Simple mouth fastening type plastic film garbage bag

A garbage bag and plastic film technology, which is applied in the field of plastic film products, can solve the problems of excessive materials used, inconvenient use, increased materials used for making plastic film bags and manufacturing costs, etc., so as to reduce manufacturing costs, reduce materials used, use and The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

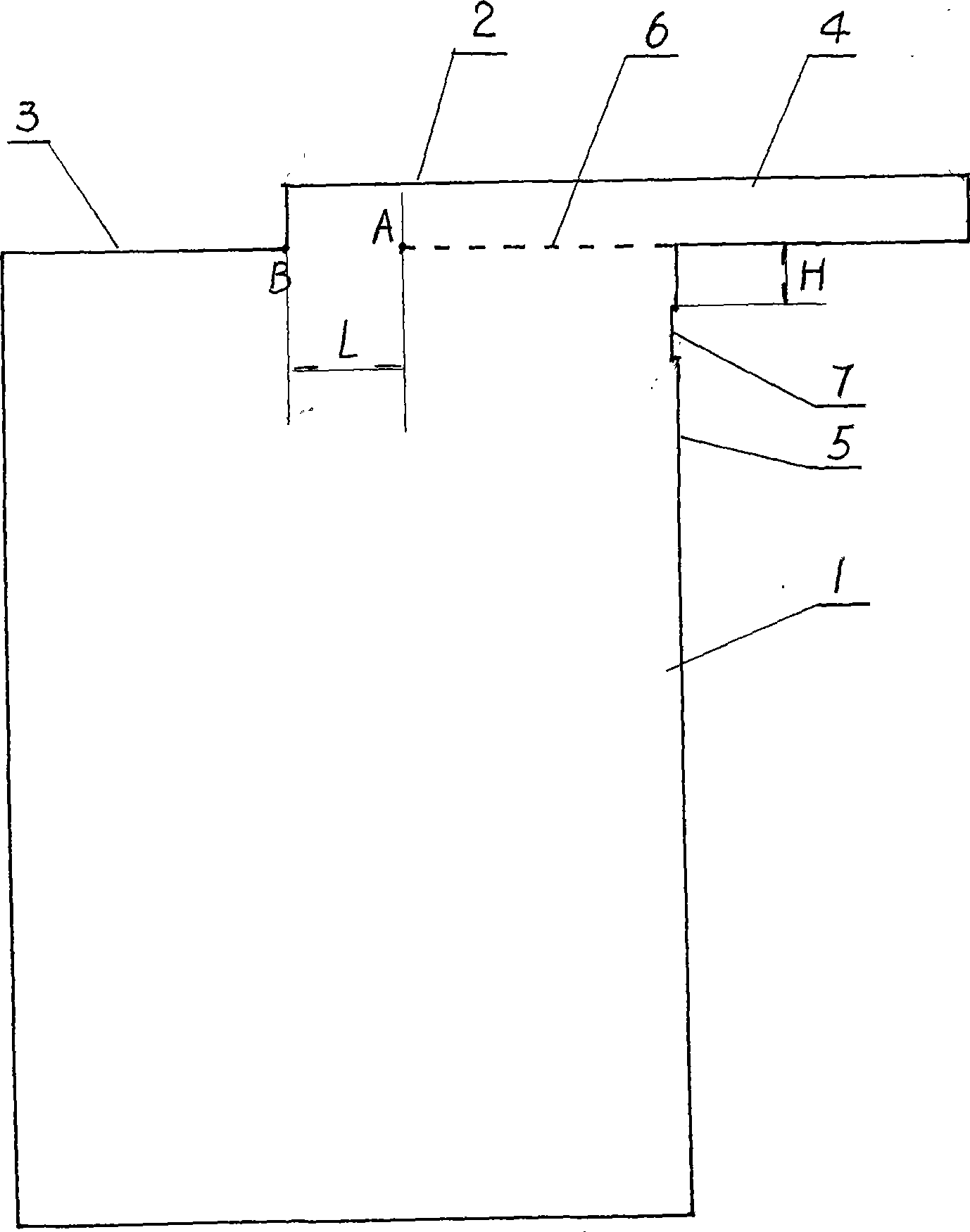

[0016] Example: from figure 1 It can be clearly seen that the simple tie-top plastic film garbage bag has a plastic film bag body 1 similar to ordinary plastic film garbage bags, and the left side of the mouth 2 of the film bag body 1 is provided with a band-shaped notch section 3 , the right side of the bag opening is provided with a strip-shaped stretching section 4 equal in length to the strip-shaped notch section 3; along the film bag body 1 on the lower edge of the strip-shaped stretching section 4, a linear point break mark 6 is provided, the There is an L=5cm non-point fracture region between the terminal A of the linear point fracture mark 6 and the end B of the band-shaped notch section 3 . The film bag body 1 is provided with a shuttle hole 7 for the belt-shaped extension section 4 to be worn on the right bag edge 5 of H=2cm apart from the straight-line point broken mark 6 below.

[0017] The usage method of the present invention is basically the same as that of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com