Lockset

A technology of locks and lock cylinders, applied in the field of locks, which can solve the problems of large length, complex structure, and large volume of the lock sleeve, and achieve the effect of simplifying the structure and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

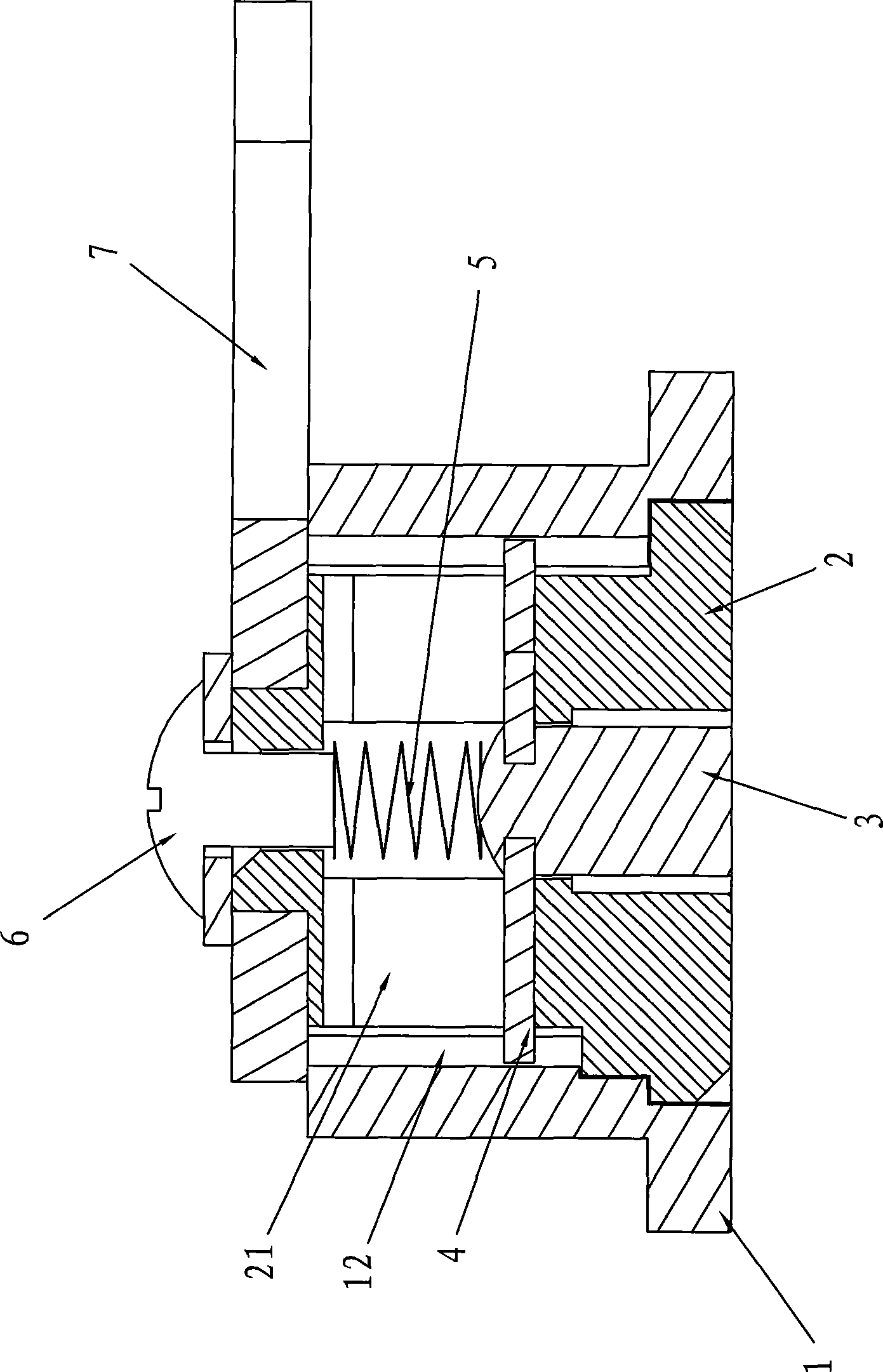

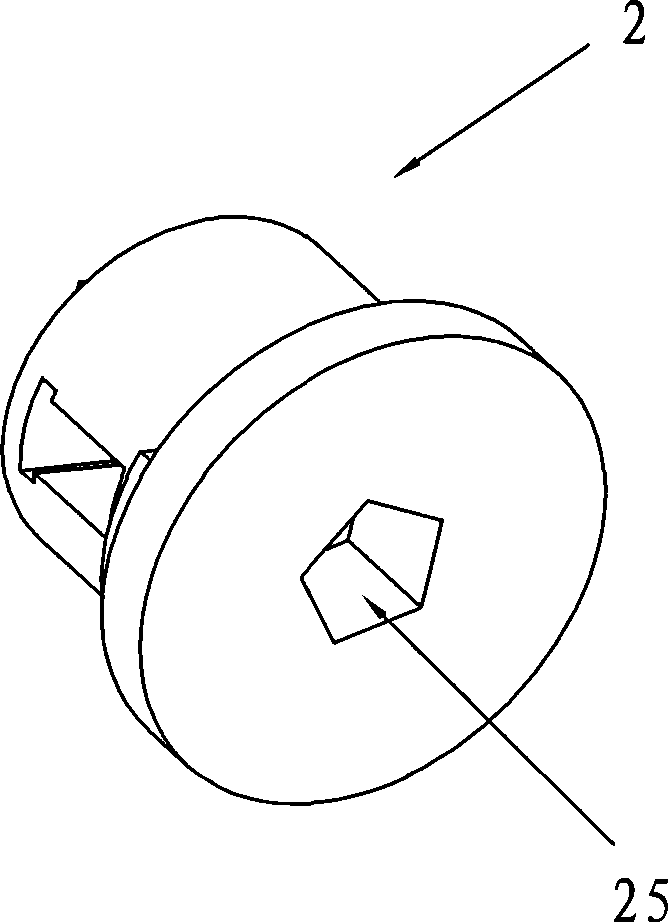

[0021] Such as figure 1 Shown, a kind of lockset comprises lock casing 1, lock core 2, jacking shaft 3, spring 5 and dead bolt 7, and lock core 2 is installed in the lock sleeve 1, and jacking shaft 3 is installed in the lock core 2; figure 2 , image 3 , Figure 4 As shown, there is a top shaft hole 24 on the lock core 2, a key hole 25 connected with the top shaft hole, an axial guide hole 21 penetrating in the radial direction is arranged on the lock core 2, and the key hole end of the lock core 2 has a guide Plate 22, the other end has deadbolt seat 23;

[0022] Such as Figure 5 , Figure 6 As shown, there is a guide platform 11 at the front end of the lock sleeve 1 that cooperates with the keyhole end of the lock cylinder, and a rotating cavity 13 for the sliding piece at the rear end of the lock sleeve. There can be two or four evenly distributed along the circle as required.

[0023] Also includes a sliding piece 4, one end of the top shaft 3 is fixedly connected...

