Composite three-dimensional laser measurement system and measurement method

A three-dimensional measurement and composite technology, applied in photogrammetry/video measurement, measurement devices, surveying and navigation, etc., can solve problems such as low measurement efficiency, easy wear of probes, and inability to measure soft objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

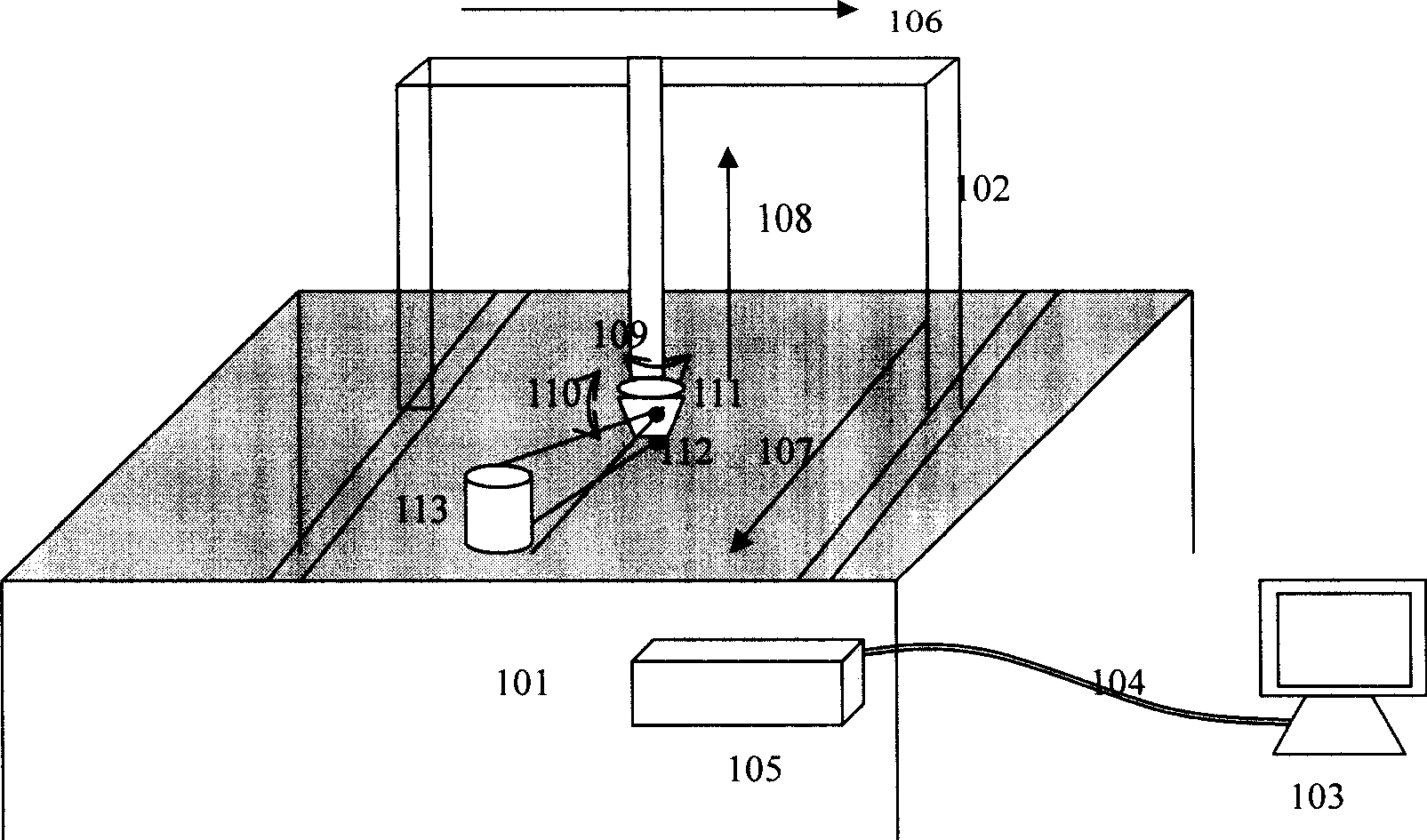

[0043] The present invention uses computer vision and optical sensing technology to realize intelligent three-dimensional scanning and detection of objects. The system is composed of software and hardware. figure 1 It is a diagram of the hardware structure of the system, including. Basic hardware composition:

[0044] 101 Mechanical platform It is composed of marble platform, which mainly ensures the flatness and stability of the system platform;

[0045] 102 Gantry frame The overall frame for the installation of the storage measuring head and related motion axes

[0046] 103 Computer system Operate and control the system, man-machine dialogue

[0047] 104 Link cable The link between the host computer and the console of the mechanical platform

[0048] 105 Servo control system drives the movement axis to move precisely

[0049] The five-axis system consists of:

[0050] 106 X-axis It is the horizontal movement axis responsible for the left and right movement of the laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com