Process for producing codoped In2O3 based pyroelectric material

A thermoelectric material, double-doping technology, applied in the field of material science, can solve the problems of high reaction temperature, long reaction time, large energy consumption, etc., and achieve the effect of overcoming high reaction temperature, improved sample performance, and low sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of preparation method of double-doped In2O3 based thermoelectric material provided by the present invention, its process steps are as follows:

[0026] 1) First press In 2-2x Zn x Ge x o 3 The stoichiometric ratio, weighed ZnO, GeO 2 and In 2 o 3 powder, where 0<x≤0.20;

[0027] 2) ZnO, GeO 2 and In 2 o 3 After the powders are mixed, they are calcined at 250° C. to 700° C. to complete the phase formation stage; the calcining time is preferably 1 to 6 hours.

[0028] 3) Put the calcined powder into a graphite mold, compact it, and sinter it into a bulk material with discharge plasma. ~10 minutes. That is, Zn, Ge double-doped In 2 o 3 Oxide thermoelectric materials.

Embodiment 1

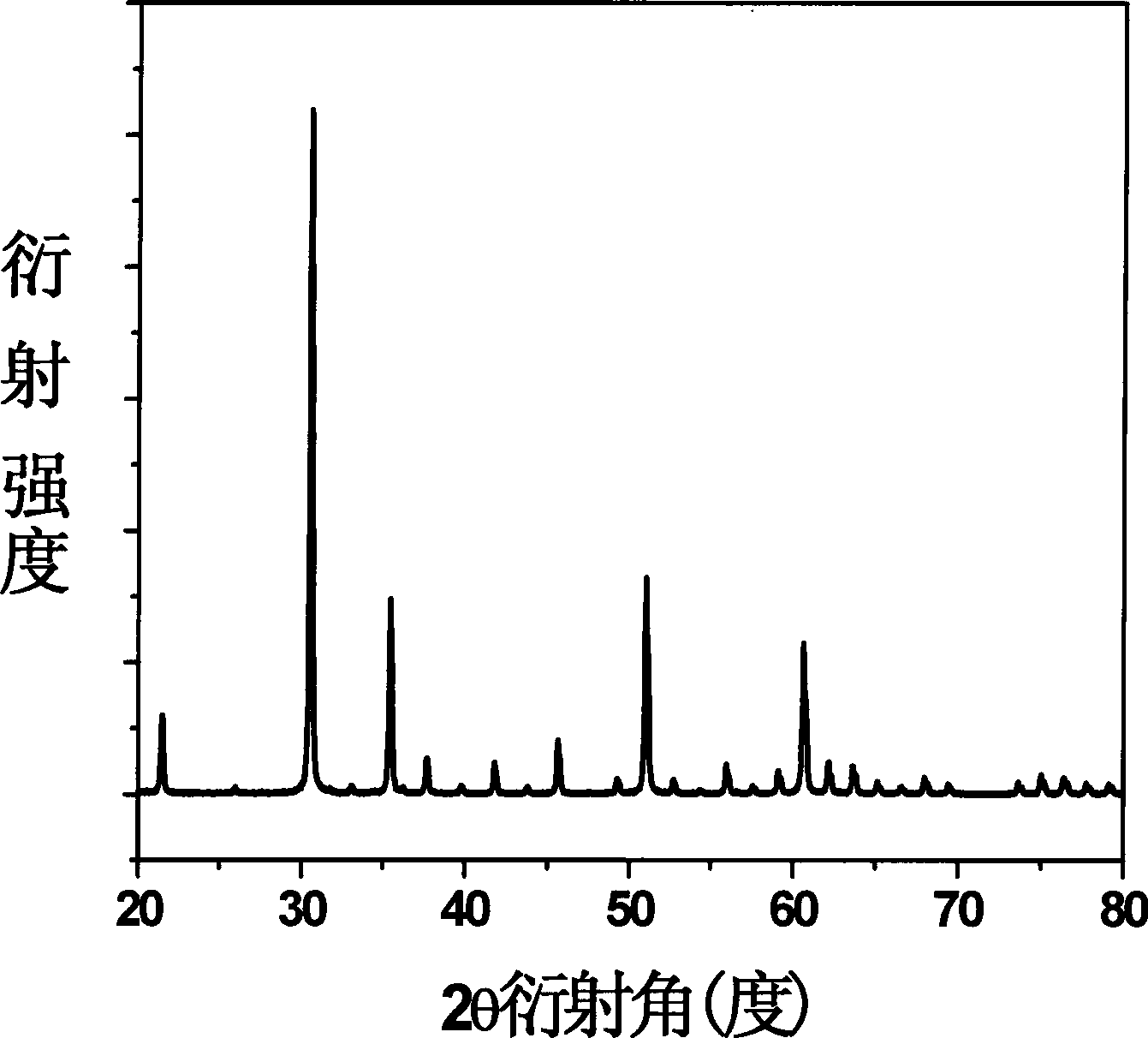

[0031] Follow In 1.98 Zn 0.01 Ge 0.01 o 3 The ratio, weigh ZnO, GeO 2 and In 2 o 3 , After mixing, through the pre-sintering process, sintering in the air at 250 ° C for 1 hour to complete the phase formation stage of the material phase. Then mix, granulate, and sinter in SPS discharge plasma sintering furnace under the condition of 850°C, the heating rate is 100°C / min, and keep warm for 2 minutes to obtain In 1.98 Zn 0.01 Ge 0.01 o 3 ceramics. its characteristics see figure 1 , 2 shows. Its ZT value can reach 0.4 at 700°C.

