Separate magnetic circuit permanent magnetic mechanism contactor and control unit thereof

A permanent magnet mechanism and control unit technology, applied in electromagnetic relays, electromagnetic relay details, circuits, etc., can solve the problems of enhancing the closing ability of permanent magnet contactors, small opening pulse current, and large closing pulse current, etc. Achieve significant energy-saving effect, prolong closing current time, and enhance closing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

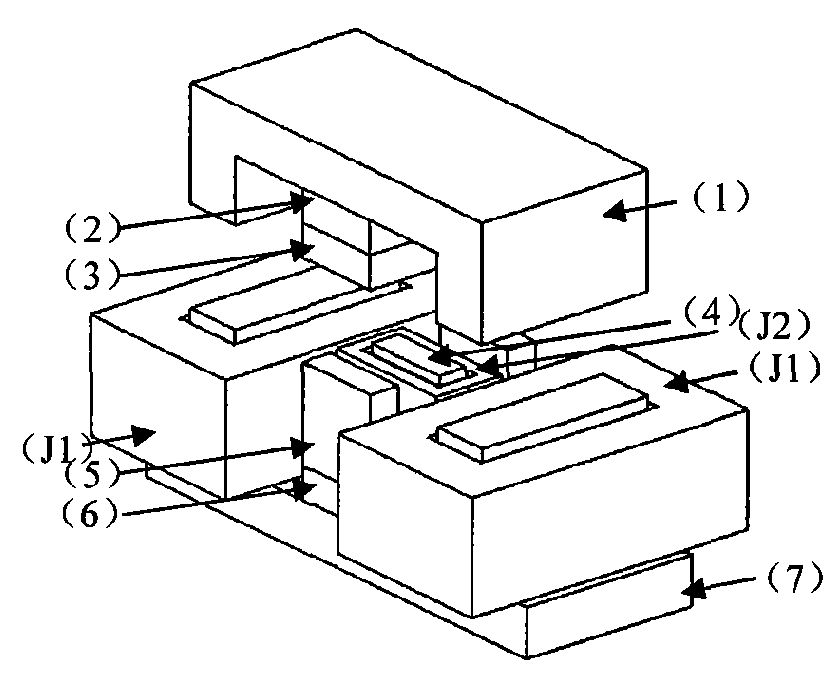

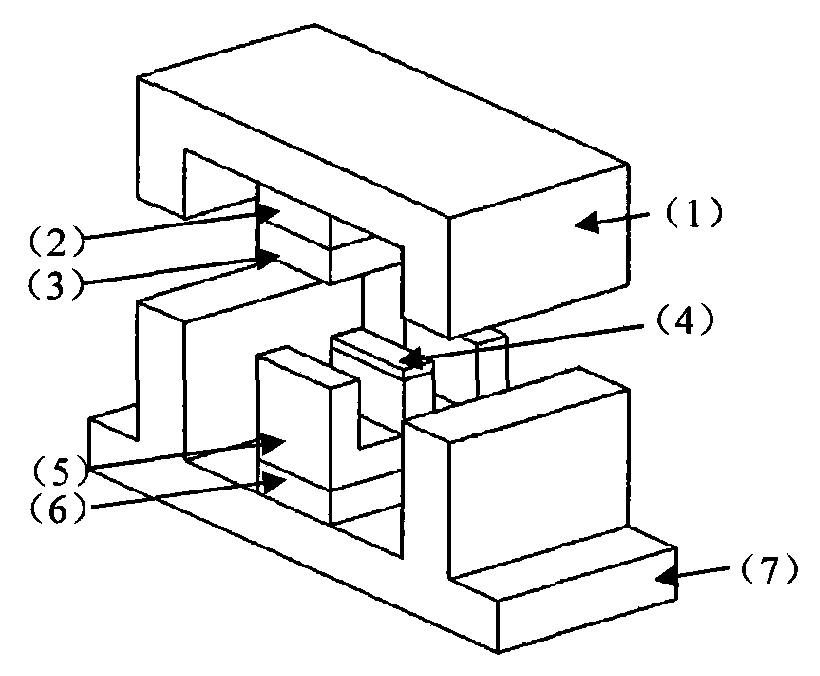

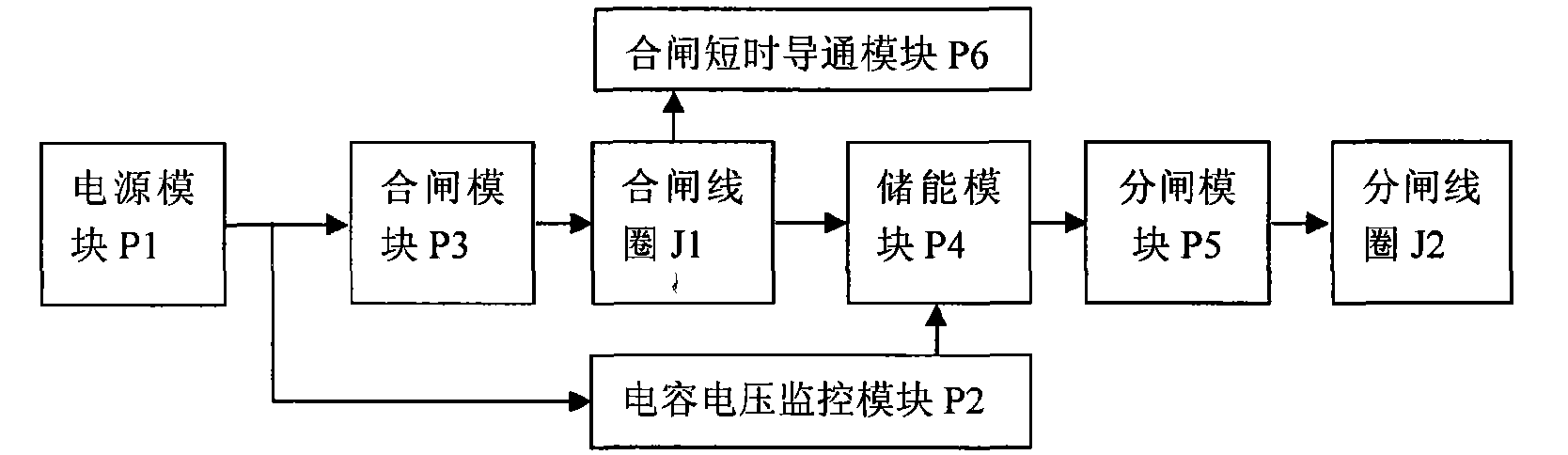

[0027] The separation magnetic circuit permanent magnet mechanism contactor and its control unit of the present invention mainly include electromagnetic magnetic circuit moving iron core, moving iron core low magnetic permeability separator, permanent magnetic circuit moving iron core, permanent magnet, opening coil, closing Coil, permanent magnetic circuit static iron core, static iron core low magnetic permeability partition and electromagnetic magnetic circuit static core; the moving core part includes electromagnetic magnetic circuit moving core, moving iron core low magnetic permeability partition and permanent magnet magnetic circuit moving iron core, static core Parts include permanent magnets, permanent magnetic circuit static cores, static core low magnetic permeability partitions and electromagnetic magnetic circuit static cores, coils include opening coils and closing coils; electromagnetic magnetic circuit moving cores, permanent magnetic circuit moving cores, perman...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com