Transport system and producing method of sub-vacuum duct

A technology for vacuum pipelines and transportation systems, applied in tunnel systems, roads, rails, etc., can solve the problems of large vacuum extraction projects, inconvenient passage of passengers, and poor passage sealing, achieving good sealing effect and eliminating the need for entry and exit. channel, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

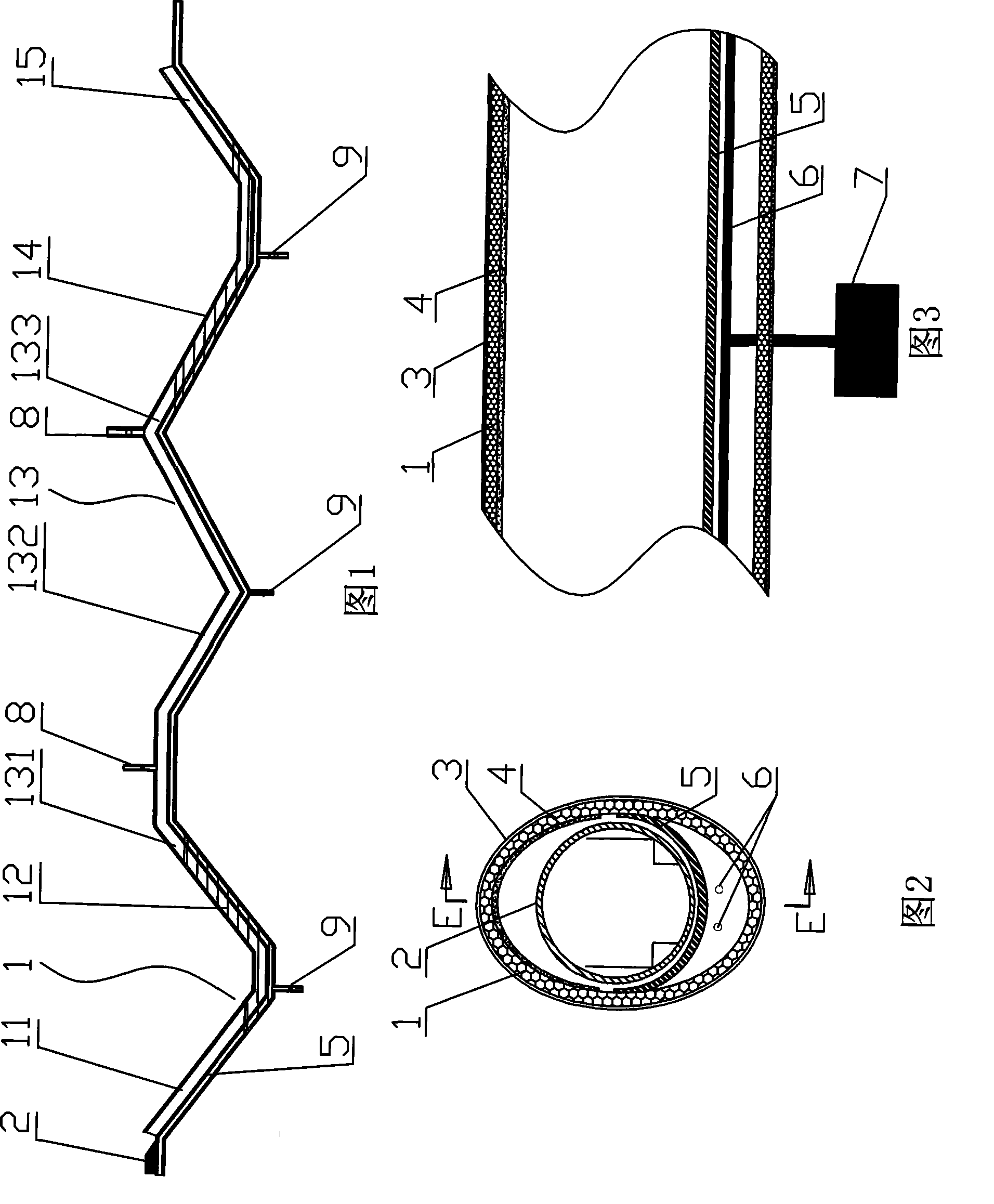

[0044] Example 1: Magnetic levitation sub-vacuum pipeline transportation system

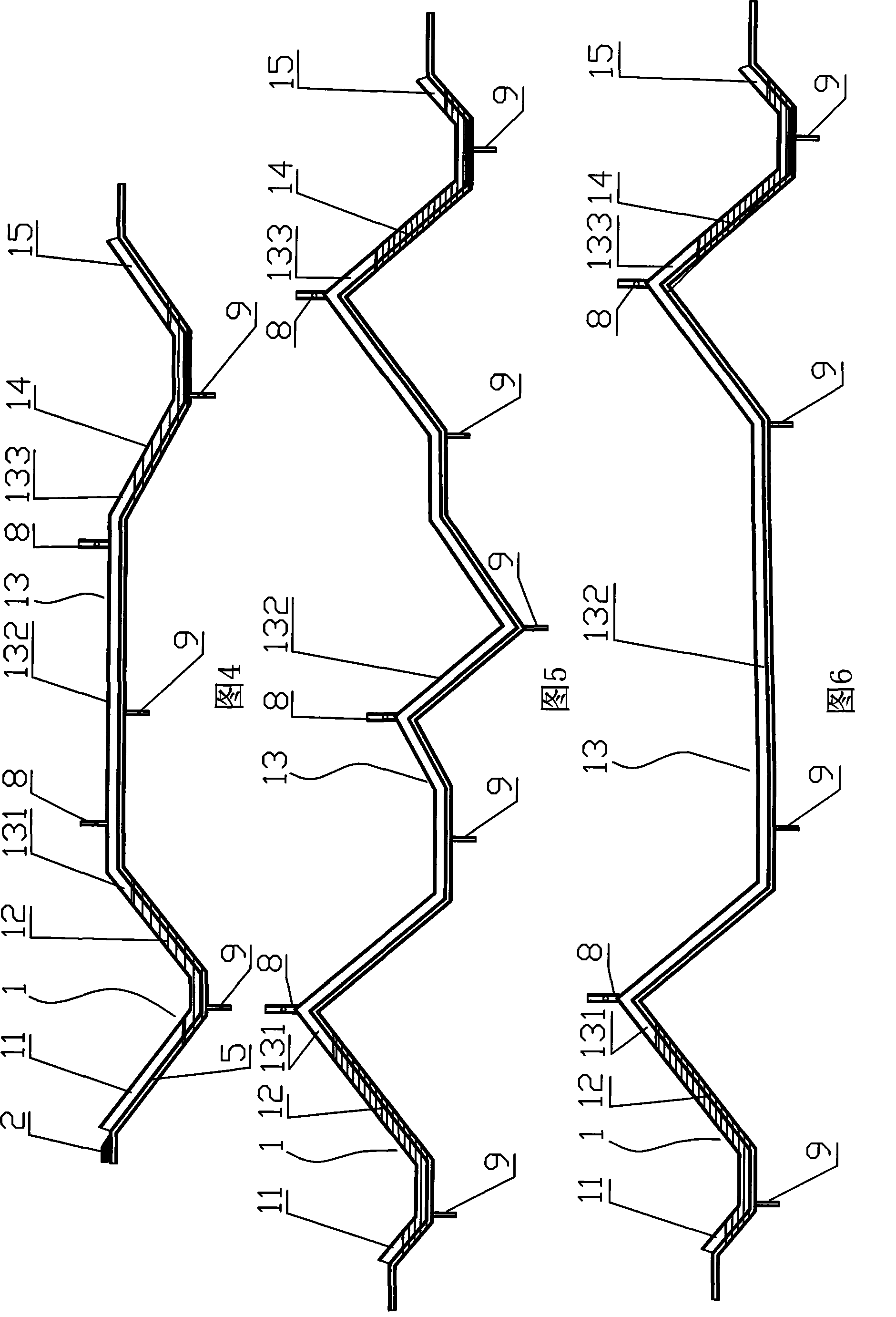

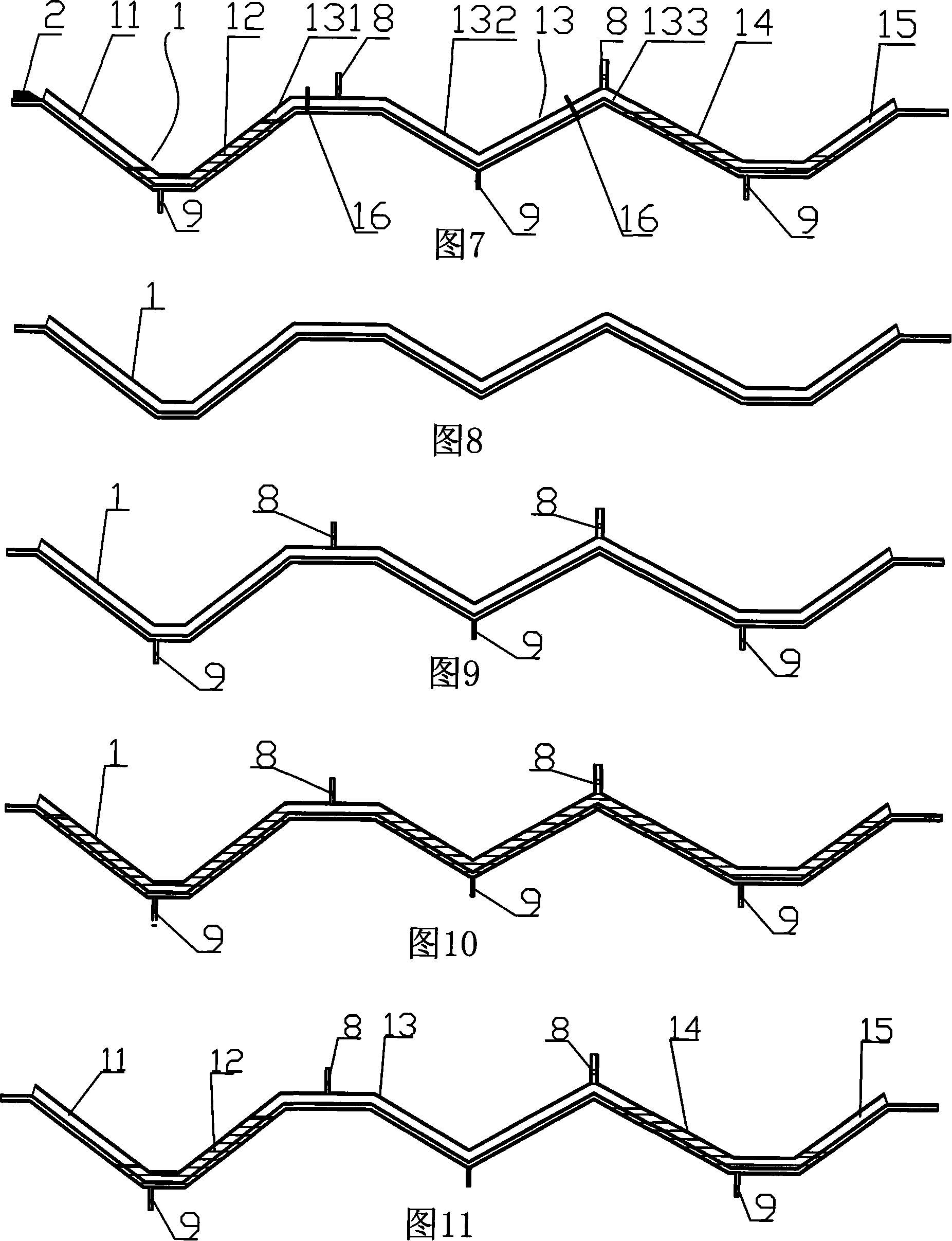

[0045] As shown in Figures 1 to 3, a magnetically levitated sub-vacuum pipeline transportation system includes a sub-vacuum pipeline 1 and a closed magnetic levitation train 2, a life support system is installed in the train body 2, and the sub-vacuum Pipeline 1 is composed of five parts, which are successively connected, the inlet atmospheric pressure downhill section 11, the inlet water