Disturbance combustion-supporting device for waste incinerator

A garbage incinerator and garbage technology, which is applied in the direction of incinerator, combustion method, combustion type, etc., can solve the problems of insufficient garbage combustion, easy large slagging of garbage, etc., and achieve the effect of full garbage burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

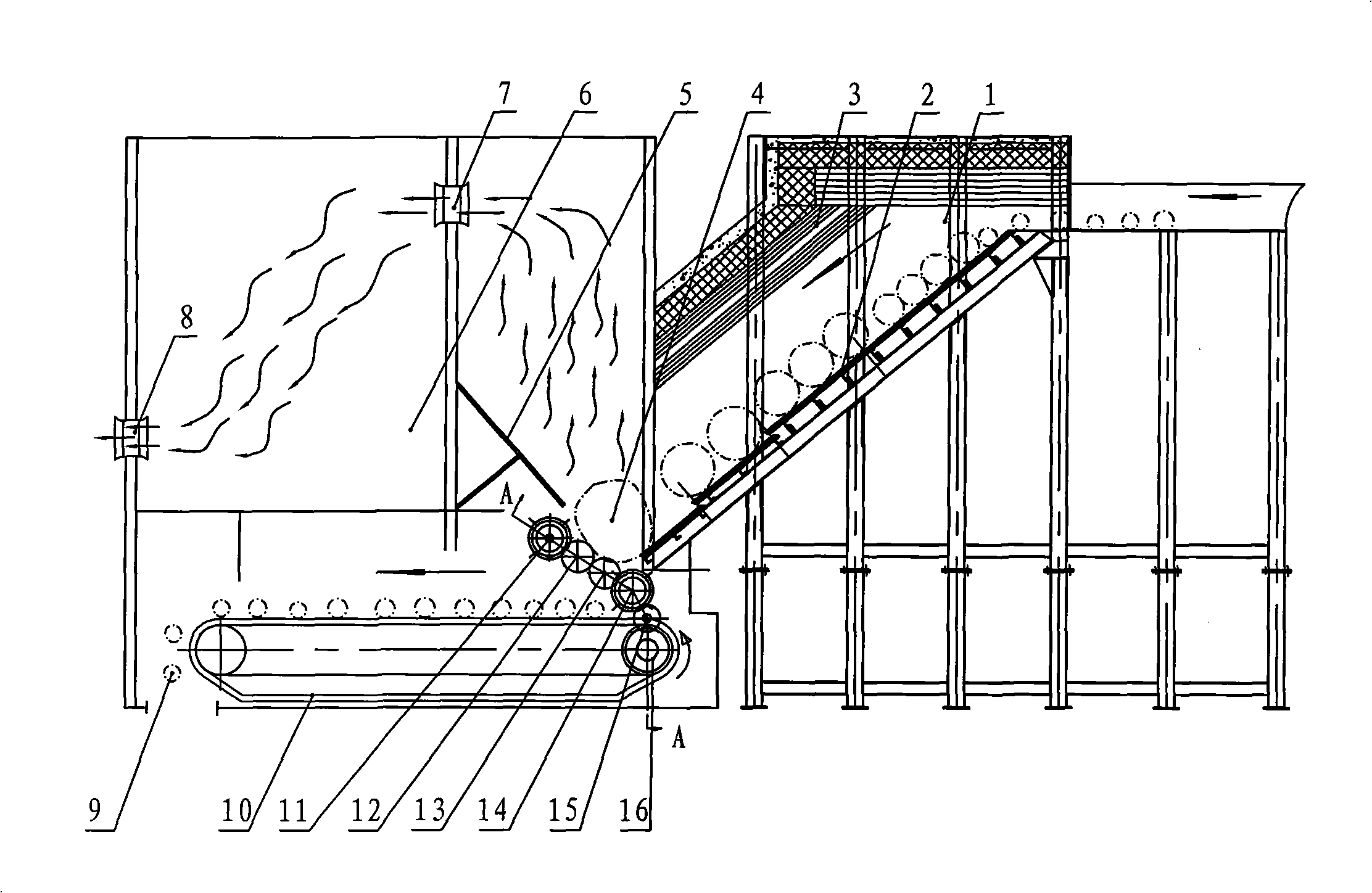

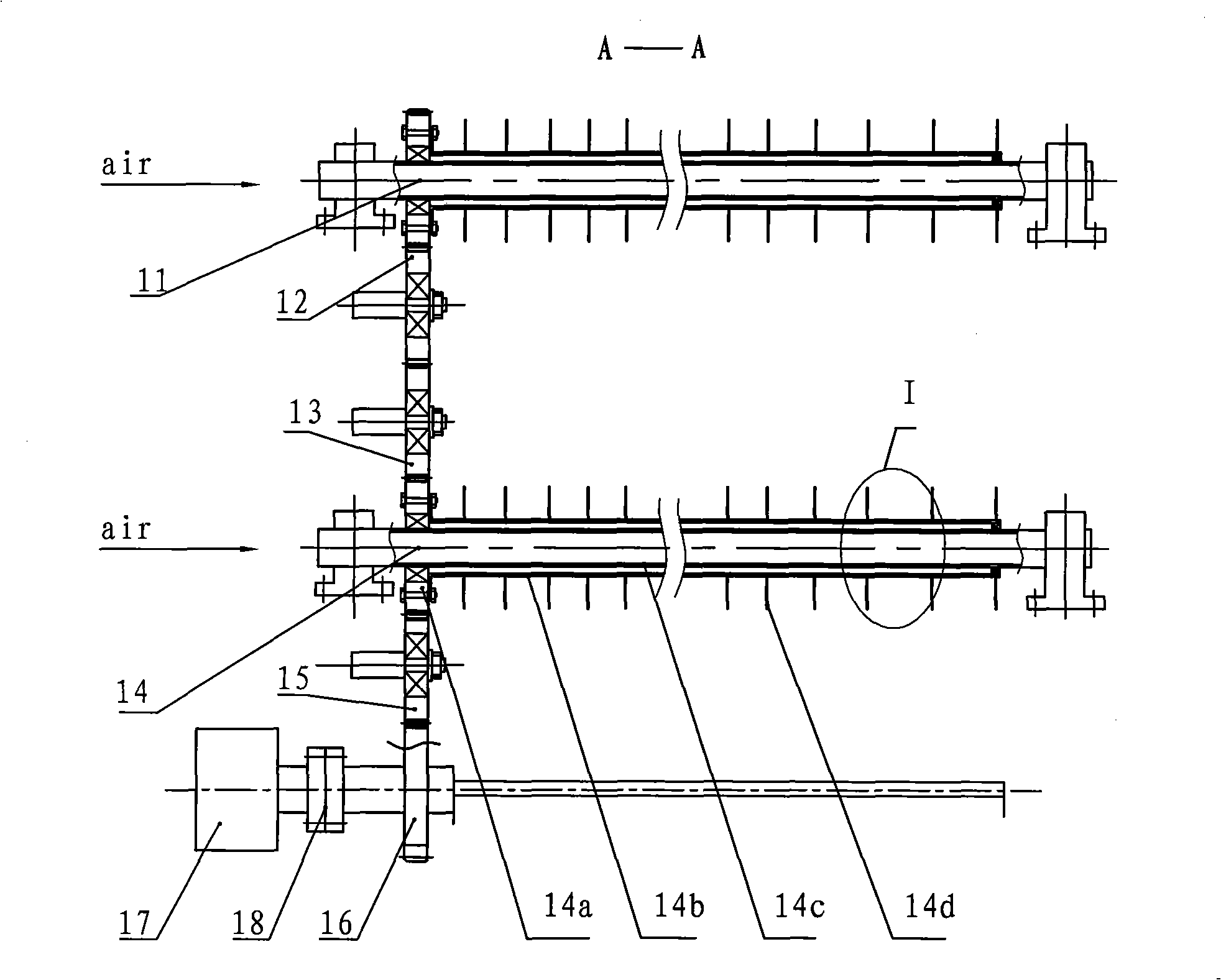

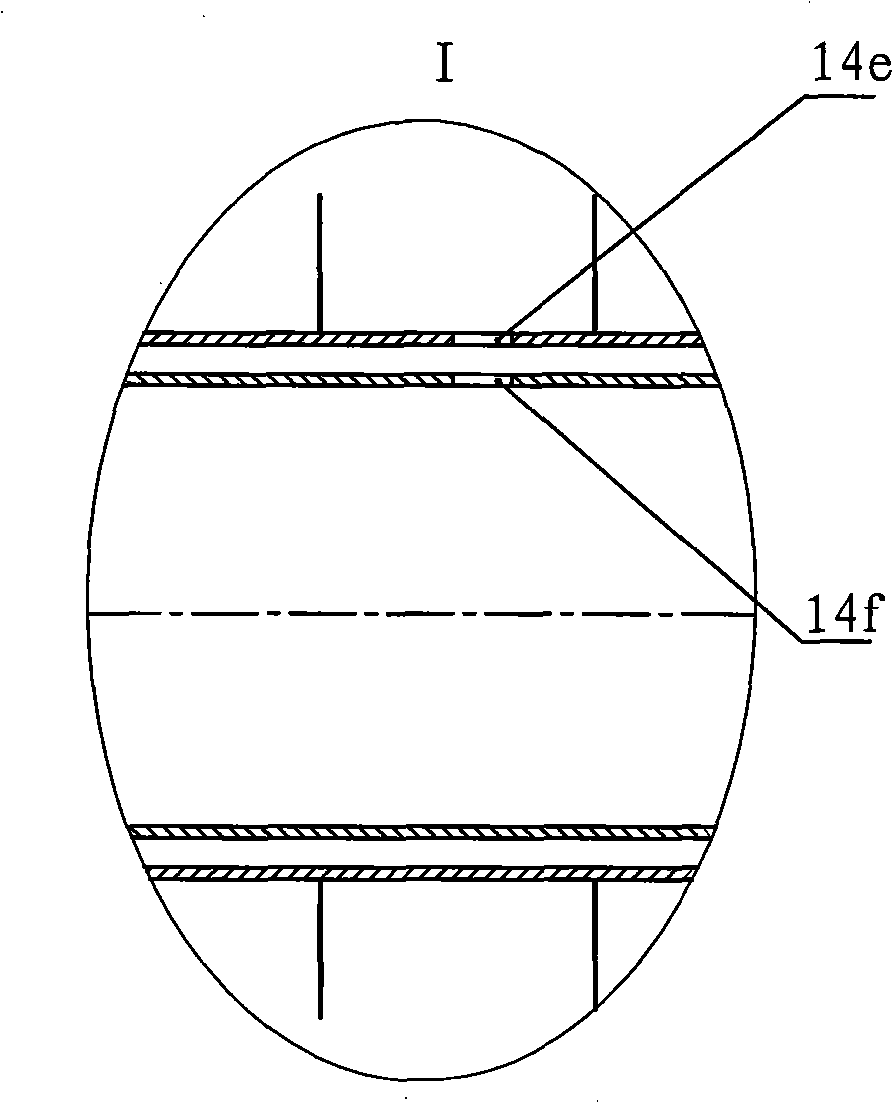

[0016] like figure 1 As shown, the garbage incinerator is mainly composed of a main combustion chamber 1, a stepped slideway 2, a furnace arch 3, a garbage slagging control plate 5, a secondary combustion chamber 6, smoke exhaust channels 7, 8 and a grate mechanism 10. Below the stepped slideway 2 and the secondary combustion chamber 6 are provided with two disturbance combustion-supporting devices 14 and 11, the disturbance combustion-supporting device 11 is between the stepped slideway 2 and the garbage slagging control plate 5, and the disturbance combustion-supporting device 14 is in the Below the ladder slide 2. see figure 1 , figure 2 , the grate mechanism 10 mainly consists of a drive motor, a grate speed control box 17, a coupling 18 and a grate surface; A driving gear 16 is provided, and the driving gear 16 drives the driven gear 14a on the disturbance combustion-supporting device 14 through the transition gear 15, and the driven gear 14a on the disturbance combus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com