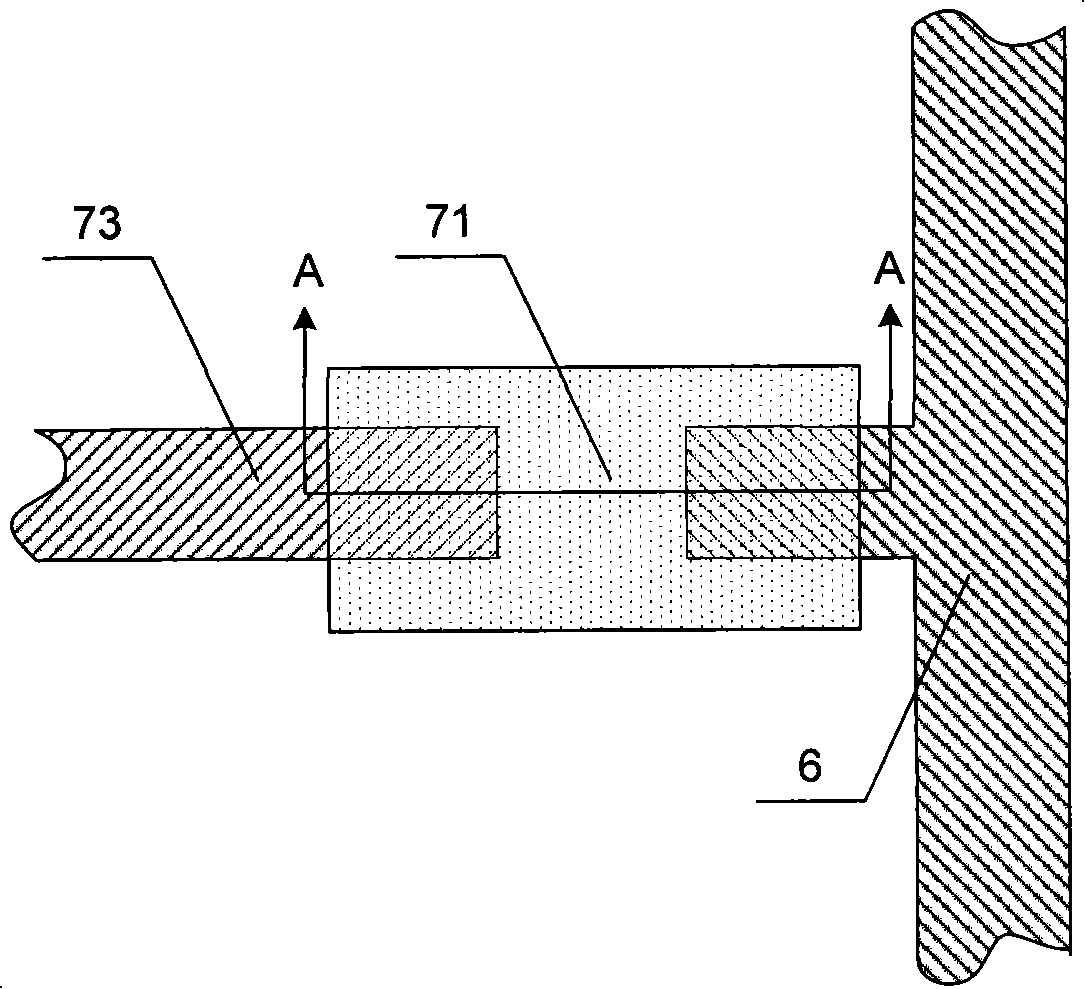

[0042] figure 2 It is a plan view of the bonding point in the TFT-LCD array substrate of the present invention. like figure 2 As shown, the main structure of the bonding point 7 includes a conductive connection layer 71, and the conductive connection layer 71 on the same layer as the pixel electrode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com