Motor matching control system for hydraulic machine

A technology of control system and hydraulic system, which is applied in the field of hydraulic machine control, can solve the problems of lower production efficiency, waste of energy, poor flexibility, etc., and achieve the effects of convenient maintenance, optimized configuration, and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are listed hereby, and the motor matching control system of the hydraulic press of the present invention is described in detail with reference to the accompanying drawings as follows:

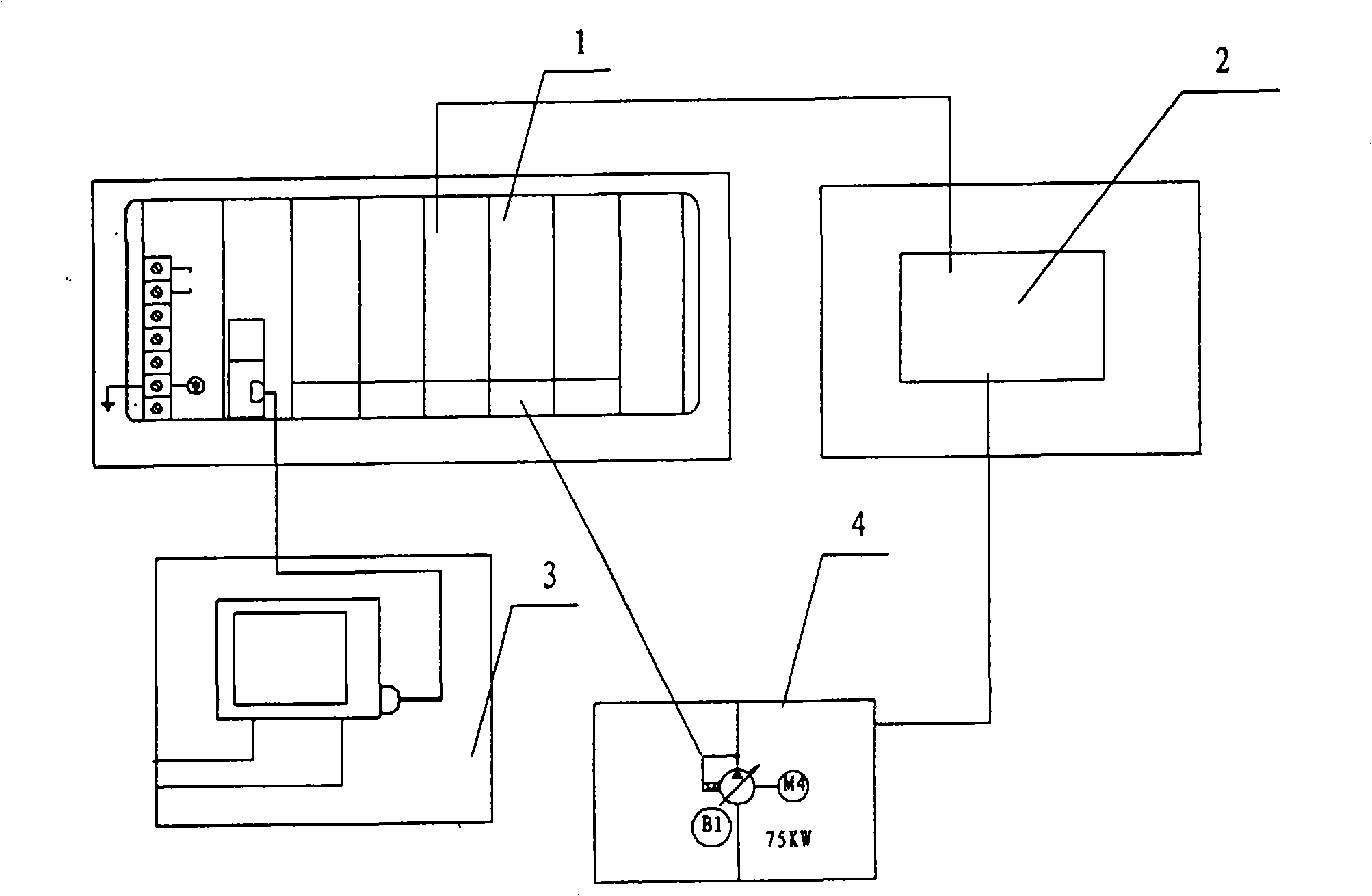

[0021] Such as figure 1 As shown, the motor matching control system of the hydraulic machine of the present invention includes a hydraulic machine PLC 1, a motor start switch assembly 2 connected to the hydraulic machine PLC 1 and arranged in the control box of the hydraulic machine, and a hydraulic system motor connected to the motor start switch assembly 2 4, and the touch screen 3 connected to the hydraulic machine PLC 1, and the motor start circuit 2 and the input and output circuit of the hydraulic machine PLC 1 respectively connected to the hydraulic machine PLC 1 and the hydraulic system motor 4 are also provided.

