MCFB fuel gas purifying device capable of jointly removing various pollutants

A technology for flue gas purification and pollutants, which is applied in the direction of combined devices, chemical instruments and methods, and separation of dispersed particles. absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

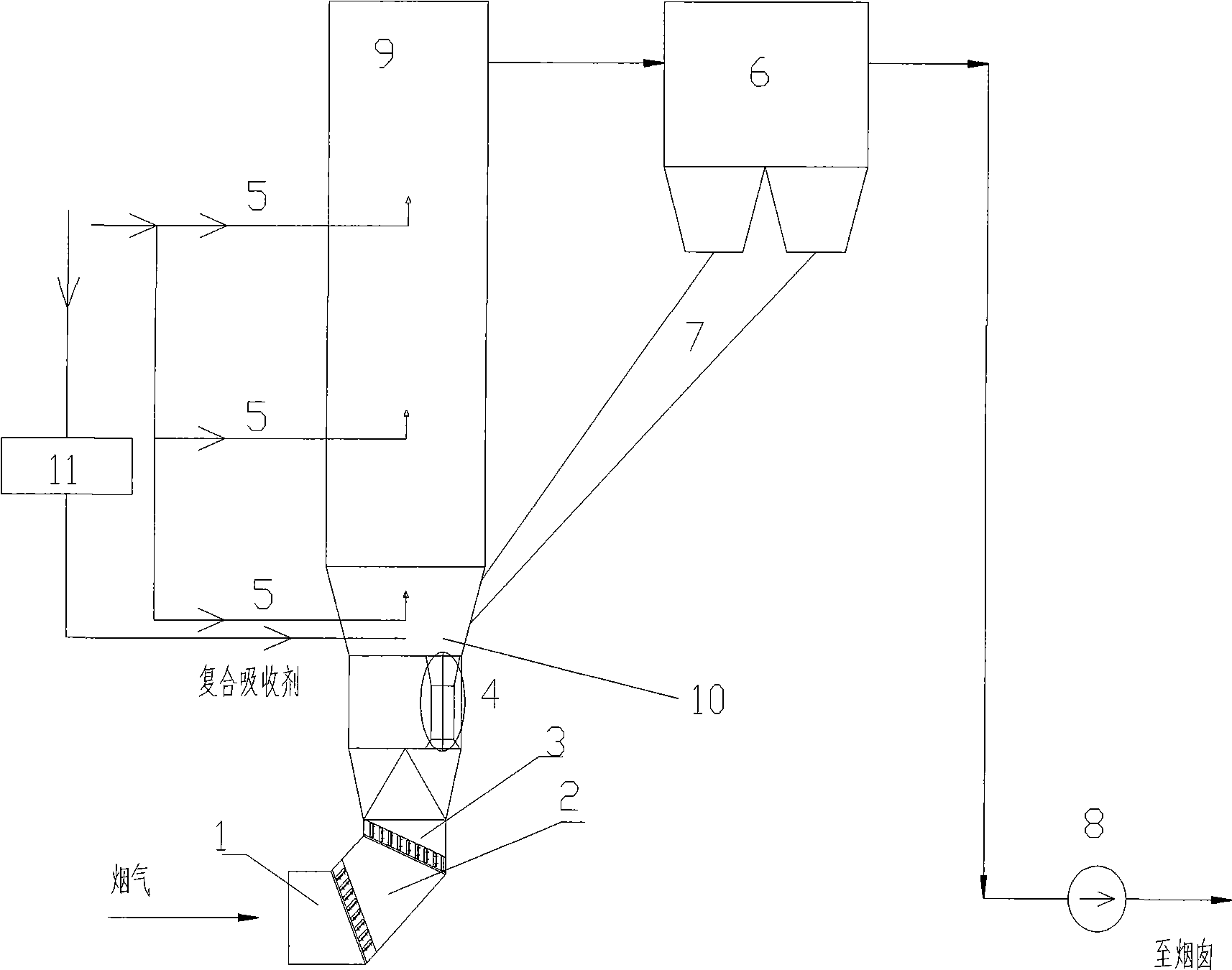

[0010] As shown in the attached figure, the MCFB flue gas purification device for synergistic removal of various pollutants is characterized in that it includes a connecting flue 1, a first-level flue gas uniform distribution device 2, a secondary flue gas uniform distribution device 3, and a Venturi device 4. Multi-stage humidification and activation device 5, dust collector 6, ash circulation device 7, induced draft fan 8, fluidized bed reactor 9, Venturi diffusion section 10, composite absorbent preparation device 11, lower end of fluidized bed reactor 9 It is connected with Venturi diffusion section 10, Venturi device 4, secondary flue gas uniform distribution device 3, primary flue gas uniform distribution device 2, and connecting flue 1 in sequence. The fan 8 is connected in turn, the bottom of the dust collector 6 is connected to the Venturi diffusion section 10 through the ash circulation device 7, and a multi-stage humidification and activation device 5 is installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com