Pressure-bearing assembling structure of fuel cell module

A fuel cell and pressure-bearing structure technology, which is applied in the direction of fuel cell grouping, fuel cells, battery pack components, etc., can solve the problems of affecting fuel cell conversion efficiency and high contact resistance, and achieve increased conductivity and permeability, and uniform The effect of bearing pressure and increasing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

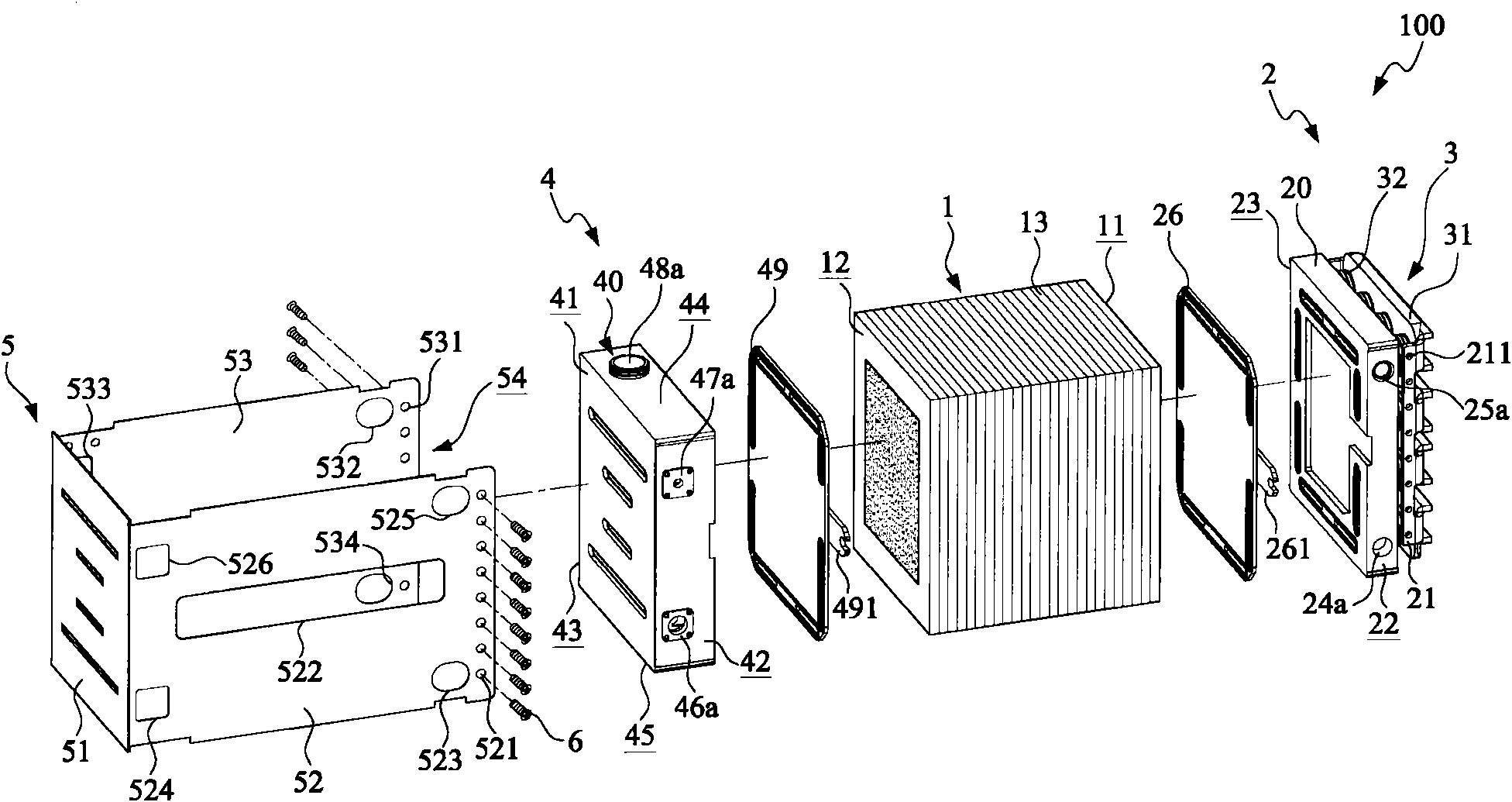

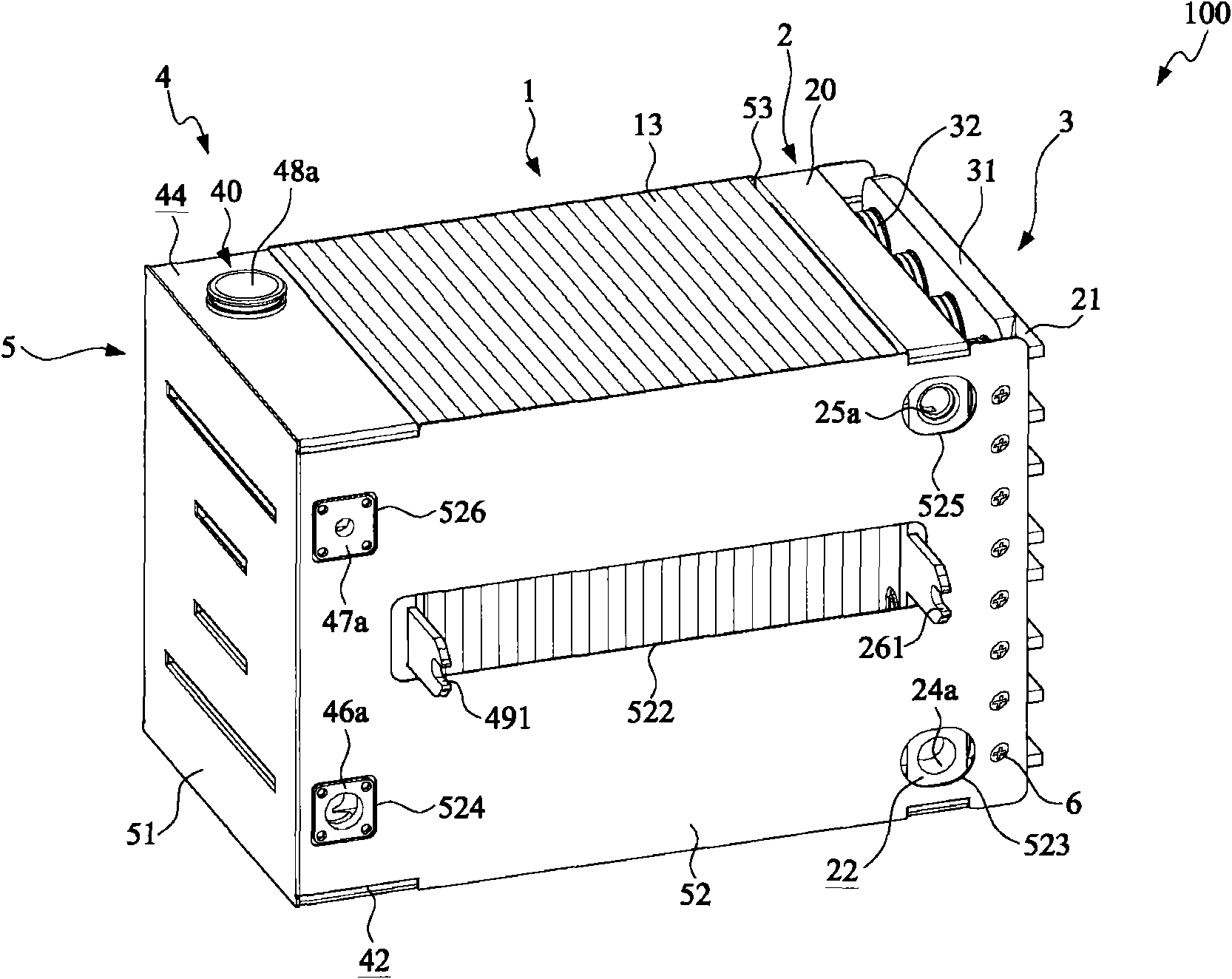

[0088] see figure 1 As shown, it is an exploded view showing the first embodiment of the present invention. The pressure-bearing assembly structure 100 of the fuel cell module of the present invention includes a fuel cell module 1 having a first pole side 11 and a second pole side 12 and composed of at least one battery cell 13 .

