Motor drive control apparatus and motor drive control system

一种电动机、无刷电动机的技术,应用在电子换向电动机控制、控制系统、单个电动机转速/转矩控制等方向,能够解决霍尔IC配置不同、控制部算法复杂、很难最佳方法等问题,达到减小变动幅度、抑制转矩脉动、抑制噪音和振动的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0063] (1) The structure of the whole and the motor

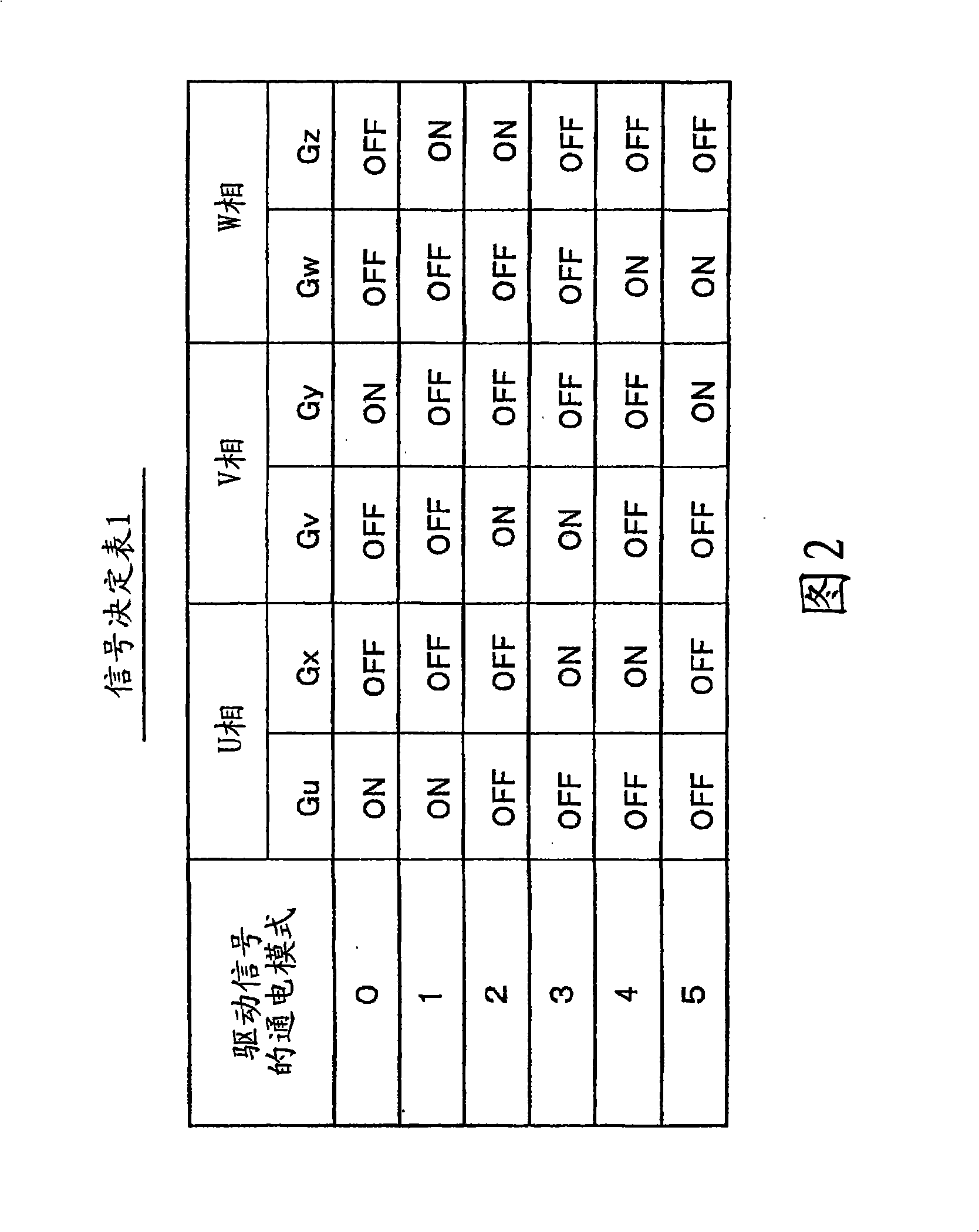

[0064] figure 1 It is an overall configuration diagram of the motor drive control system 100 including the motor 51 and the motor drive control device 1 for controlling the drive of the motor. Here, examples of the type of motor generally include a DC motor, an AC motor, a stepping motor, a brushless DC motor, and the like. In this embodiment, a brushless DC motor is used.

[0065] The brushless DC motor 51 is, for example, a fan motor used for a fan 61 of an outdoor unit of an air conditioner, and has a stator 52 and a rotor 53 .

[0066] The stator 52 includes star-connected U-phase, V-phase, and W-phase drive coils Lu, Lv, and Lw. One ends of the drive coils Lu, Lv, and Lw of the U-phase, V-phase, and W-phase are respectively connected to the drive coil terminals TU, TV, and TW of the U-phase, V-phase, and W-phase, and the other ends thereof are all connected to the terminal TN. These three-phase drive coils Lu, Lv, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com