Cavity structure of ECR plasma sputtering apparatus

A sputtering device and plasma technology, which are applied in sputtering coating, ion implantation coating, metal material coating process and other directions, can solve the problems of high cost, unfavorable equipment use and high energy consumption when disassembling the target material, etc. Low cost, satisfying large-scale industrial production, and simple cavity structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

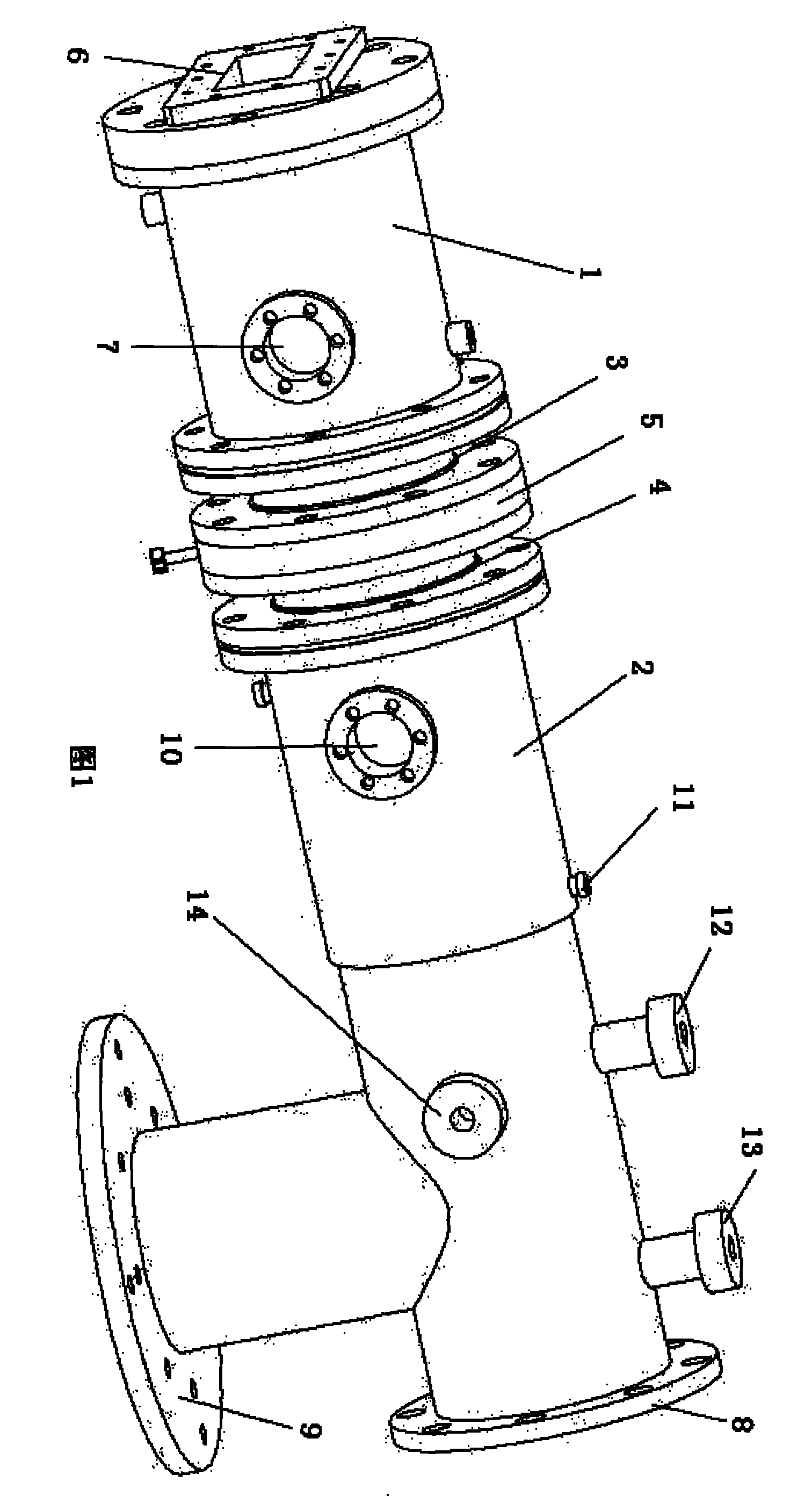

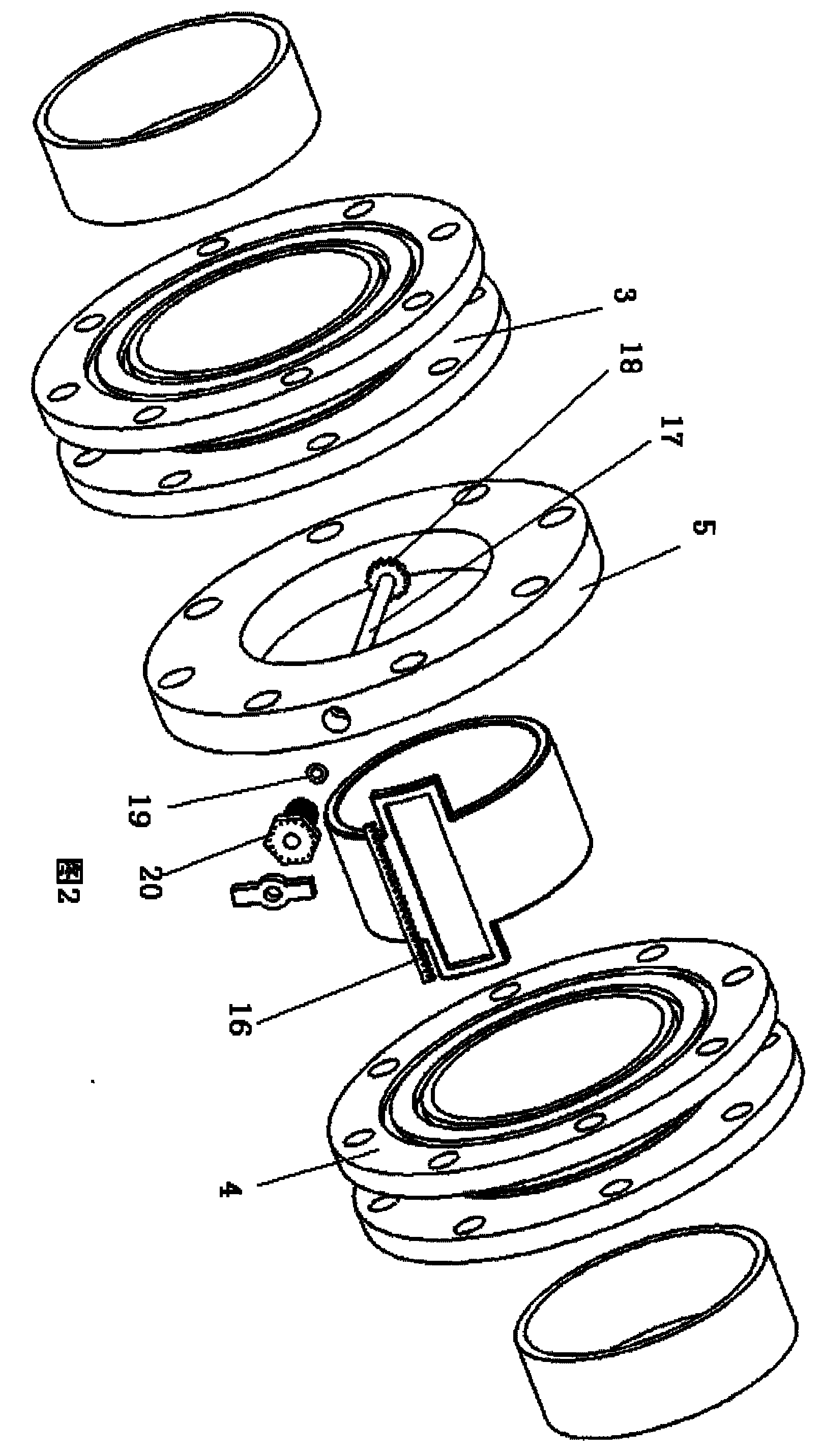

