Impeller-less powerful sludge pump

An impeller-free, powerful technology, applied in the direction of pumps, jet pumps, non-displacement pumps, etc., can solve the problems of poor jetting force of the sewage suction device, affecting the working efficiency of the sewage suction device, and unsatisfactory rotating wind power. Simple, low cost, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

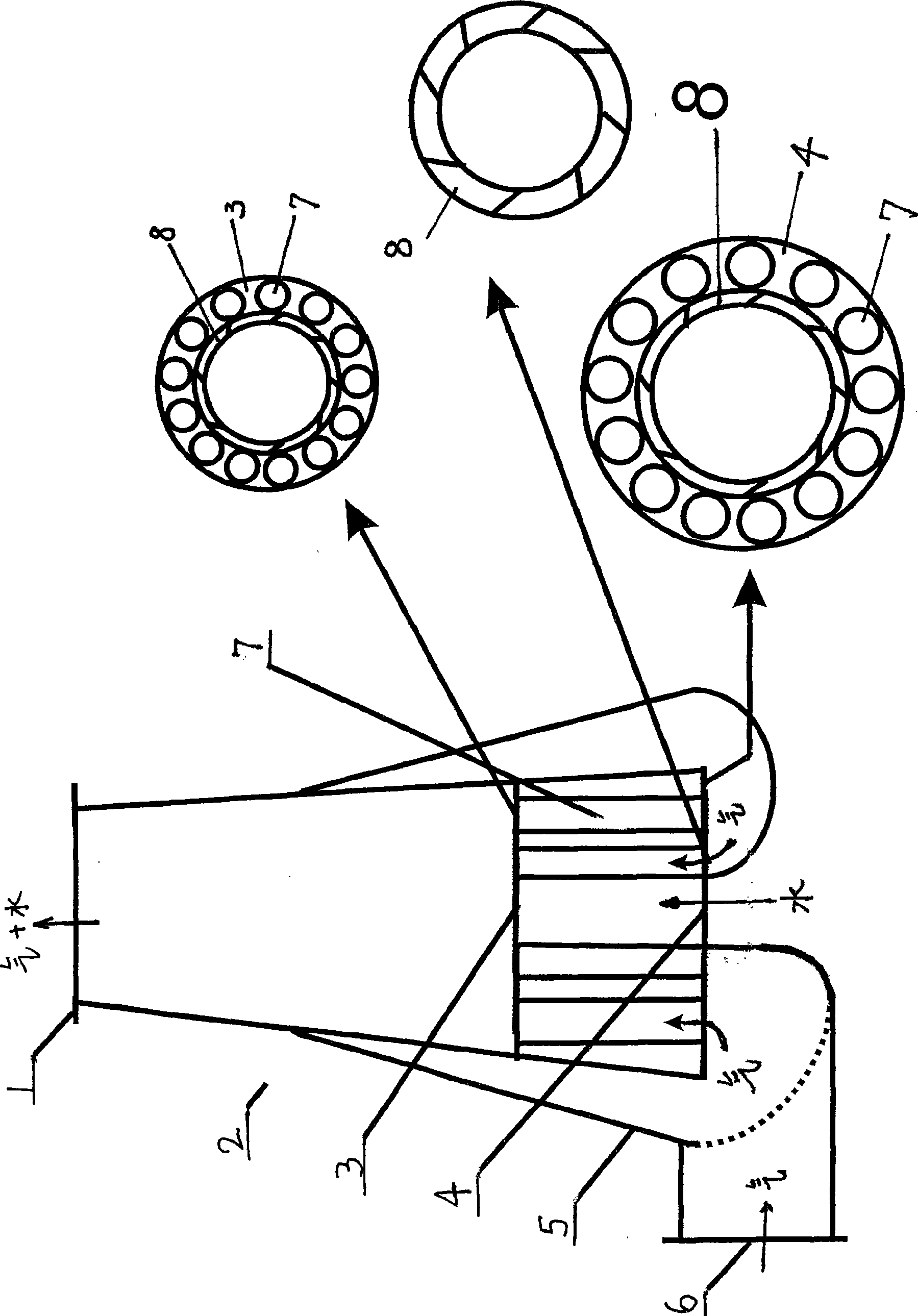

[0012] Referring to the accompanying drawings: the upper end of the conical sewage suction pump body 2 with a length of 500mm, an inner diameter of the upper end of 160mm, and an inner diameter of the lower end of 260mm is welded with an air outlet flange 1, and the lower part of the sewage suction pump body 2 is provided with a ring type The upper fixing plate 3 and the lower fixing plate 4, wherein the diameter of the upper fixing plate is smaller than the diameter of the lower fixing plate, and the outer circumference of each fixing plate is provided with 13 through holes, and each through hole is welded with a small upper and lower Large tapered air duct 7; on the lower outer wall of the sewage suction pump body 2, a trumpet-shaped air distribution package 5 is welded, and the air inlets of the 13 air ducts on the lower fixing plate 4 are all opened in the air distribution package 5 In the inner chamber, the air outlets of the 13 air pipes on the upper fixing plate 3 are al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com