A packaging box with bar-code protection groove and method and apparatus for producing the same

A manufacturing method and packaging box technology, which is applied in packaging, transportation and packaging, bottle/can parts, etc., can solve the problem of surface barcode being worn and other problems, and achieve the effect of saving barcode printing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

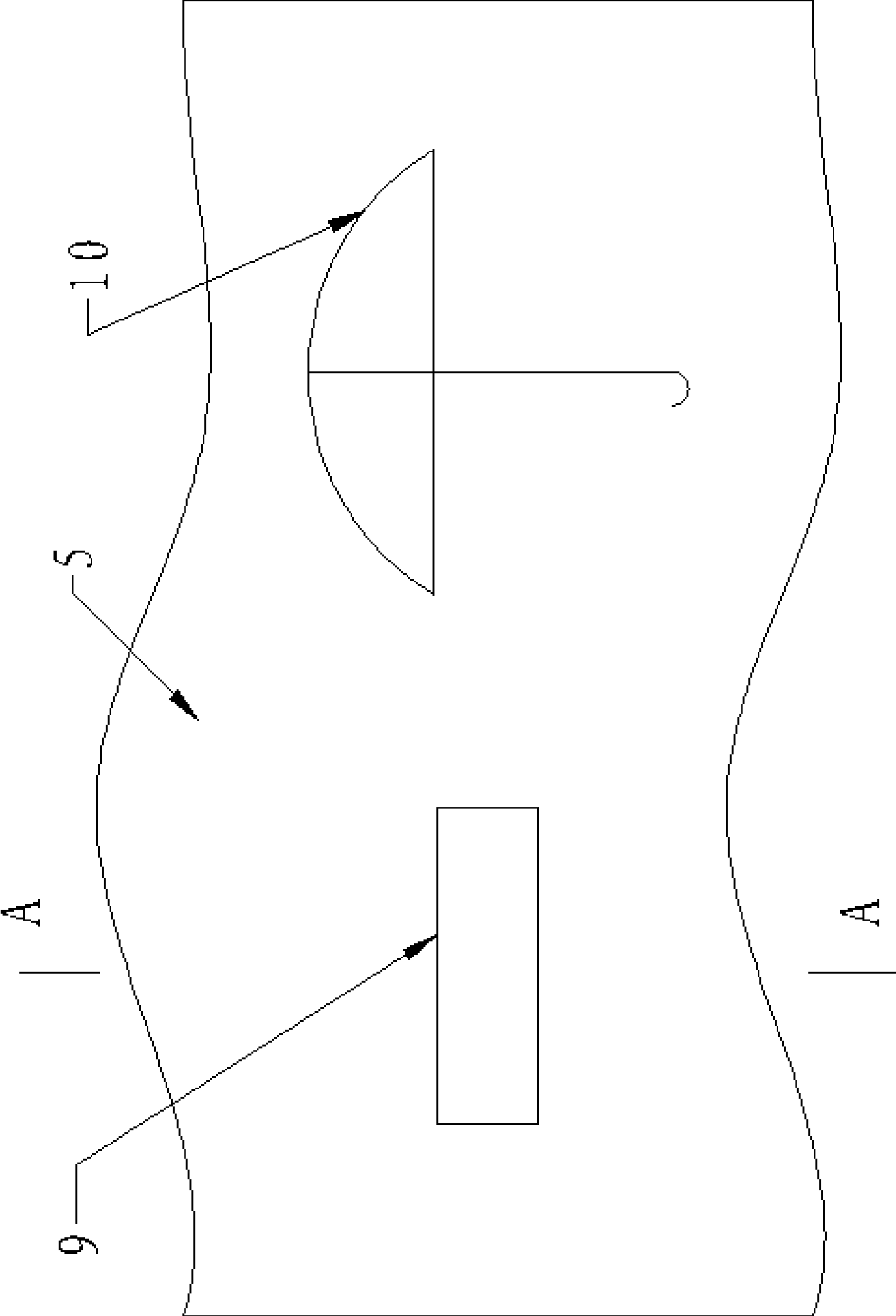

[0020] Use the following method to make a packing box with a barcode protection groove. The method includes barcode printing and box body printing. The barcode 9b and the box body 5 are printed separately. After the box body 5 is printed, the barcode protection box is processed on the box body 5 by color molding Groove 9, because it is colored molded, can form color block 9a in the barcode protection groove 9, is convenient for naked eyes identification, and sticks barcode 9b in described barcode protection groove 9.

[0021] The aforementioned method can be realized with the following manufacturing equipment, which includes barcode printing equipment, box body printing equipment and box body coloring molding equipment.

