Bode plot for starting-stopping process analysis

A process analysis, starting and stopping technology, applied in the field of Bode diagrams, can solve problems such as differences in Bode diagrams, inconvenient establishment of Bode diagrams, and incomplete information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

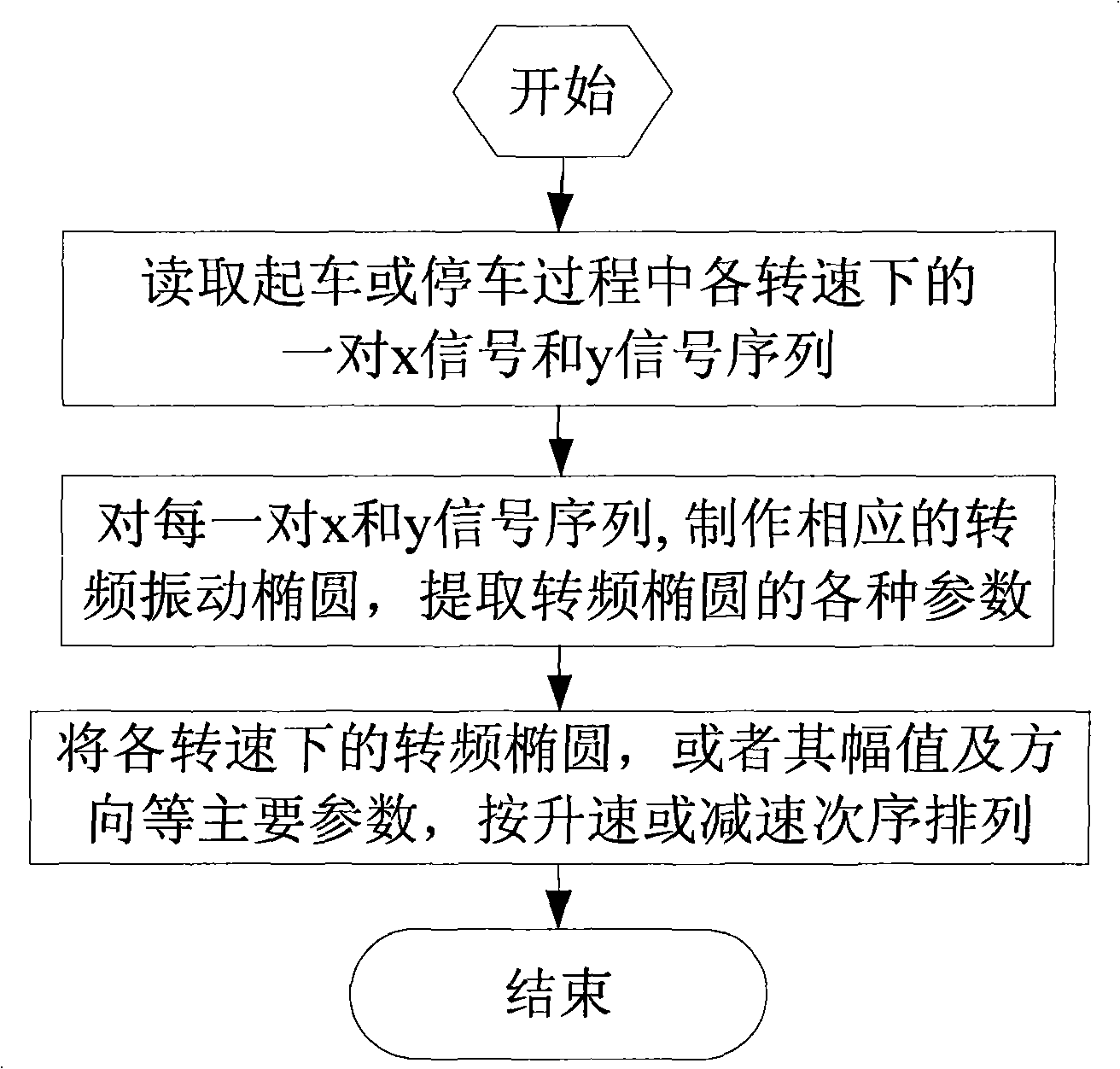

Method used

Image

Examples

specific Embodiment approach

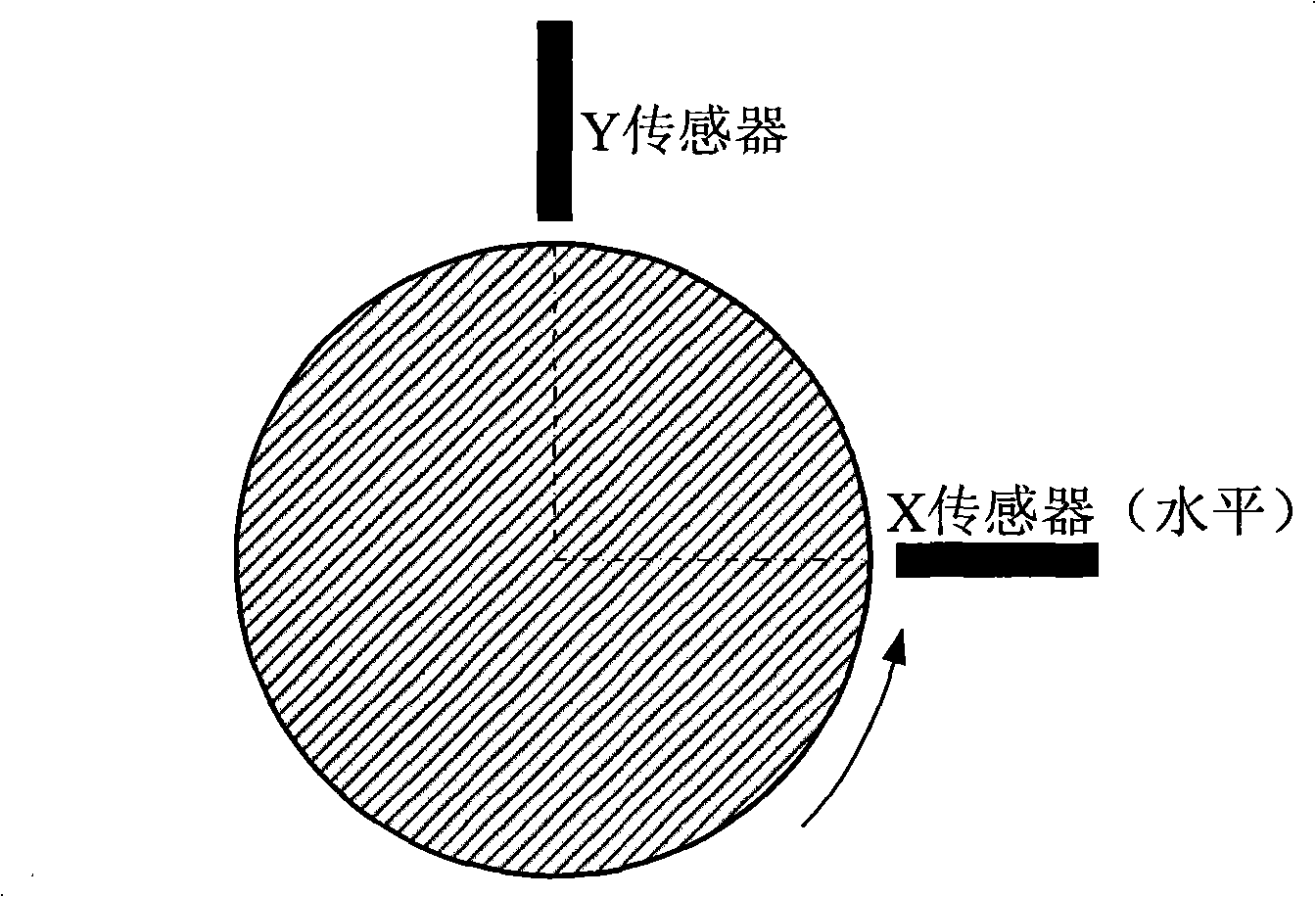

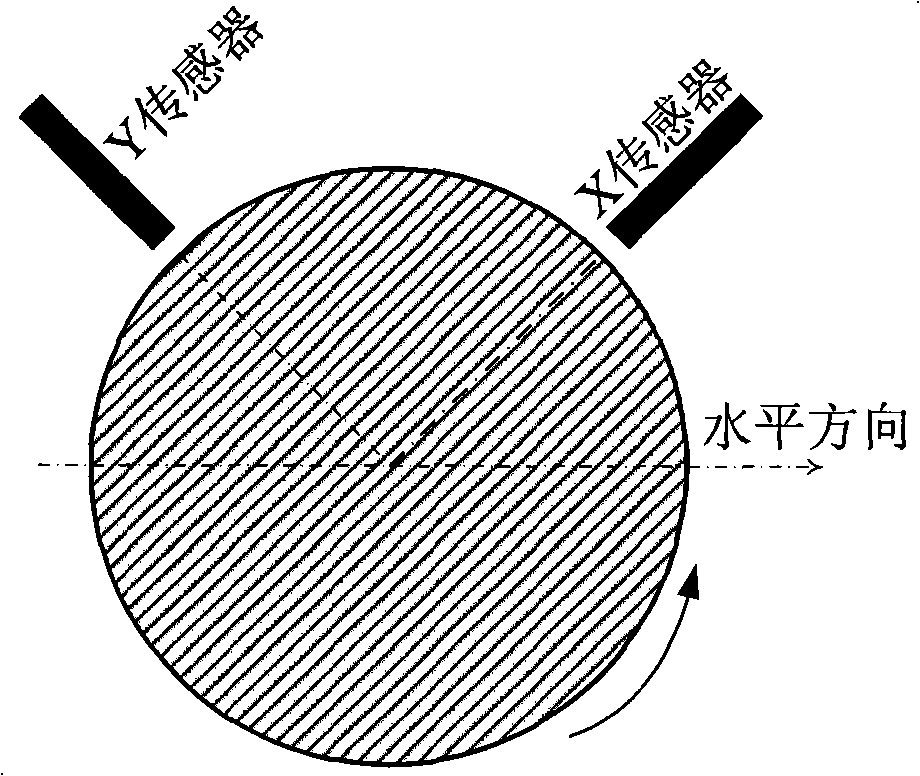

[0038] Simultaneously measure the x and y vibration displacement signal sequences of the rotating shaft at various speeds during the start-up process of a unit. The arrangement of the X and Y sensors is as follows image 3shown. For each pair of x signal and y signal sequences collected synchronously, the sampling rate is 2kHz, and the number of sampling points is N=1024 points. The specific implementation is as follows:

[0039] (1) Read the sequence pair of x signal and y signal at each speed during the starting process, the sampling rate is 2kHz, and the number of sampling points is N=1024.

[0040] (2) Perform fast discrete Fourier transform (FFT) on a pair of x-signal and y-signal sequences at each rotational speed, and the result is a 1024-point complex sequence.

[0041] (3) Based on the fast Fourier transform results of the two signals of x and y, obtain their respective Fourier series, and obtain parameters of a total of N / 2=512 harmonic components from small to lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com