Embodiment 2

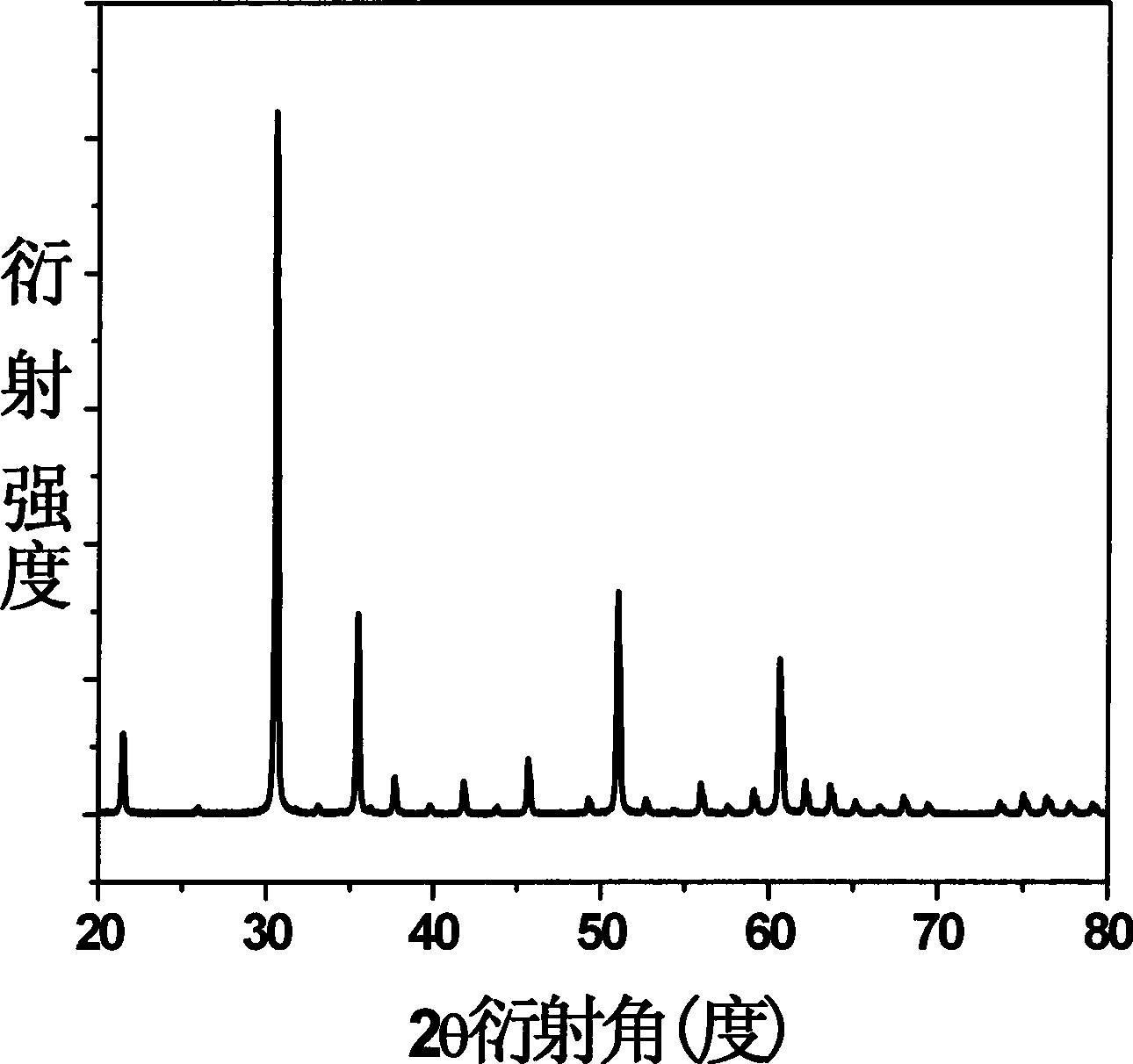

[0033] Follow In 1.90 Zn 0.05 Ge 0.05 o 3 The ratio, weigh ZnO, GeO 2 and In 2 o 3 , After mixing, through the pre-sintering process, sintering in air at 400 ° C for 3 hours to complete the phase formation stage of the material phase. Then mix, granulate, and sinter in SPS discharge plasma sintering furnace under the condition of 900°C, the heating rate is 130°C / min, and keep it for 4 minutes to obtain In 1.94 Zn 0.03 Ge 0.03 o 3 ceramics. its characteristics see image 3 , 4 shows. Its ZT value can reach 0.6 at 700°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com