Three-joist trussed steel beam linear control method

A technology of linear control and steel truss girders, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., and can solve problems that cannot well meet the construction requirements of three-truss steel truss girders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

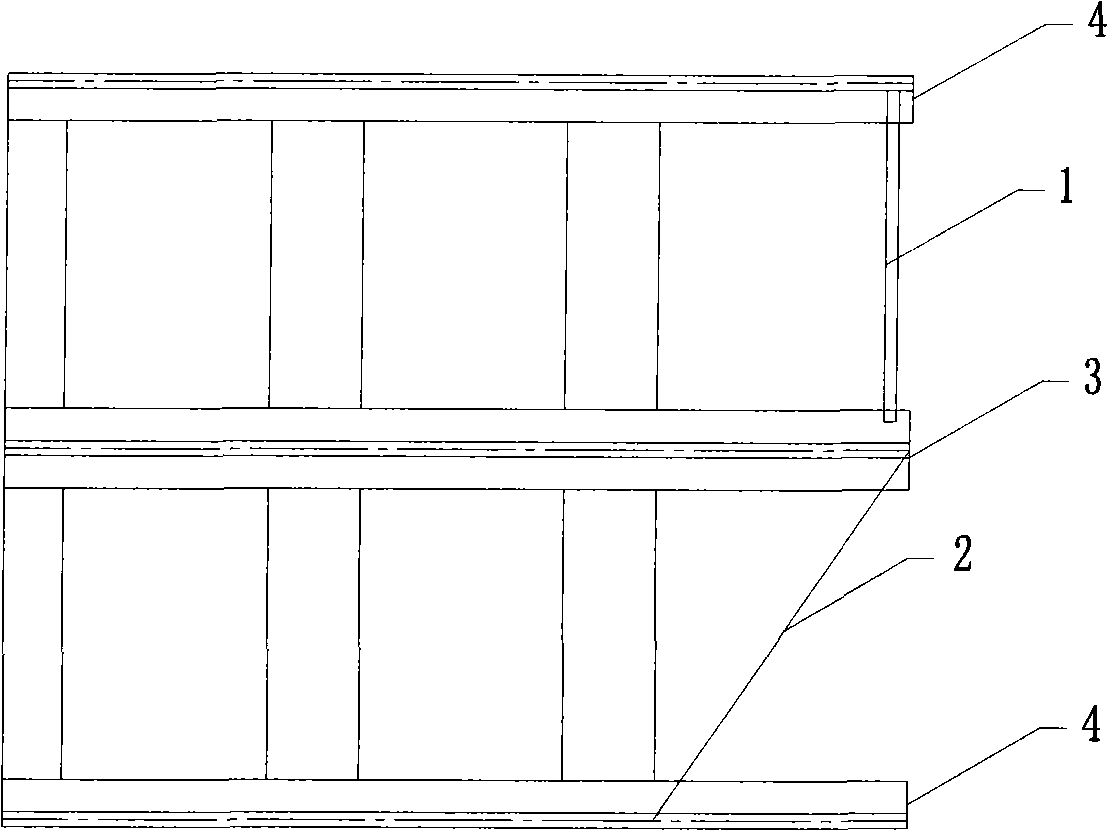

[0019] The invention provides a method for controlling the alignment of a three-truss steel truss girder, including elevation control and plane alignment control, such as figure 1 As shown, the elevation control includes the following steps:

[0020] A1: When assembling the main truss members between two adjacent steel truss girders, punch nails and high-strength bolts with 35% of the total number of holes in the upper foot evenly distributed according to 50% of the total number of holes, and loosen the hook after general tightening; Punching nails with 30% of the total number of holes and high-strength bolts with 30% of the total number of holes are punched into other rods, and the hooks are loosened. The diameter of the punching nails is 0.3-0.5mm smaller than the theoretical hole diameter;

[0021] A2: During the erection process, the height difference caused by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com