Process and method for producing lens with multi-prescription by one mould

It is a technology of one mold with multiple configurations and production technology, which can be applied to other household appliances, household appliances, optical components, etc., and can solve problems such as time-consuming, labor-intensive, and high-cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment the present invention is described in further detail.

[0020] In the embodiment of the present invention, the outer diameter of the lens product is fixed, the myopia is 70mm, and the presbyopia is 65mm.

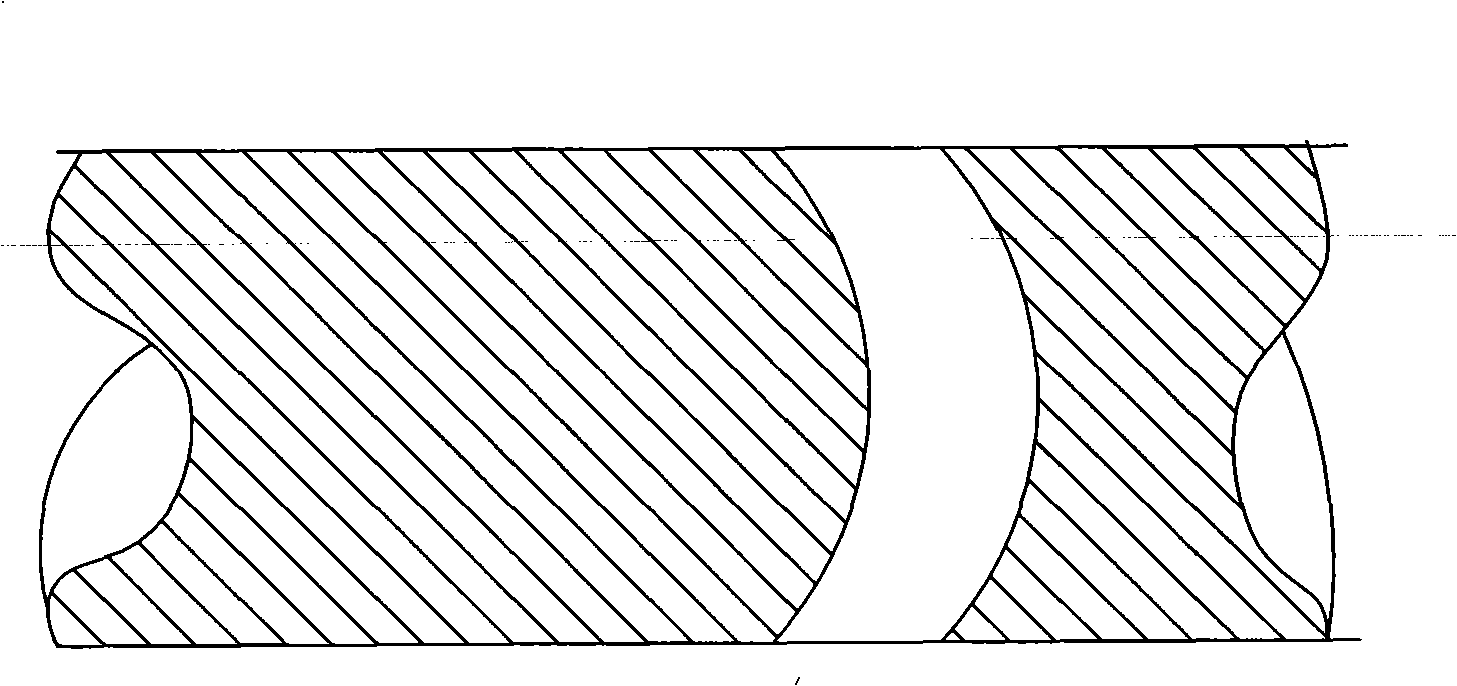

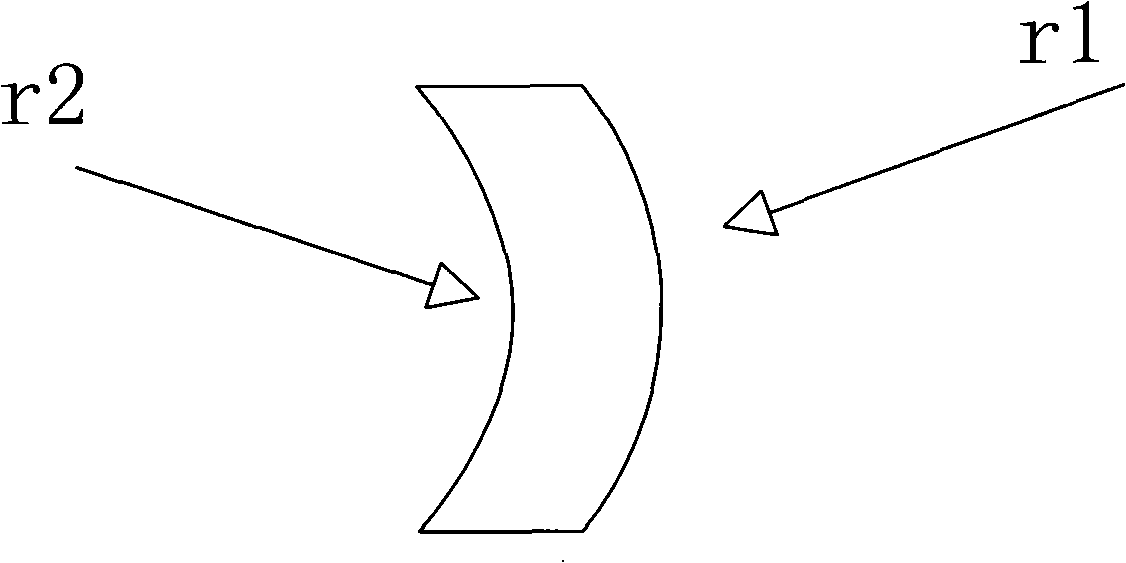

[0021] In the case of a fixed female mold core, changing the male mold core (that is, the r2 of the lens) can achieve the production of the required lens, such as figure 1 , figure 2 As shown, the principle is: the lens is formed by two refraction surfaces (r1, r2) with a certain curvature and an optically transparent body contained therein, and the two refraction surfaces of the PC lens are the male and female molds of the mold Ren, the optically transparent body is the PC material (the main characteristic refractive index), and the degree of the lens mainly depends on the curvature of the two refractive surfaces and the refractive index of the material. The relationship between them is as follows:

[0022] DS=100 / f

[0023] f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com