Warping mechanism used for small sample loom

A small-scale loom and yarn technology, which is applied to warping machines, textiles, papermaking, and other manufacturing equipment/tools, can solve the problems of small space for yarn loading, interrupted yarn winding, and inconvenience, and achieve easy production and installation, increased warping length, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

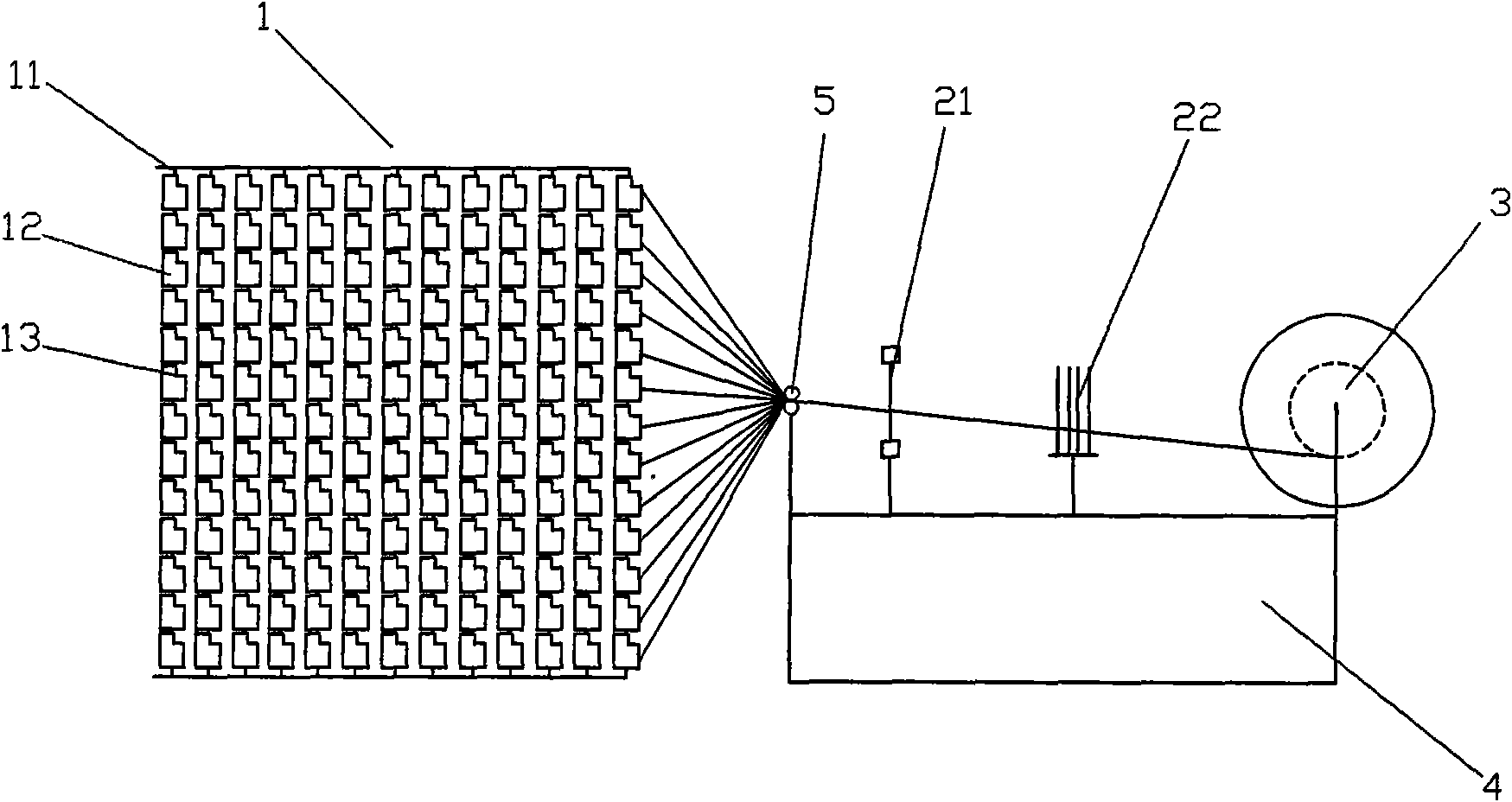

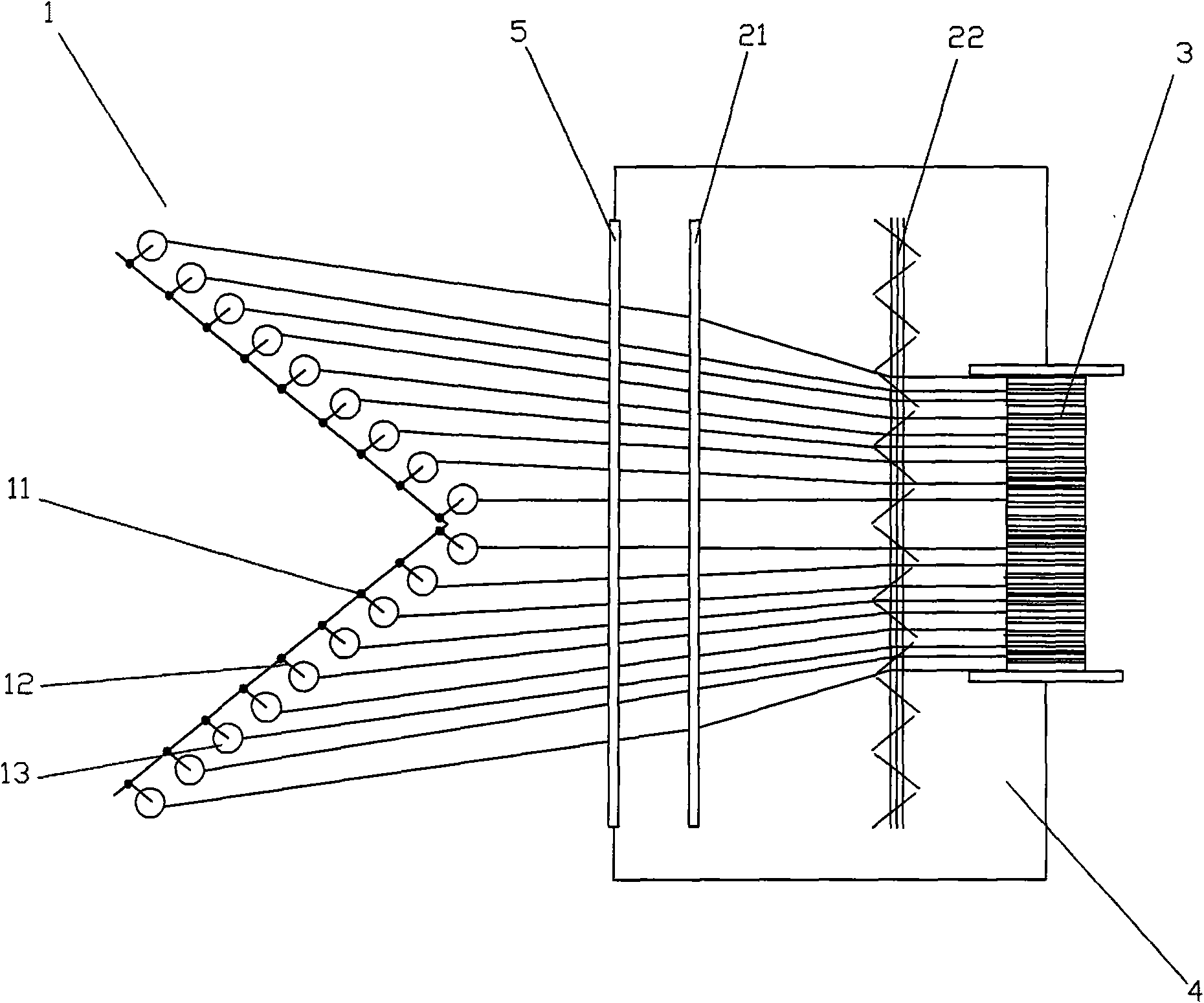

[0014] refer to figure 1 , a warping mechanism for a sample loom, comprising a yarn creel 1 for raking yarn, and the creel 1 is sequentially distributed with a yarn guide rod 5, a split reed 21, a telescopic reed 22 and Winding device 3, said creel 1 is provided with several yarn supports 11 arranged together, and a support 12 that rotates around the yarn support 11 is set on the yarn support 11, and the support 12 is set on Yarn reel 13 is arranged. The support 12 of the present invention can rotate around the yarn support 11, and is easy to adjust to a suitable angle to perform end-breaking or yarn-changing treatment on the yarn.

