Method for treating and recycling waste paper making wastewater

A waste paper papermaking and wastewater treatment technology, which is applied in the directions of biological water/sewage treatment, adsorption water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of long biochemical residence time, save floor space, improve Recycling rate, effect of reducing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

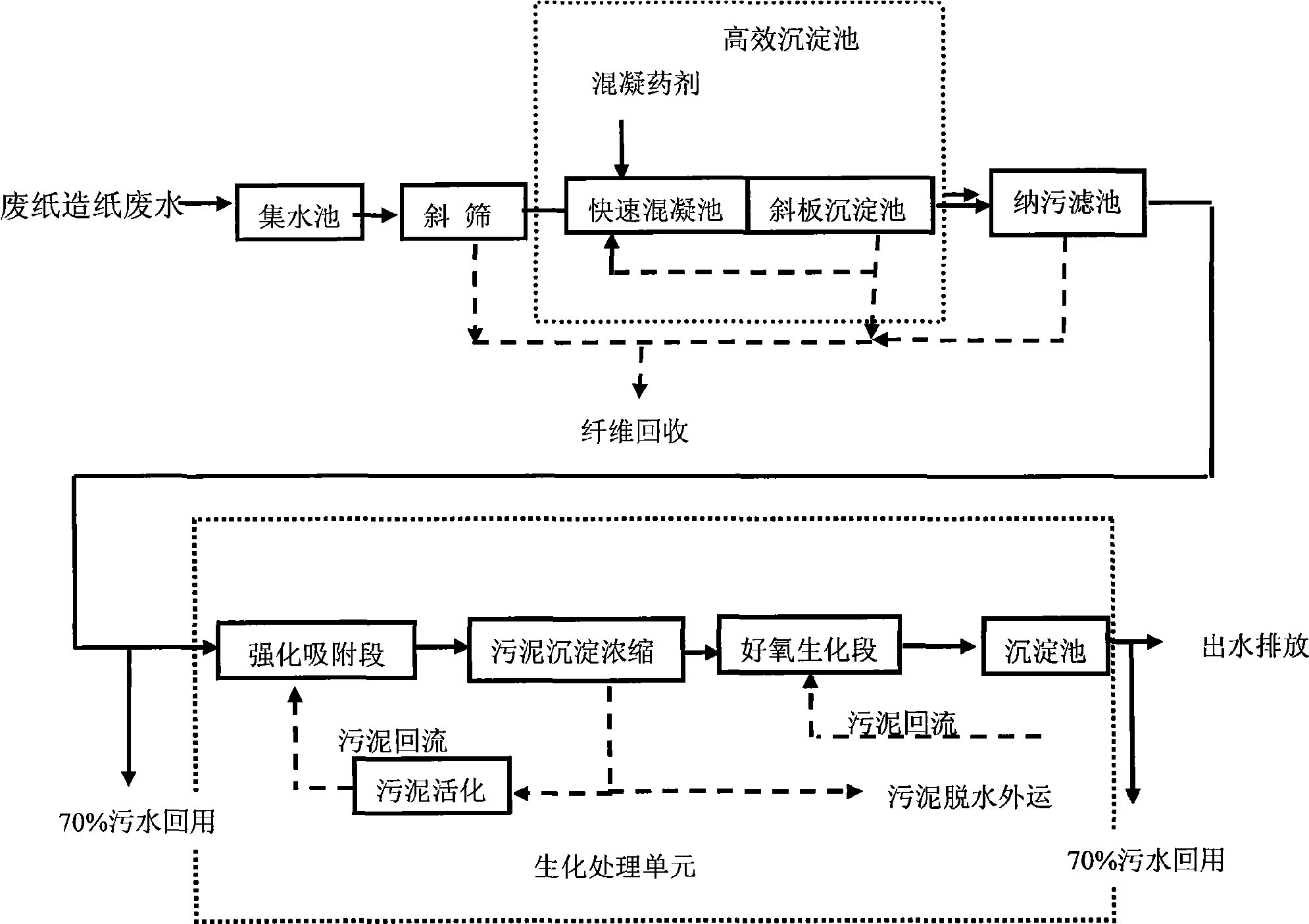

[0025] COD cr 1120mg / L, BOD 5 Waste paper and papermaking wastewater with a concentration of 340mg / L and a SS of 960mg / L enters the physical and chemical treatment unit, and the mesh holes of the inclined sieve are used to intercept the coarse fiber and recycle the fiber at the same time. The mesh size is 120 mesh; the effluent of the inclined sieve enters the high-efficiency sedimentation tank , add the coagulant polyaluminum chloride, the dosage of the coagulant is 10mg / L, and remove most of the suspended solids through coagulation and inclined plate sedimentation tank, in which the coagulation time is 9min, and the surface load of the inclined plate sedimentation tank 18m / h; the effluent from the high-efficiency sedimentation tank enters the sewage filter, which mainly relies on the filter material for filtration. The effluent of the nano-pollution filter enters the enhanced adsorption section of the biochemical treatment unit, and uses high-concentration sludge to absorb ...

Embodiment 2

[0027] COD cr 3458mg / L, BOD 5 680mg / L, SS 3000mg / L waste paper papermaking wastewater enters the physical and chemical treatment unit, uses the mesh holes of the inclined screen to intercept the coarse fiber, and recycles the fiber at the same time, the mesh size is 100 mesh; the water from the inclined screen enters the high-efficiency sedimentation tank , add the coagulant polyaluminum chloride, the dosage of the coagulant is 25mg / L, remove most of the suspended solids through coagulation and inclined plate sedimentation tank, the coagulation time is 12min, and the surface load of the inclined plate sedimentation tank 15m / h; the effluent from the high-efficiency sedimentation tank enters the sewage filter, which mainly relies on the filter material for filtration. The effluent of the nano-pollution filter enters the enhanced adsorption section of the biochemical treatment unit, and uses high-concentration sludge to absorb and absorb some pollutants. The hydraulic retention ...

Embodiment 3

[0029] COD cr 2373mg / L, BOD 5 540mg / L, SS 1800mg / L waste paper papermaking wastewater enters the physical and chemical treatment unit, uses the mesh holes of the inclined screen to intercept the coarse fiber, and recycles the fiber at the same time, the mesh size is 110 mesh; the water from the inclined screen enters the high-efficiency sedimentation tank , adding coagulant polyaluminum chloride, the dosage of coagulant is 13mg / L, most of the suspended solids are removed through coagulation and inclined plate sedimentation tank, the coagulation time is 12min, and the surface load of inclined plate sedimentation tank 16m / h; the effluent from the high-efficiency sedimentation tank enters the sewage filter, which mainly relies on the filter material for filtration. The effluent of the nano-pollution filter enters the enhanced adsorption section of the biochemical treatment unit, and uses high-concentration sludge to absorb and absorb some pollutants. The hydraulic retention time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface load factor | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com