Passive yarn cutter

A shredder, passive technology, used in the transportation of filamentous materials, textiles and papermaking, thin material processing, etc., can solve the problems of high cost, uncapable tow, complex structure, etc., to achieve simple structure and product quality. Stable and high success rate of wire breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

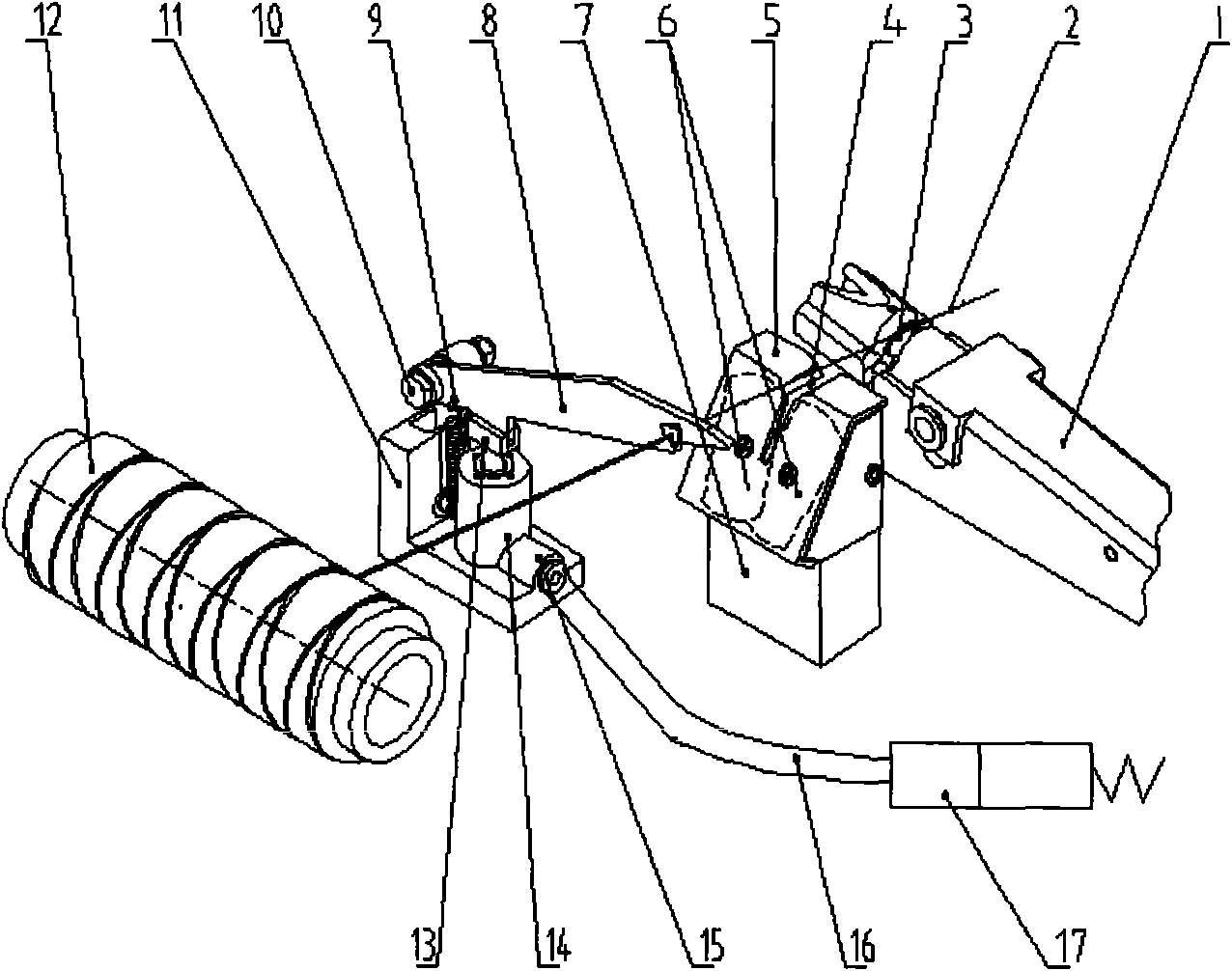

[0012] As shown in the figure, a passive shredder of the present invention includes a knife rest 7, two shred blades 6, a safety knife cover 5 and a wire catcher; The cross is obliquely installed on the knife rest 7, and forms the wire guide groove 4 with the notches on the knife rest 7 and the safety knife cover 5. In order to ensure that the silk catcher can catch the tow 2 smoothly, the silk catcher adopts pneumatic control.

[0013] The wire catcher comprises a cylinder base 11, a cylinder 14, a screw rod 8 and a spring 9; wherein the cylinder 14 is installed on the cylinder base 11, and the wire catcher 8 is installed on the upwardly extending boss of the cylinder base 11 with a support shaft 10, catching The lower edge of the front end of the screw rod 8 is provided with a slot for catching wire, and the boss on the lower edge of the rear end is placed in the screw catching rod shelf 13 which is integrated with the piston 18, so that the screw rod 8 follows the up and dow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com