Machine for washing rubber boots

A washing machine and rubber boots technology, which is applied in the cleaning of boots and shoes, cleaning equipment, household cleaning devices, etc., can solve the problems of troublesome cleaning, low cleaning efficiency, manual cleaning, etc., and achieve the effect of convenient use and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

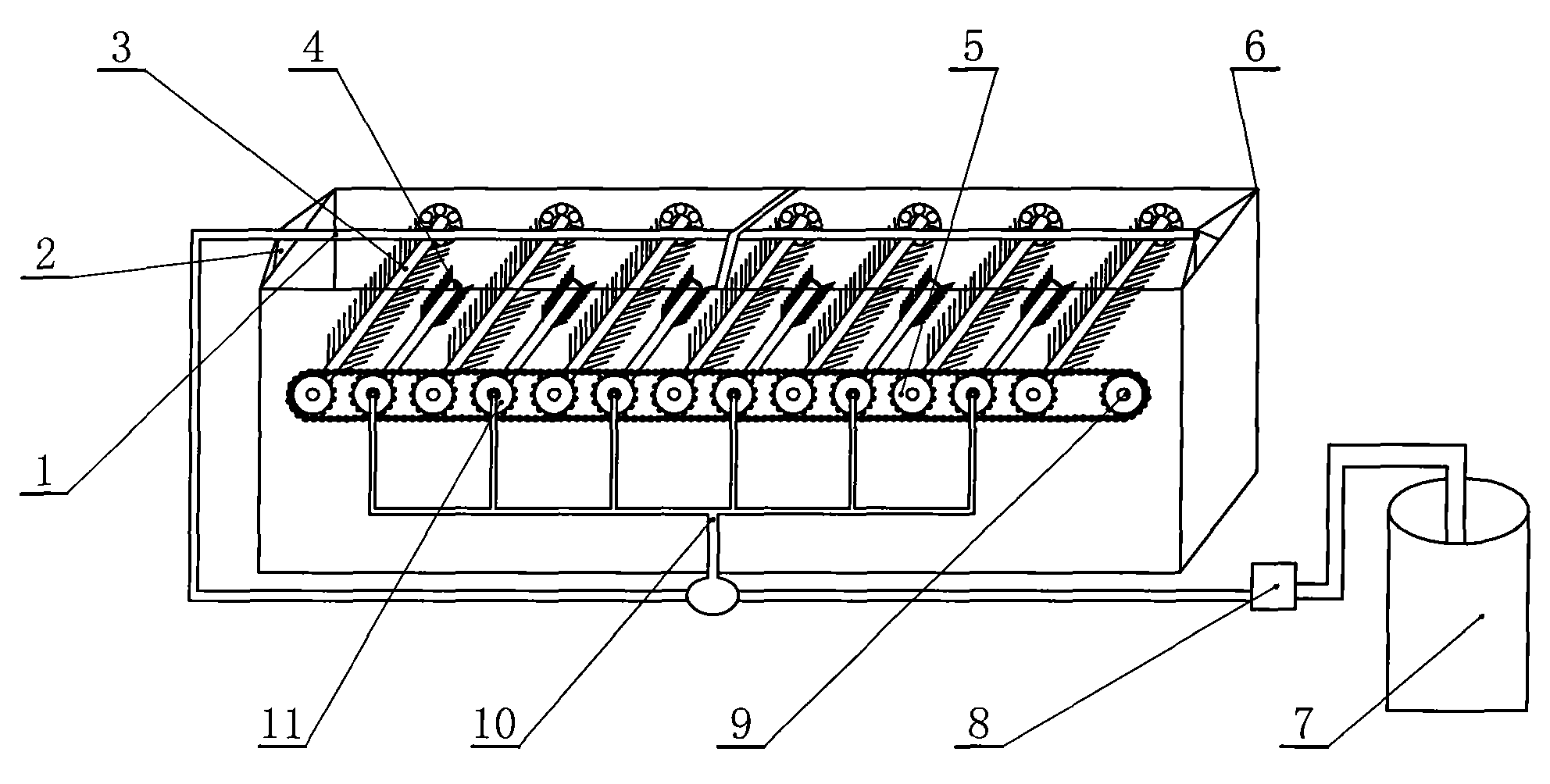

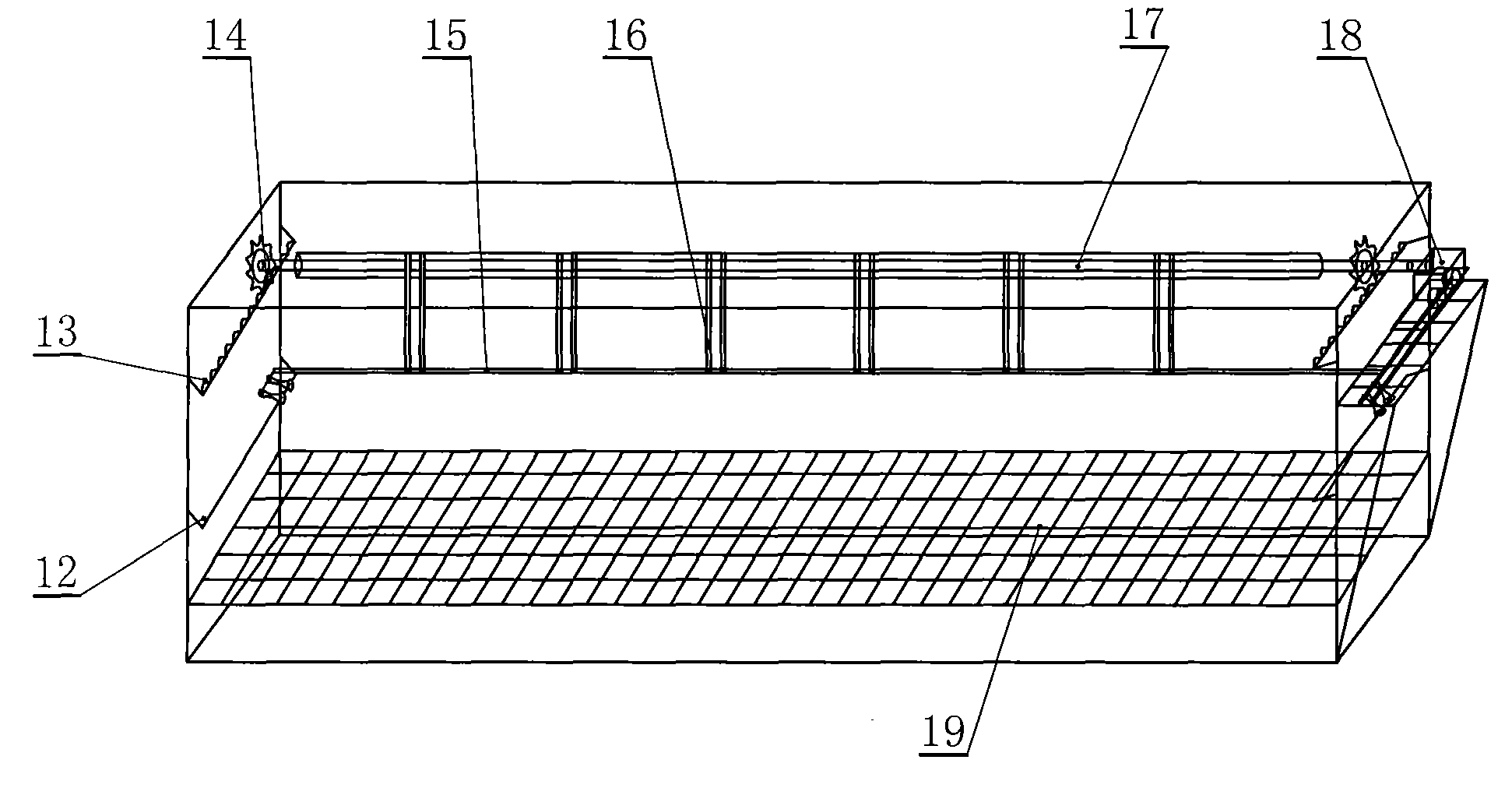

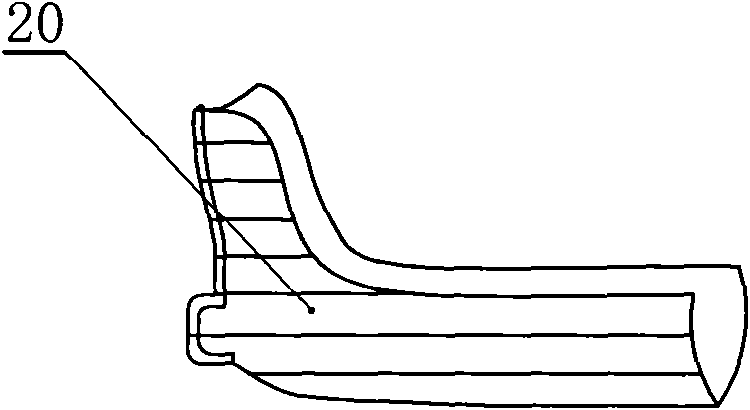

[0012] A rubber boot cleaning machine such as figure 1 , 2 , 3 and 4, including a brush shoe machine casing 6, characterized in that: brush gear 11 and motor driving wheel 9 are designed on the front and rear side walls of the brush shoe machine casing 6, and the brush gear 11 passes through The side water injector 21 is connected with a hair brush 4, and the hair brush 4 is located in the shoe brush machine casing 6. The side water injector 21 is connected with an infusion tube 10, and the side water injector 21 communicates with the infusion tube 10, and the infusion tube 10 passes through the The three links are respectively connected to the clean water pipe and the washing liquid bucket 7, the infusion pipe 10 is connected to the liquid supply pump 8, and the inner surface of the left and right side walls of the shoe brush machine casing 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com