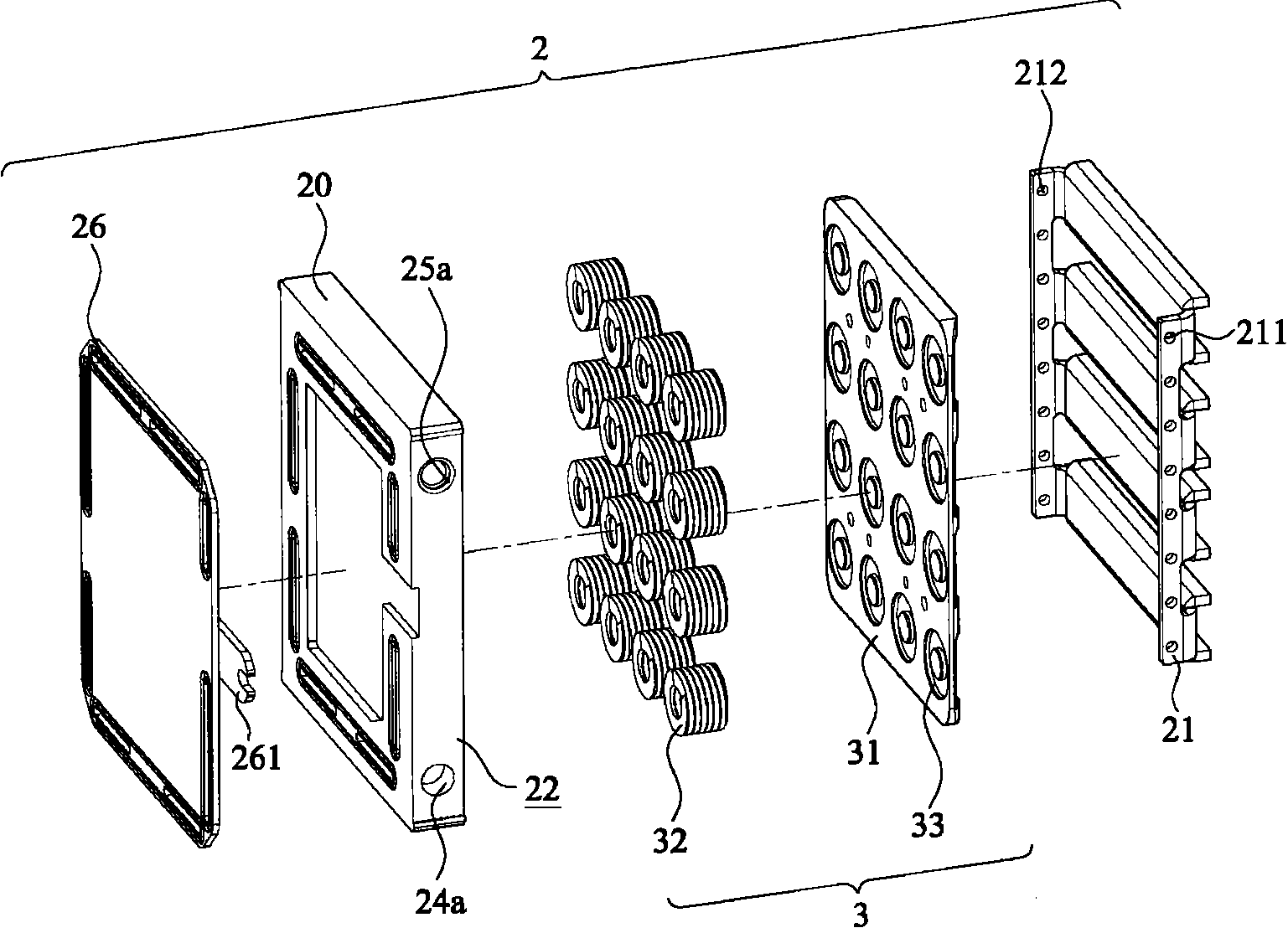

[0089] The first pole side 11 of the fuel cell module 1 is connected to a first pressure-bearing end plate 2 , and a first pole collector plate 26 is located therebetween. The first pressure-bearing end plate 2 has a first end plate 20 and a joint portion 21 , wherein two sides of the joint portion 21 are respectively provided with a row of holes 211 , 212 .

[0090] A pressure-bearing structure 3 (such as figure 2 As shown), it is composed of a pressure bearing plate 31 and a plurality of elastic components 32. The pressure-receiving plate 31 defines a plurality of pressure-receiving holes 33 corresponding to each elastic component 32 for nesti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com