Embodiment 2

[0023] Use the following method to make a packing box with a barcode protection groove. The method includes barcode printing and box body printing. The barcode 9b is printed separately from the box body 5. When the box body is printed, the barcode protection groove 9 is processed on the box body 5. Paste the barcode 9b in the barcode protection groove 9 .

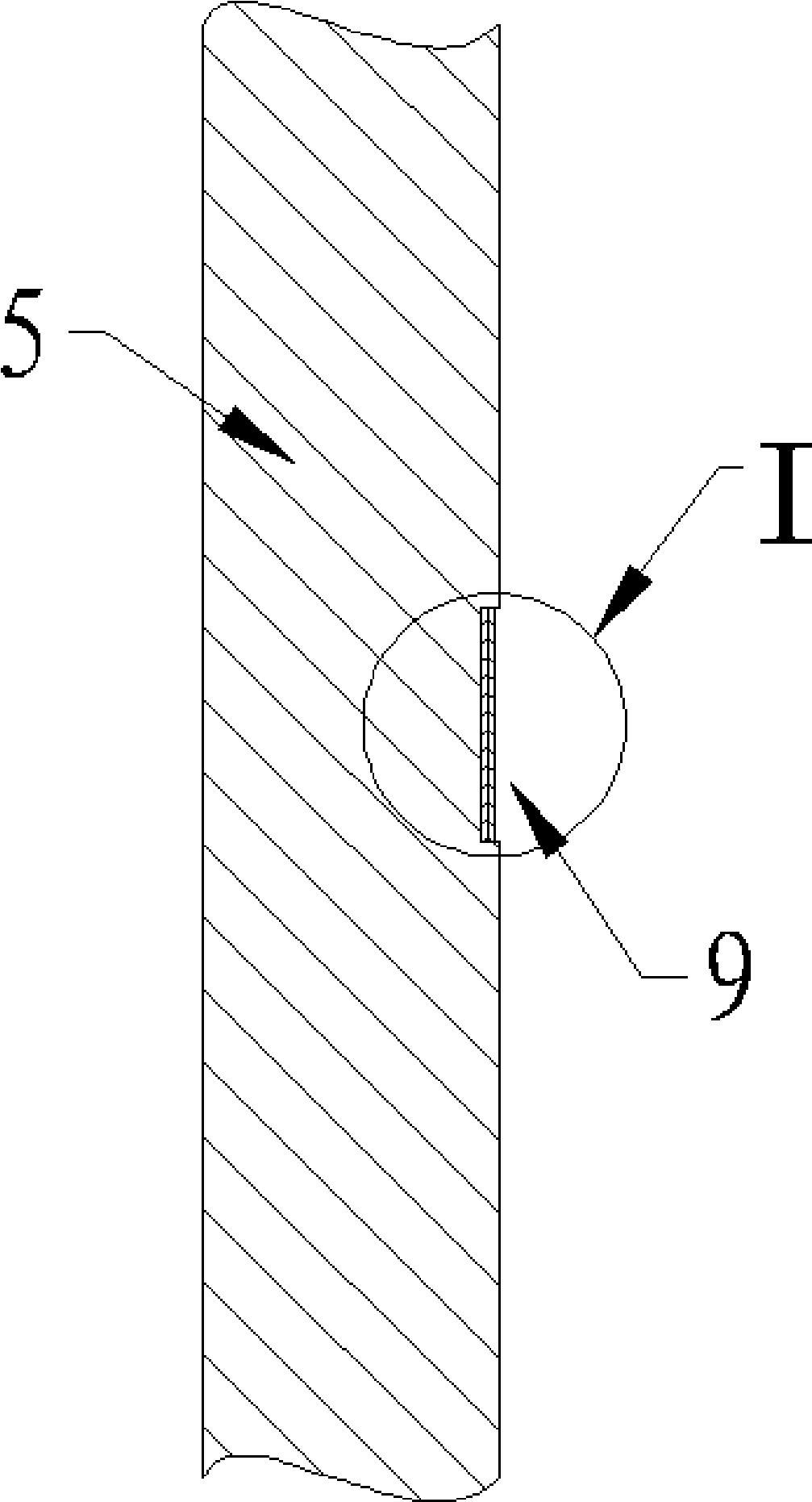

[0024] The depth of the barcode protection groove 9 is 0.5-1.0 mm, which does not damage the surface of the box body 5 and hardly affects the strength of the box body 5 .

[0025] Further, when the box is printed, the color block 9a is also printed on the barcode protection groove 9, and the sticking position of the barcode 9b can be visually observed according to the position of the color block 9a.

