Crank mop

A crank and mop technology, which is applied in the field of daily necessities, can solve the problems of difficult rotation, falling back to the ground, energy waste, etc., and achieve the effects of reduced labor intensity, improved labor efficiency, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

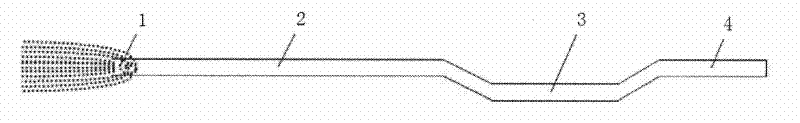

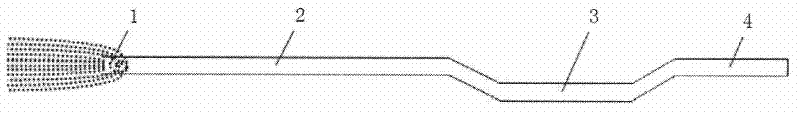

[0010] Such as figure 1 As shown, the crank mop of the present invention includes a mop head 1 and a crank mop bar 2, which can be connected in various ways between the mop head 1 and the crank mop bar 2, and the mop head 1 can also adopt the mop head of the prior art; the crank mop The rod 2 is provided with a forehand eccentric grasping part 3, which is located between the connection part of the mop head 1 and the rear hand grasping part 4 for the front hand to grasp when wiping the floor, and the center of the forehand eccentric grasping part 3. The tangent of the axis or the central axis is parallel to the connection center line between the connection part of the crank mop rod 2 and the mop head 1 to the rear hand grip part 4, and deviates from a certain distance; the front hand eccentric grip part 3 and Other parts of the crank mop bar 2 are connected as a whole.

[0011] When using the present invention to wipe the ground, one hand is placed on the eccentric grasping pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com