Embodiment 2

[0026] As a further improvement, such as figure 2 , image 3 , Figure 4 As shown, there is a guide stop block 221 on the guide plate 22 of the lock cylinder 2; Figure 7 As shown, the guide platform 11 has a guide limit groove 111 , and the guide stop block 221 cooperates with the guide limit groove 111 . The guide limit groove 11 is a 90-degree arc. Top shaft can rotate 90 degree angles with lock core 2 like this. The guide limit groove can also be a 180-degree arc.

[0027] When the present embodiment is in use, the lock cylinder 2 rotates 90 degrees. or 180 degrees.

Embodiment 3

[0029] As a further improvement, such as Figure 8 As shown, there are two rotating grooves 14 of the sliding piece 4 on the inner wall of the rotating chamber 13 at the rear end of the lock sleeve 1, and the rotating grooves 14 are arranged symmetrically on a diameter line; The rotating cavity 13 between the 131 constitutes a rotating groove 14; the sliding plate 4 rotates in the rotating groove 14 at an angle of 90 degrees. The rotating groove 14 plays the role of limiting and stopping the sliding plate 4 . The guide limit groove 11 is a 90-degree arc.

[0030] When the present embodiment is in use, the lock core 2 rotates 90 degrees, and the sliding plate 4 rotates 90 degrees in the rotating groove 14 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com