[0015] As a preferred mode, the yarn winding drum 13 is a shuttle box, and the yarn winding can be carried out by means of a sewing machine by using the shuttle box, so that the yarn winding is convenient.

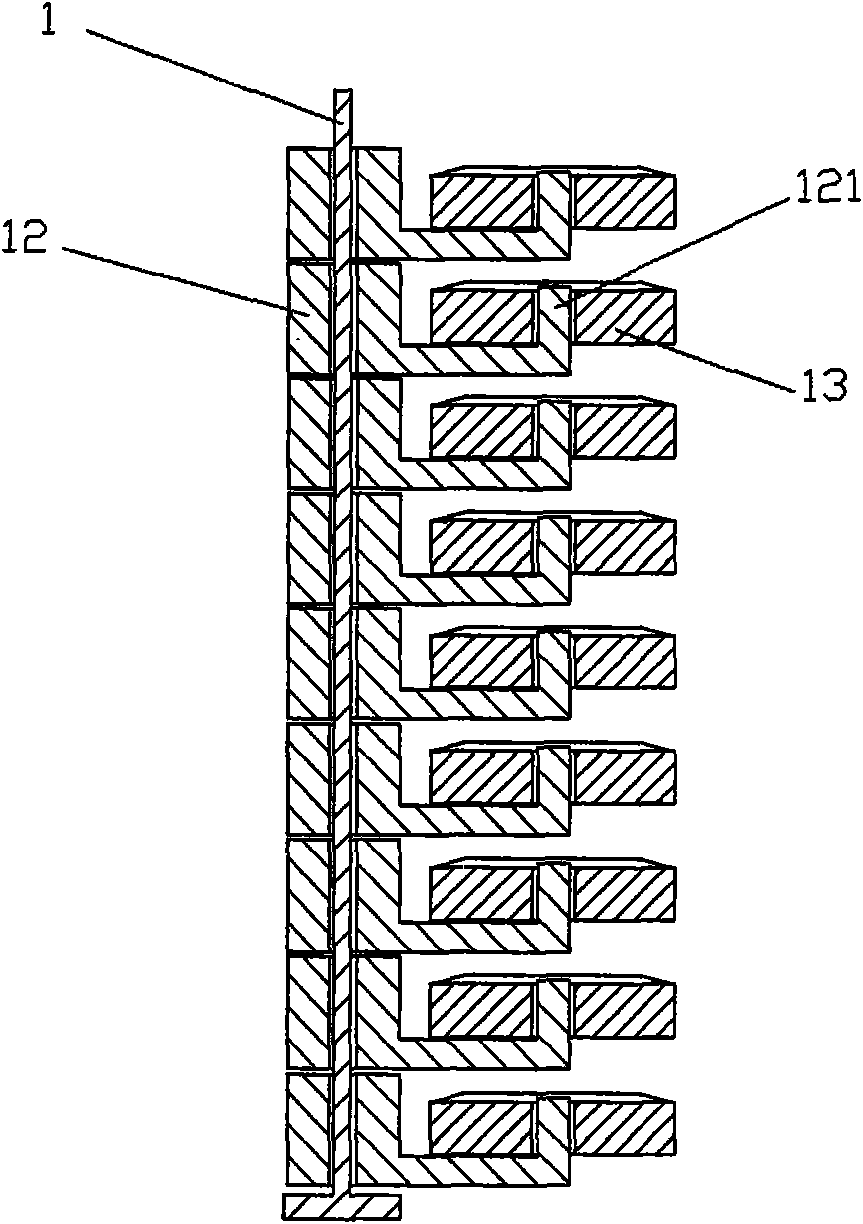

[0016] refer to figure 2 , in order to facilitate the installation of the winding bobbin 13, the winding bobbin 13 of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com