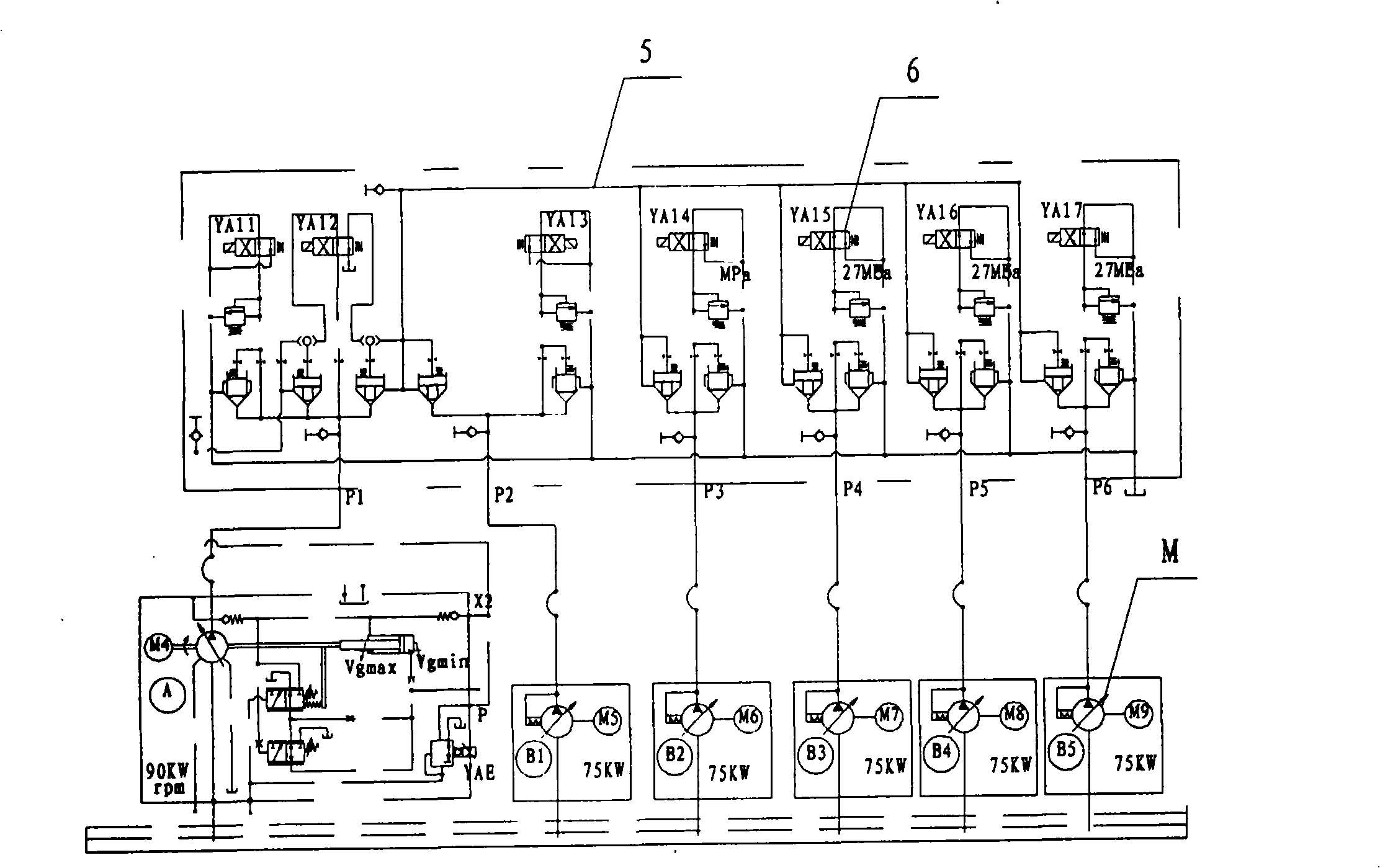

[0022] Such as figure 2 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com