Element which generates a magnetic field

A component and magnetic field technology, applied in the field of components that generate magnetic fields, can solve the problems of insufficient absorption force and tightening torque, unsuitable nuts, etc., and achieve the effect of saving cost and production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

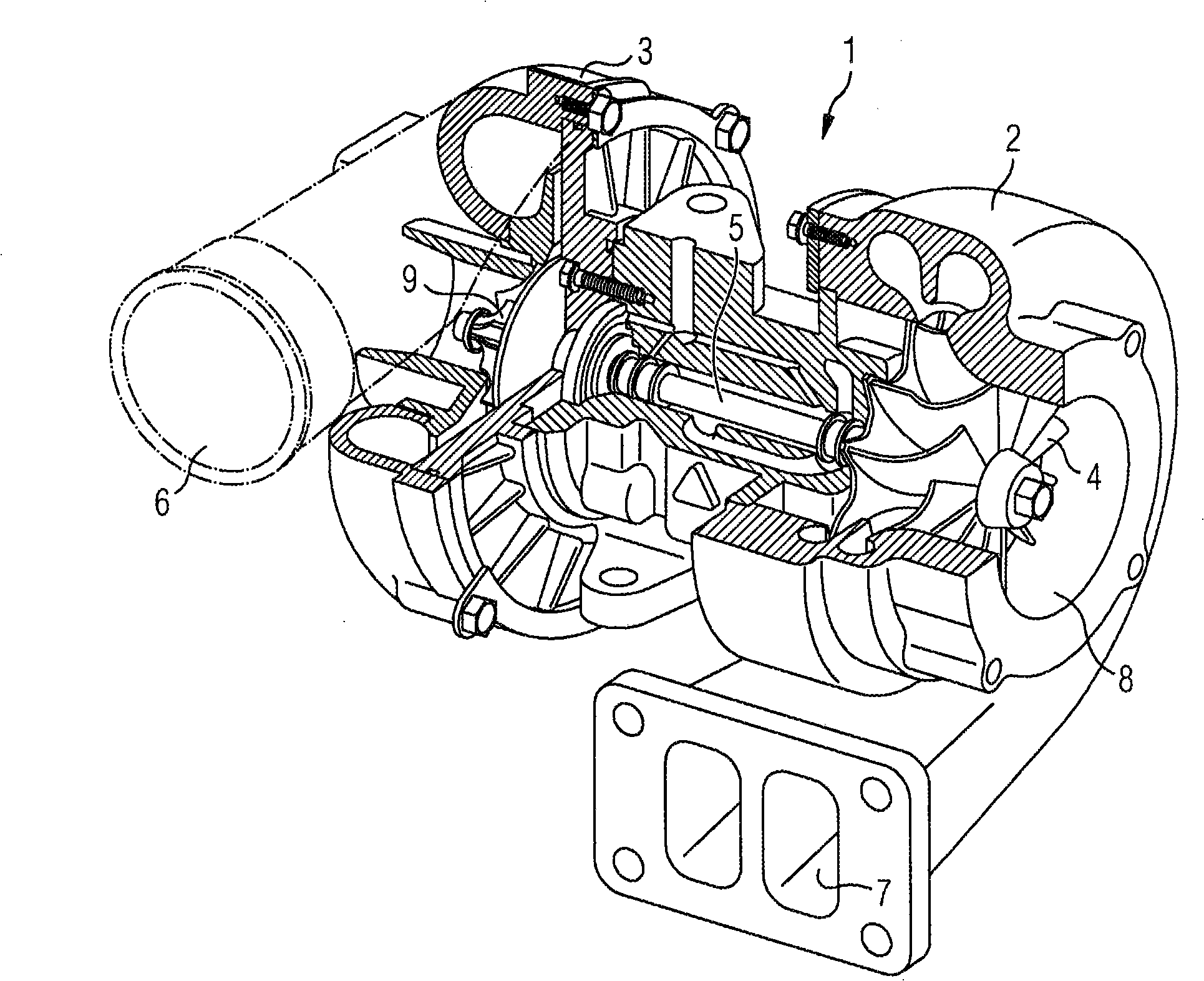

[0025] figure 1 An exhaust gas turbocharger 1 with a turbine 2 and a compressor 3 is shown. The compressor wheel 9 is rotatably mounted in the compressor 3 and connected to the turbine shaft 5 . The turbine shaft 5 is also mounted rotatably and is connected at its other end to the turbine wheel 4 . The combination of the compressor wheel 9 , the turbine shaft 5 and the turbine wheel 4 is also referred to as a rotor assembly. Hot exhaust gases from the internal combustion engine, not shown here, pass through the turbine inlet 7 into the turbine 2 , wherein the turbine wheel 4 is in rotation. The exhaust gas flow leaves the turbine 2 through the turbine outlet 8 . The turbine wheel 4 is connected to a compressor wheel 9 via a turbine shaft 5 . The turbine 2 thus drives the compressor 3 . In the compressor 3 , air is sucked in via the air inlet 16 , subsequently compressed in the compressor 3 and delivered to the internal combustion engine via the air outlet 6 .

[0026] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com