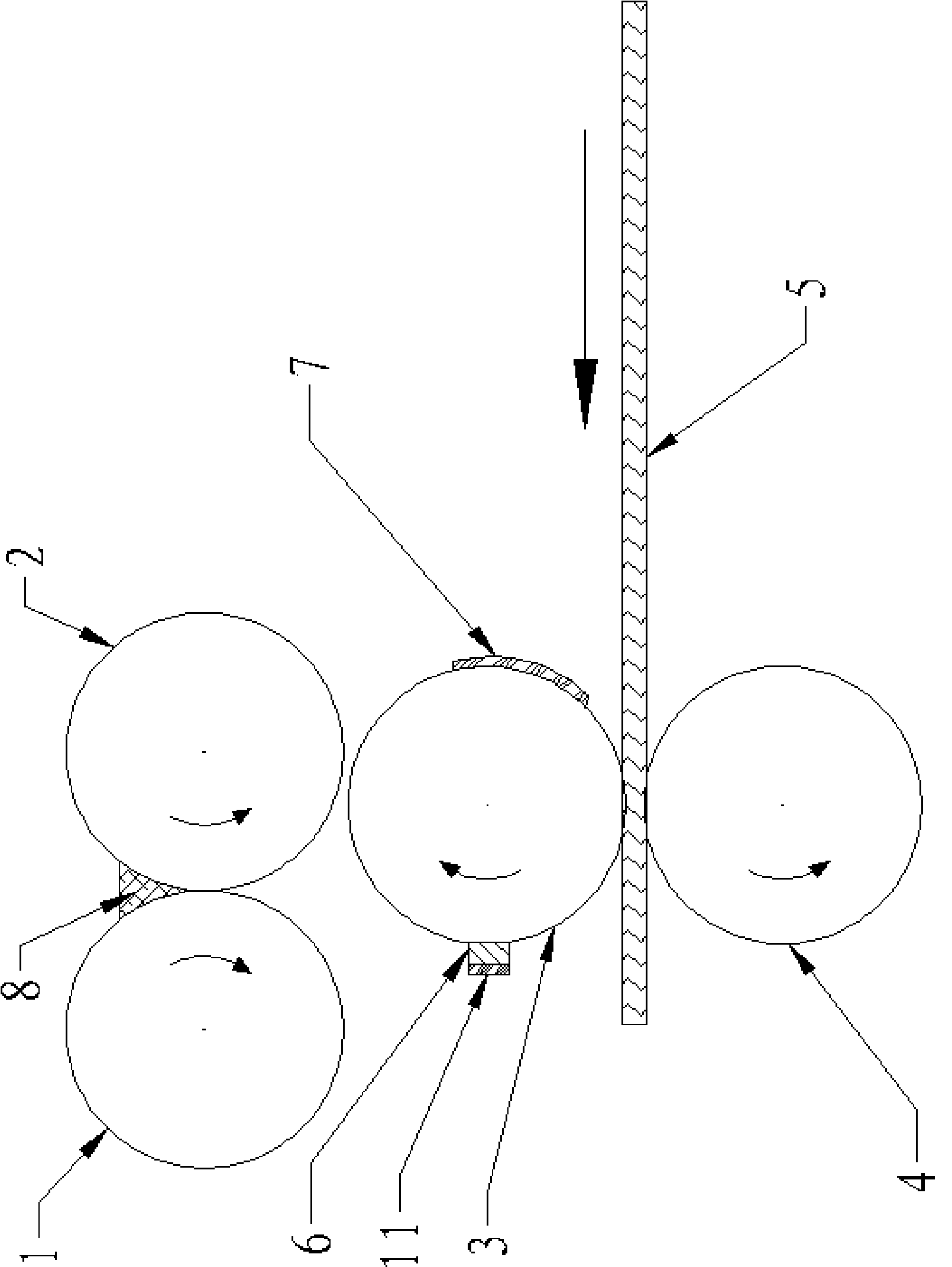

[0026] Such as figure 1 As shown, the aforementioned method can be realized with the following manufacturing equipment, which includes barcode printing equipment and box printing equipment, and the box printing equipment incl...

Embodiment 3

[0033] Use the following method to make a packing box with a barcode protection groove. The method includes barcode printing and box body printing. When the box body is printed, a barcode protection groove 9 is processed on the box body 5, and the barcode 9b is printed on the barcode In the protection groove 9.

[0034] Such as figure 1 As shown, the aforementioned method can be realized with the following production equipment, which includes box printing equipment, and the box printing equipment includes a printing unit provided with a groove pre-printing tooling 6, and a barcode is attached to the surface of the groove pre-printing tooling 6 printing plate 11. When printing, the box body 5 passes through the printing plate roller 3 and the pressure roller 4. Under the pressure of the two rollers, the box body 5 is pressed out of the barcode protection groove 9 by the groove pre-printing tooling 6; at the same time, the groove pre-printed The barcode printing plate 11 on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com