Changing hub of tide generating set

A technology for generating sets and propeller hubs, applied in the field of pitch-changing hubs, which can solve problems such as sealing, driving force, and pitch-changing angle, etc., and achieve simple and reliable pitch-changing mechanisms, good sealing, and avoid pipeline entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

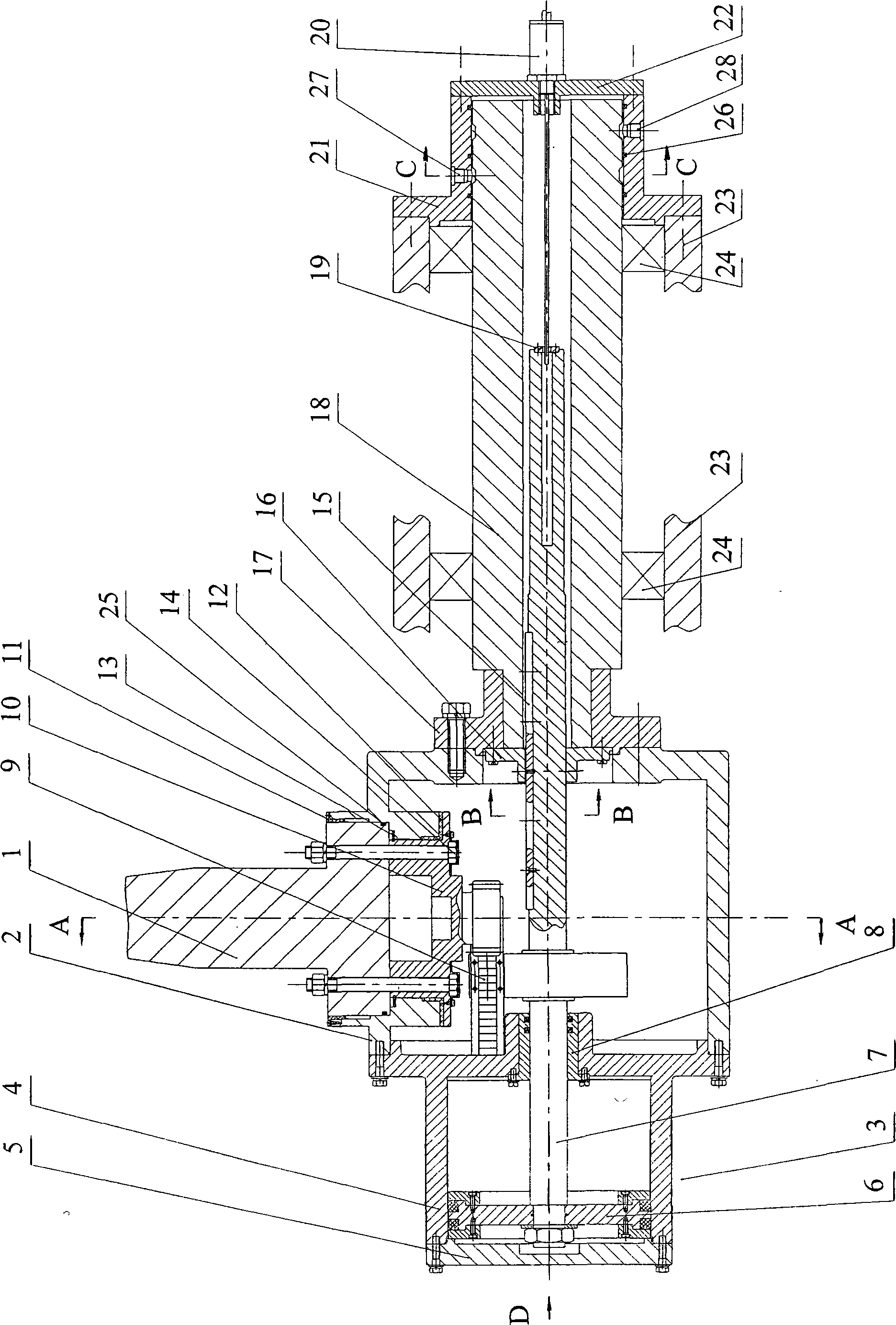

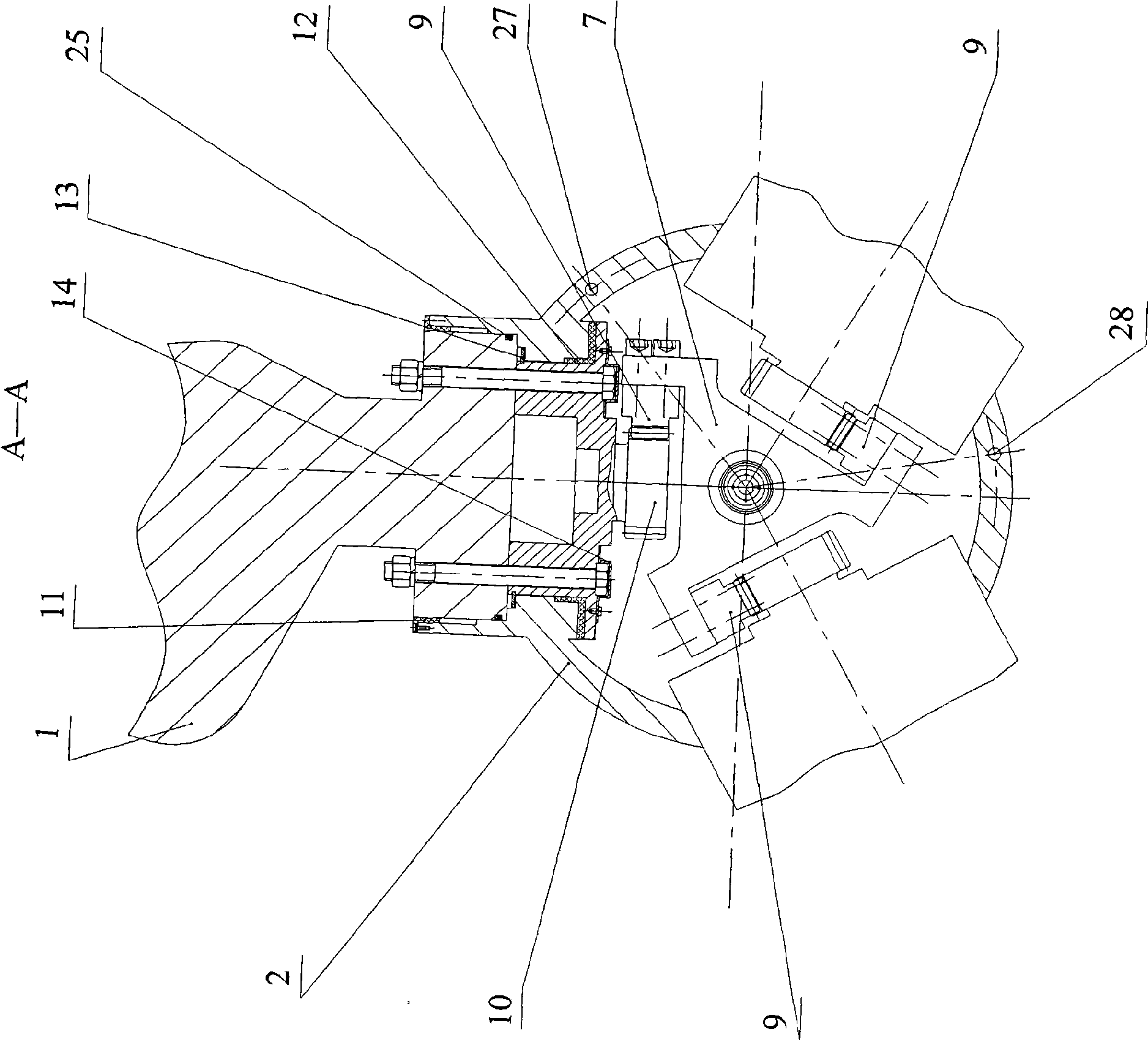

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

[0024] Such as figure 1 As shown, the hydraulic cylinder 3 of the present invention, as a part of the entire hub shell, is installed directly in front of the hub main body 2 by screws, and the axis of the hydraulic cylinder barrel 4 is parallel to the direction of the flow. The left end of the piston push rod 7 is threadedly connected with the hydraulic cylinder piston 6, and the front support 8 of the push rod supporting the front end of the piston push rod 7 is fixedly installed in the cylinder barrel 4 of the hydraulic cylinder. U-shaped sealing ring to prevent oil leakage of the hydraulic cylinder.

[0025] Such as figure 1 , figure 2 As shown, each side of the triangular push plate on the piston push rod 7 in the hub main body 2 is respectively installed with a rack 9 parallel to the piston push rod 7 through screws, and the gears at one end of the three gear s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com