sealing section 12, the sub-vacuum section 13, the outlet water sealing section 14 and the outlet atmospheric pressure uphill section 15 (see Figure 1) , the sub-vacuum section 13 is divided into a sub-vacuum ascending section 131, a sub-vacuum middle section 132 and a sub-vacuum descending section 133, wherein the sub-vacuum middle section 132 is a curve shape undulating with the terrain; 11 is connected to the sub-vacuum ascending section 131 through the inlet water-sealed section 12, and the outlet atmospheri...

Embodiment 2

[0055] Embodiment 2: A magnetic levitation sub-vacuum pipeline transportation system with valves in the pipeline

[0056] A magnetic levitation type sub-vacuum pipeline transportation system with valves in the pipeline (see Fig. 6), its basic structure and the running process of the train in the sub-vacuum pipeline are all the same as in Embodiment 1, wherein its basic structure includes sub-vacuum pipeline 1 and Airtight maglev train 2, a life support system is installed in the train body 2, and the sub-vacuum pipeline 1 is composed of an inlet atmospheric normal pressure downhill section 11, an inlet water sealing section 12, and a sub-vacuum section connected in sequence. 13. The outlet water sealing section 14 and the outlet atmospheric atmospheric pressure uphill section 15 are composed of five parts. The sub-vacuum section 13 is divided into a sub-vacuum rising section 131, a sub-vacuum middle section 132 and a sub-vacuum descending section 133, wherein, The sub-vacuum m...

Embodiment 3

[0058] Example 3: Wheel-rail sub-vacuum pipeline transportation system

[0059] A wheel-rail type sub-vacuum pipeline transportation system, its basic structure and the running process of the train in the sub-vacuum pipeline are the same as in Embodiment 1, the difference is that the bottom of the sub-vacuum pipeline 1 is equipped with rails, and the bottom of the train 2 It is mounted on wheels and driven by conventional electrified train motors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com