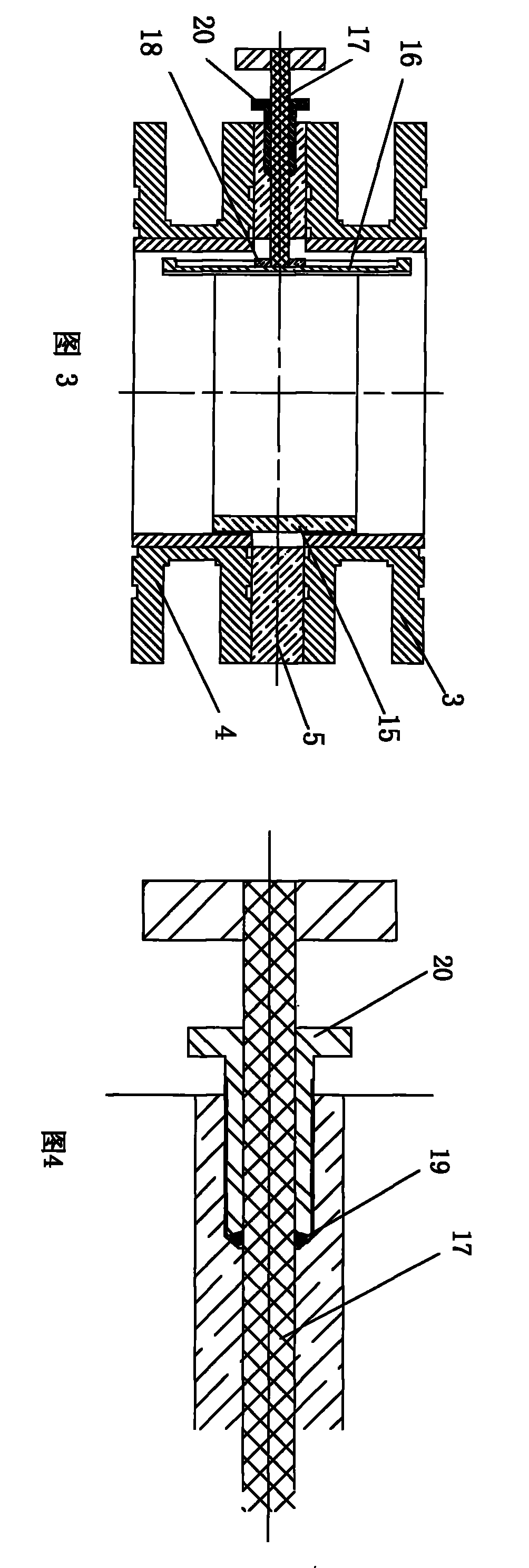

[0019] Referring to FIG. 1 , a particle source chamber structure of an ECR plasma sputtering device mainly includes: a left vacuum chamber 1 , a right vacuum chamber 2 and two target chambers, namely left and right target chambers 3 and 4 . The left vacuum chamber 1, the left target chamber 3, the right target chamber 4, and the right vacuum chamber 2 are sequentially connected by flanges, and a gasket 5 is arranged between the left and right target chambers 3 and 4, and the material of the gasket 5 is polyester Tetrafluoroethylene. Different targets are respectively placed in the left and right target cavities 3 and 4, and the targets are ring-shaped.

[0020] The entrance of the left vacuum chamber 1 is provided with a quartz window 6, and a first observation window 7 is arranged radially close to the left target chamber 1; the axial outlet of the right vacuum chamber 2 is provided with a retainer flange 8 connected to the substrate, radially The outlet is provided with a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com