Inertial dust precollecting air flow uniform distribution device

A technology of uniform air distribution and pre-collection of dust, which is applied to the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles. Dust adsorption capacity and filter resistance, good dust settlement effect, and the effect of reducing the number of cleaning times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

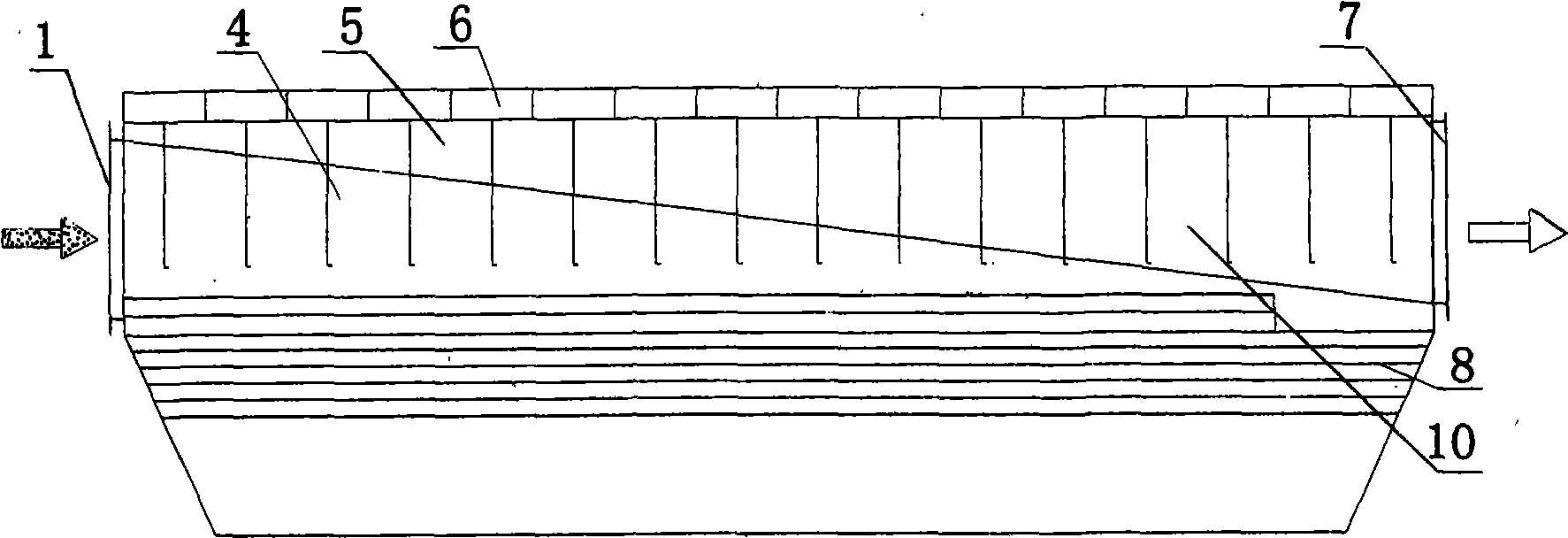

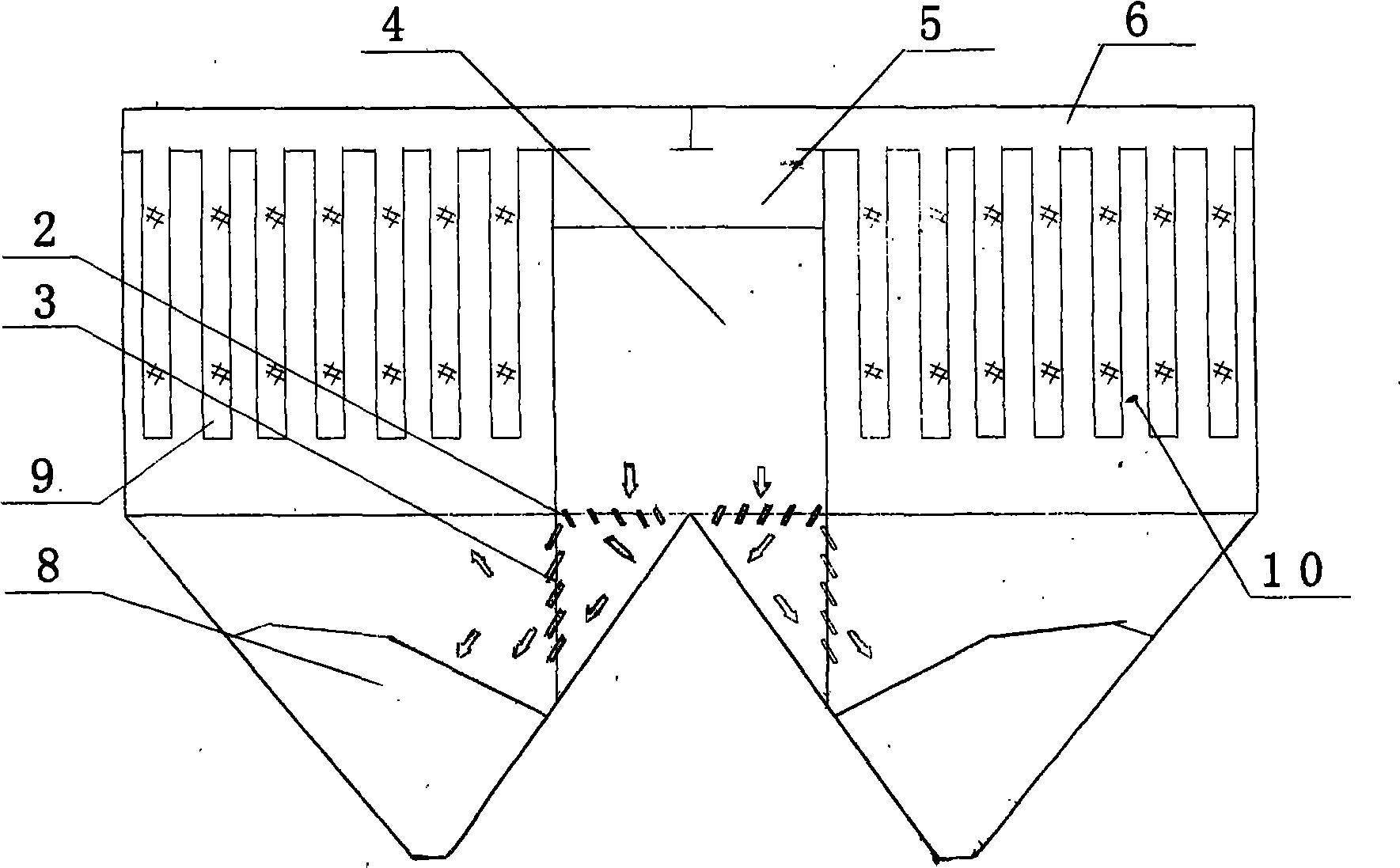

[0013] As shown in the figure, it is an inertial pre-collection dust air distribution device. Horizontal and vertical louver-shaped deflectors are arranged between the air inlet channel 4 and the ash bucket 8 in the air channel. The horizontal louver-shaped deflector 2 is arranged in the horizontal direction of the air duct and the entrance of the ash hopper, and its angle with the horizontal line is 75-55 degrees, and the average wind speed of the cross-section is designed to be 2-3 m / s. The vertical louver-shaped deflector 3 is set in the vertical direction between the air duct and the entrance of the ash hopper, and the angle between it and the vertical line is 150-170 degrees. The average wind speed of the cross-section is designed to be 2-3 m / s. Ascent speed 0.7-1 m / s.

[0014] The louver is made of 5mm steel plate pressed into a certain angle or welded.

[0015] How it works

[0016] The dust-laden gas enters the air inlet channel 4 from the air inlet flange port 1, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com