A self-supplied magnetic current damper

A magneto-rheological damper and variable damper technology, applied in vibration suppression adjustment, non-rotational vibration suppression, etc., can solve problems such as broken wires, low energy conversion efficiency, and oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

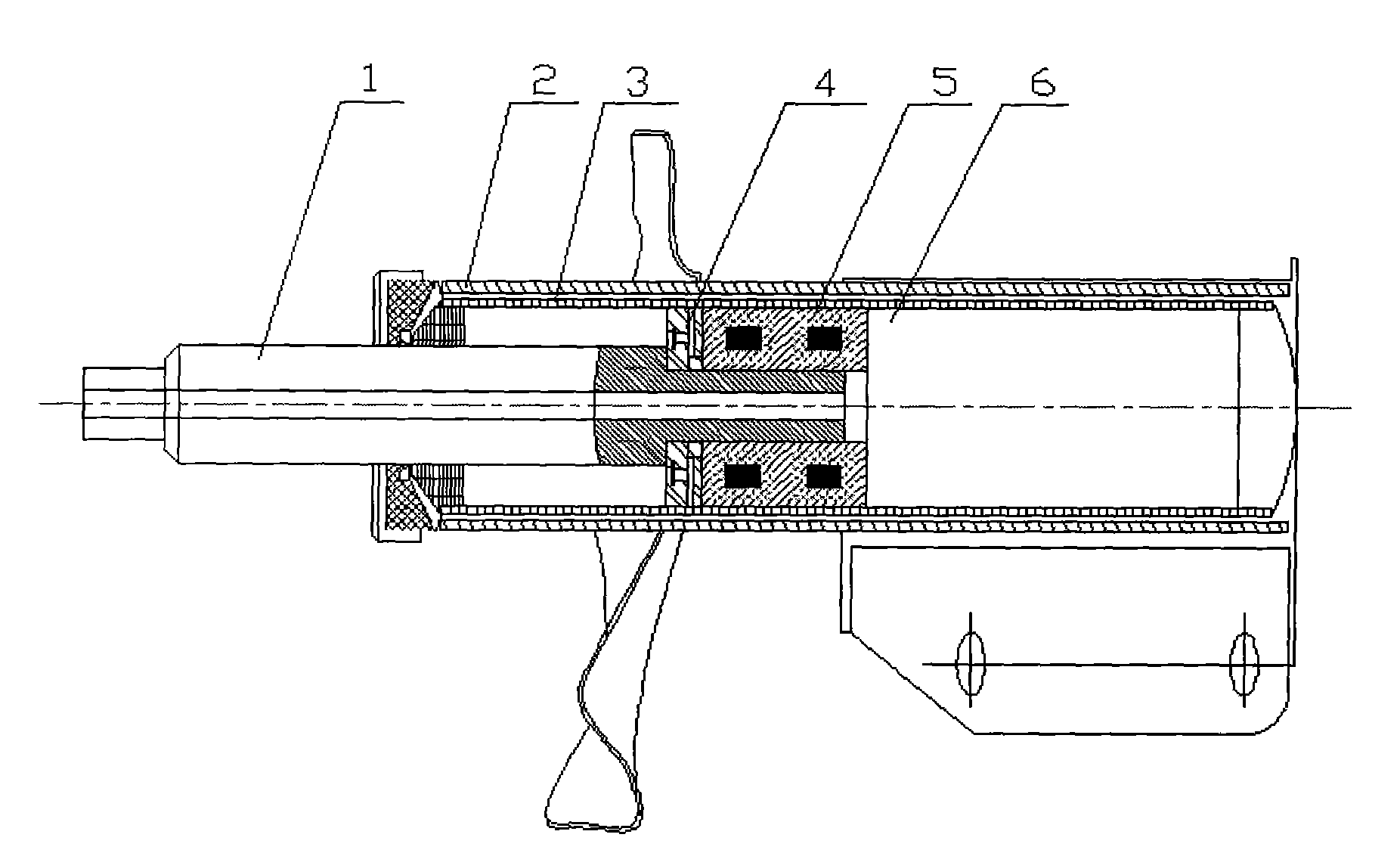

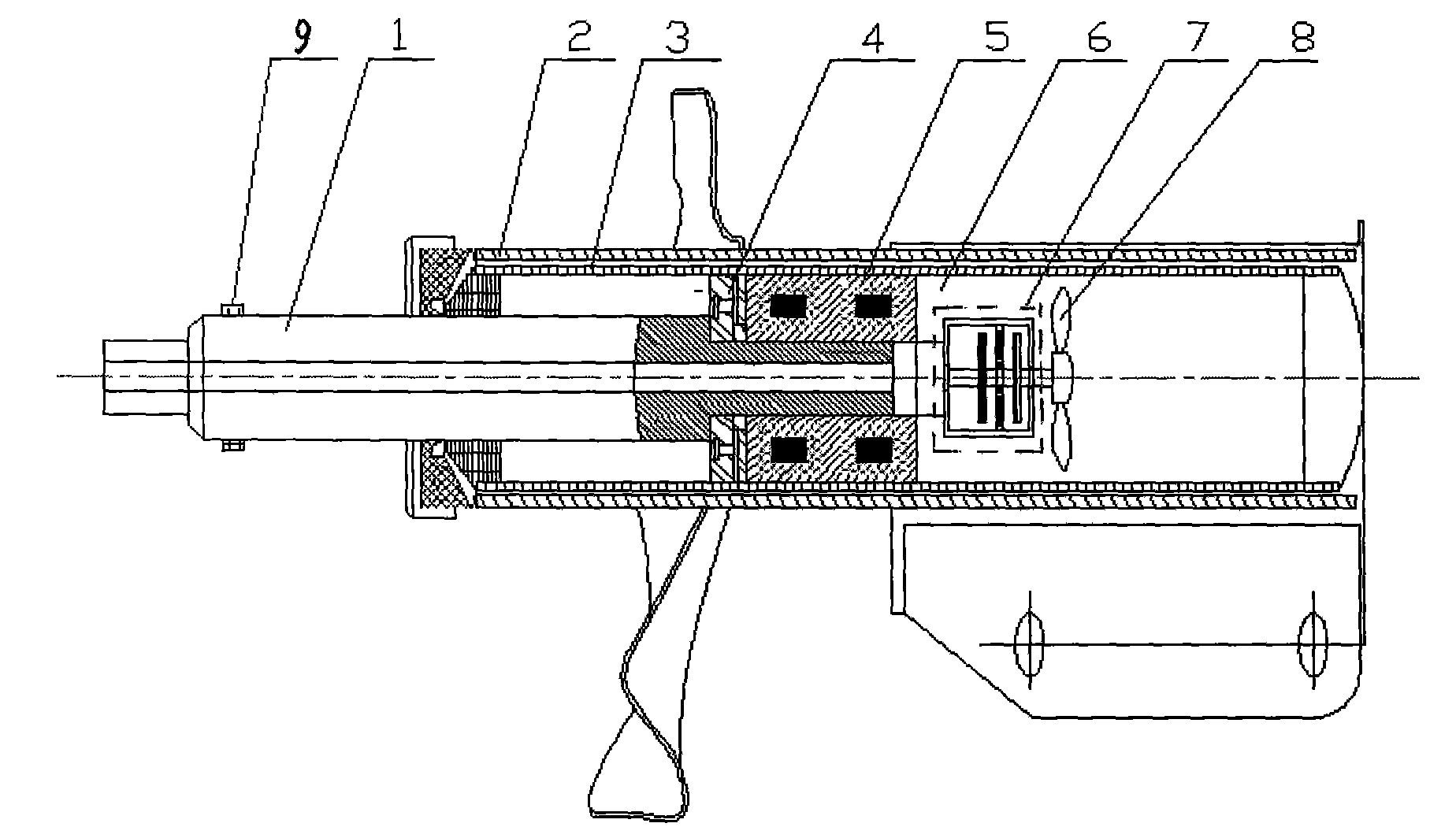

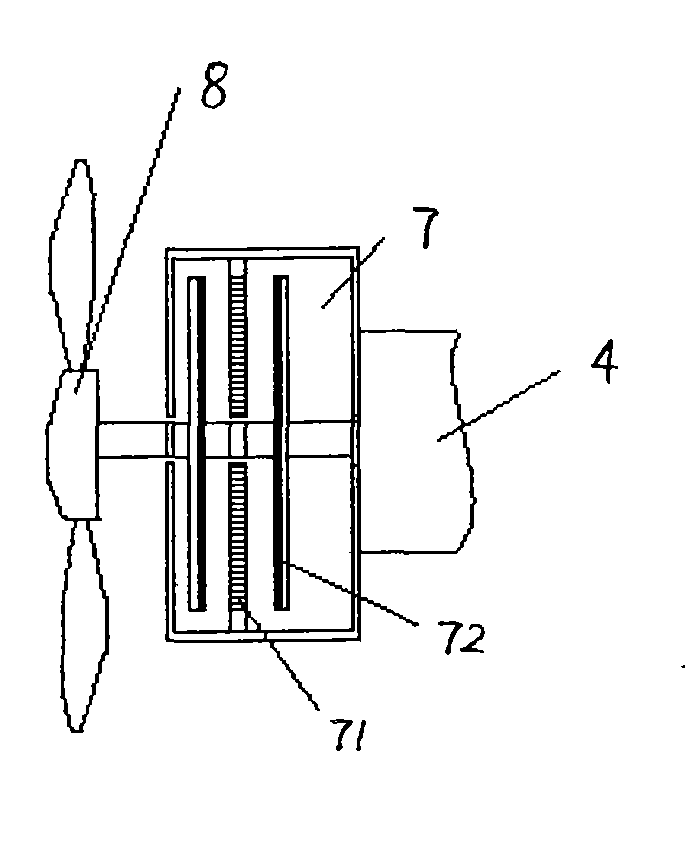

[0019] see figure 2 , The self-supplied electromagnetic rheological damper is composed of a magnetorheological damper and a vibration energy harvester, which can realize the self-supply of the working power of the magnetorheological damper. The vibration energy harvester adopts a multi-blade disc electromagnetic structure, see Figure 3A with Figure 3B , the vibration energy harvester is composed of multiple impellers 8 and disc-shaped magnetoelectric transducers 7, and is installed at the bottom of the piston 4 of the magnetorheological damper. Other structures of the magnetorheological damper are the same as figure 1 Basically be the same, 9 is the limiting device that increases. The structure of the rotor 72 and the stator 71 of the disc magnetoelectric transducer 7 is shown in Figure 4 , the permanent magnet material selects rare earth permanent magnets with high magnetic energy product and high coercive force, such as Nd-Fe-B rare earth permanent magnets (the maximu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com