Drum with fold line grooves

A technology of drums and wire ropes, which is applied in hoisting devices, spring mechanisms, etc., can solve the problems of high cost and long construction period, and achieve the effects of low cost, less processing, and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with embodiment (accompanying drawing):

[0028] The present invention takes the production of left-handed rope groove round steel or steel wire as an example, but does not limit the present invention.

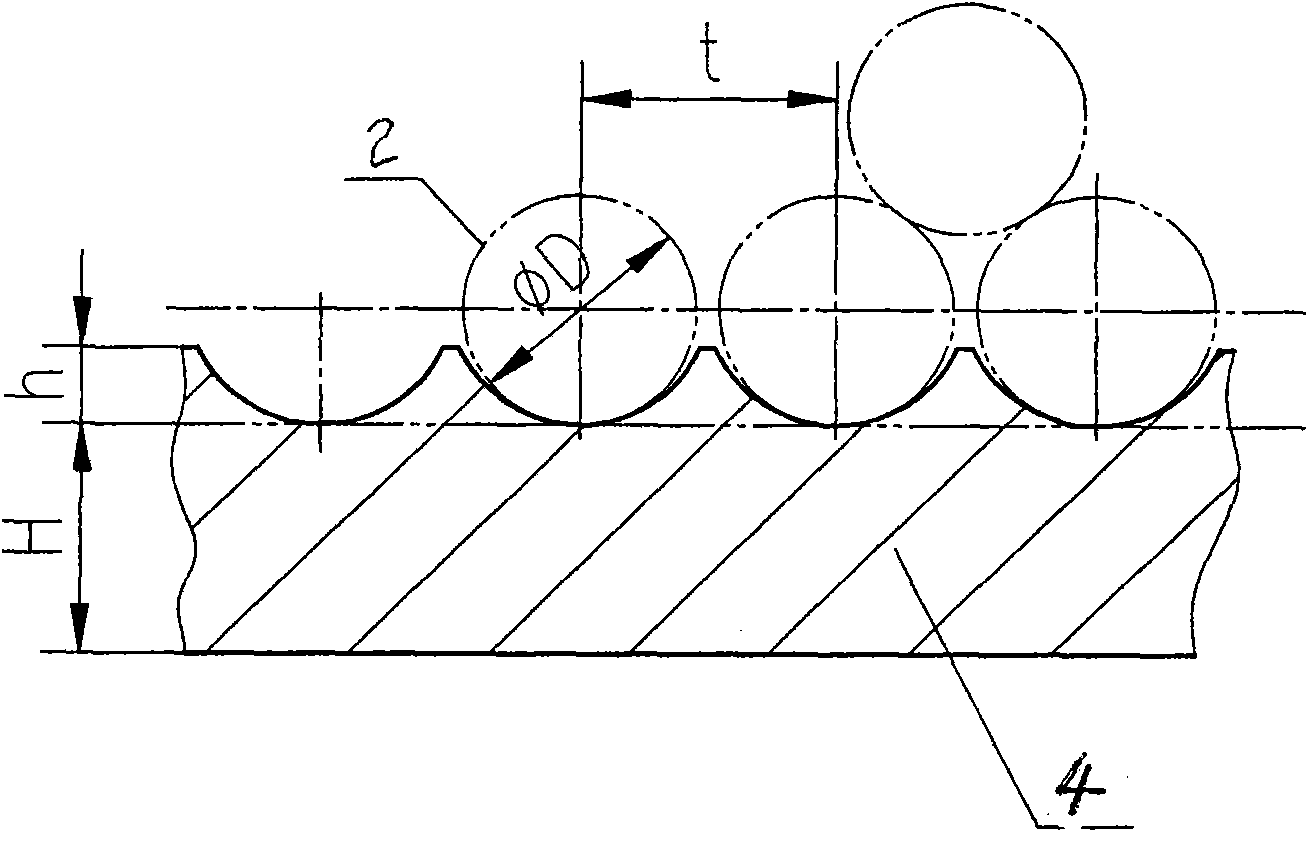

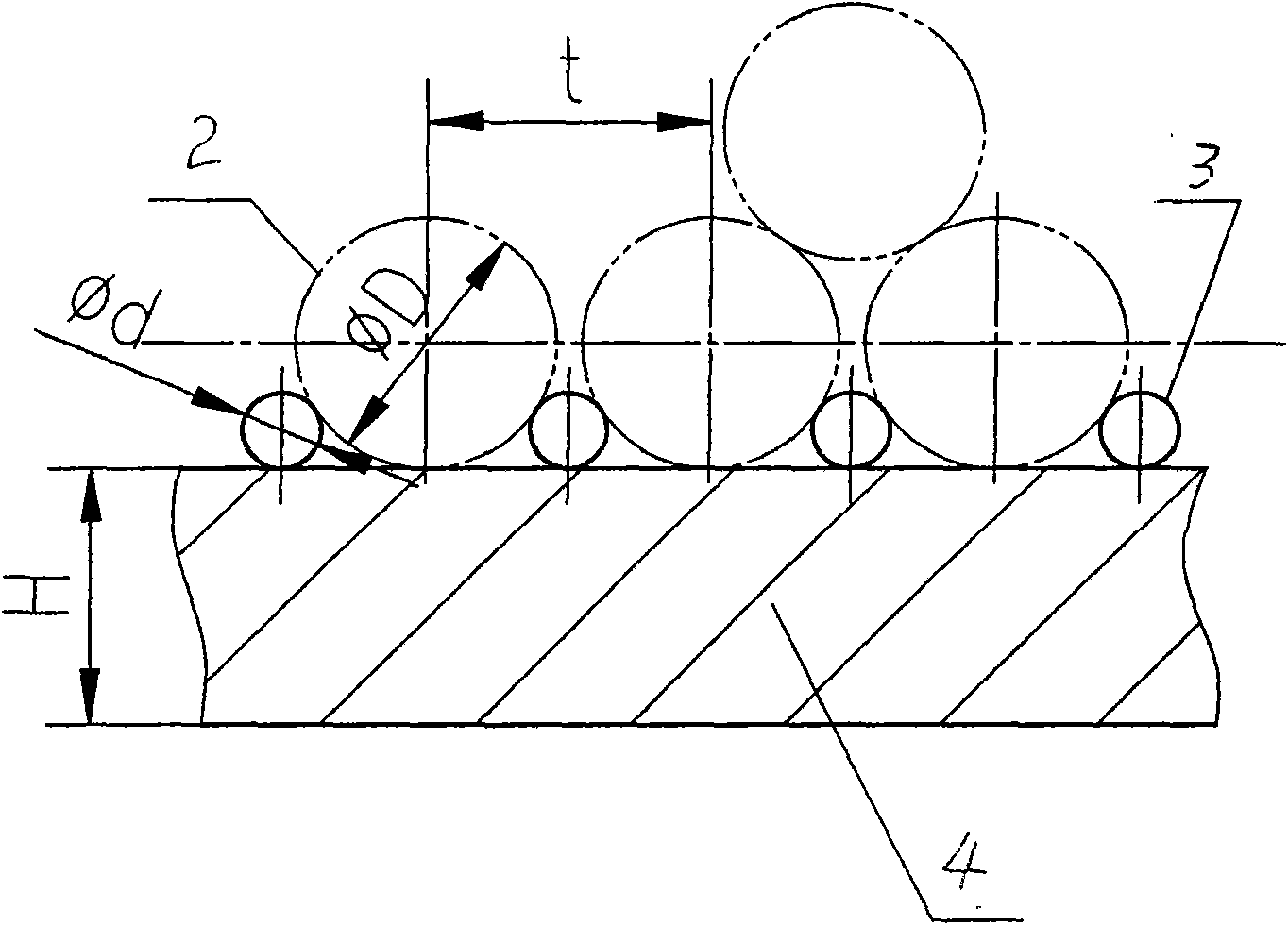

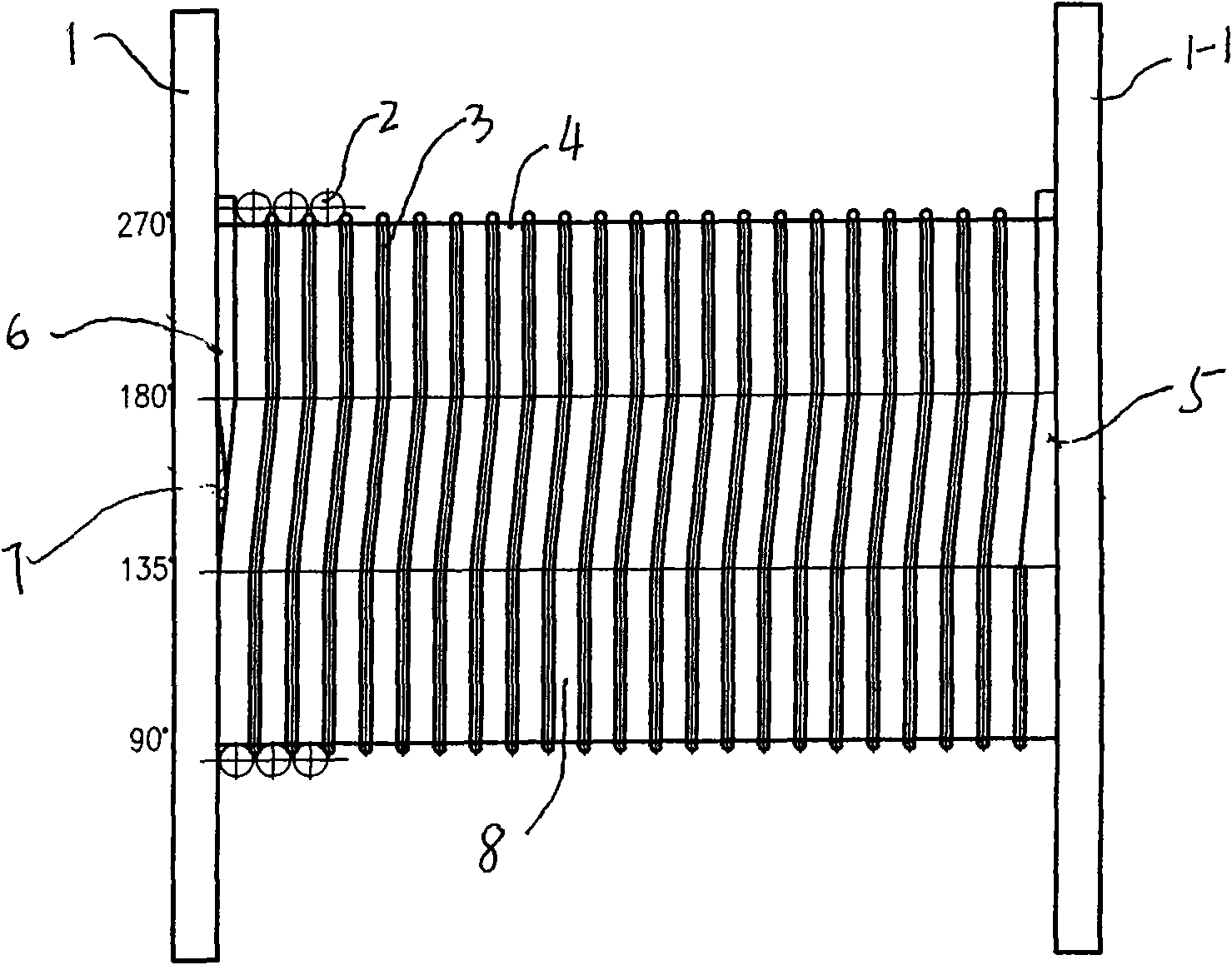

[0029] as the picture shows figure 2 , image 3 , Figure 4 Therefore, the broken line rope groove reel of the present invention includes a smooth reel base 4, a left baffle plate 1 fixed on the left end of the reel base body and a right baffle plate 1-1 at the right end, as well as a base that surrounds the reel in a fixed manner. The broken line rope groove 8 composed of round steel or steel wire 3 wound on the surface of the reel with the base body; at the rope inlet end of the broken line rope groove, there is a supporting rope protrusion with a table width gradually narrowing from the width to the reel base body in a fixed way. Station 6 (see Figure 7 ), the end of the folded line rope groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com