Heating coil, induction heating equipment and manufacturing method for heating coil

A manufacturing method and technology for heating coils, which are used in coil manufacturing, induction heating, coil devices, etc., can solve the problems of large axial temperature difference of workpieces, slow heating efficiency of workpieces, limited axial distribution length, etc., so as to increase the number of coil turns, The effect of improving the heating efficiency and reducing the radial temperature difference inside the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

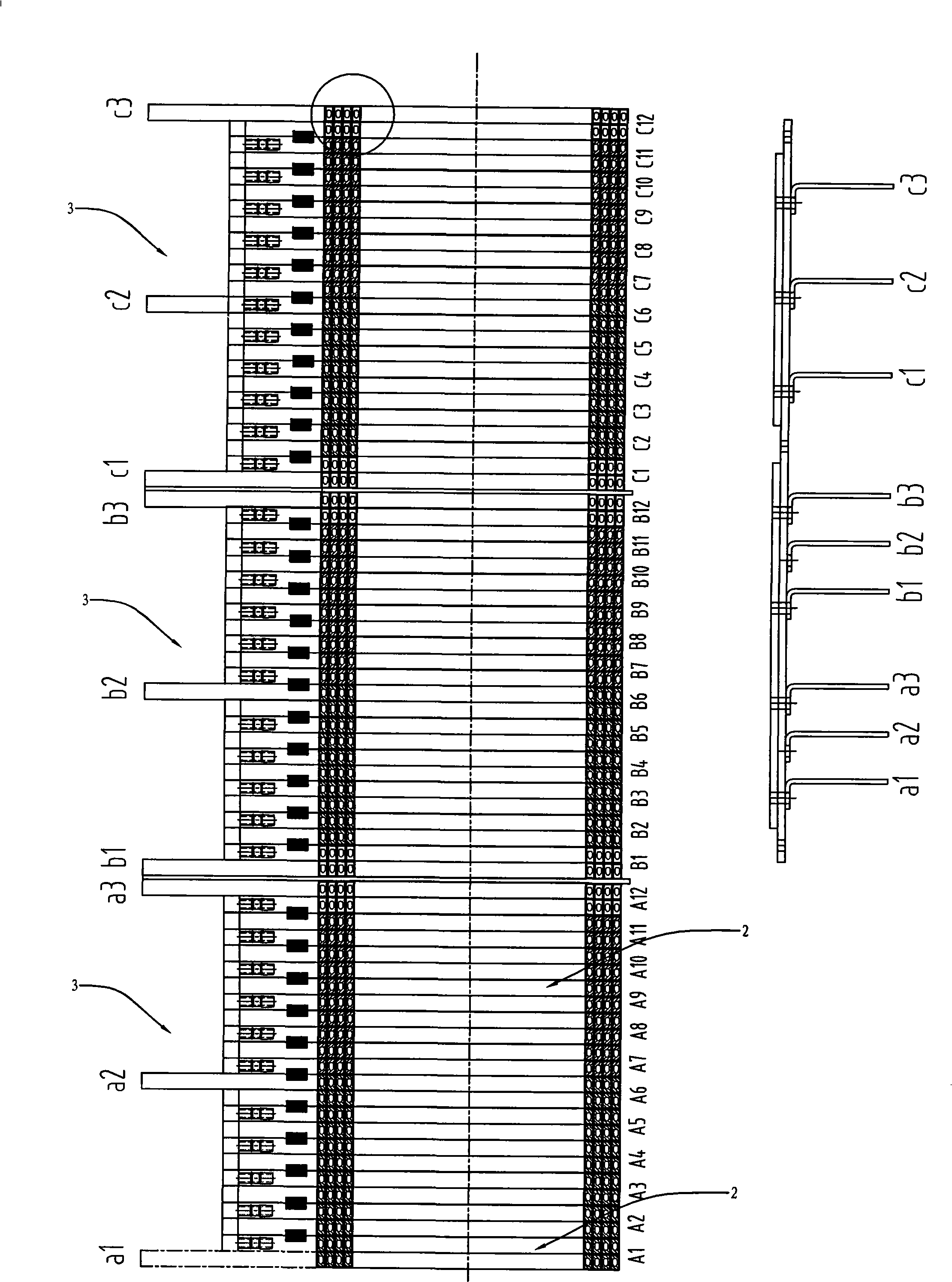

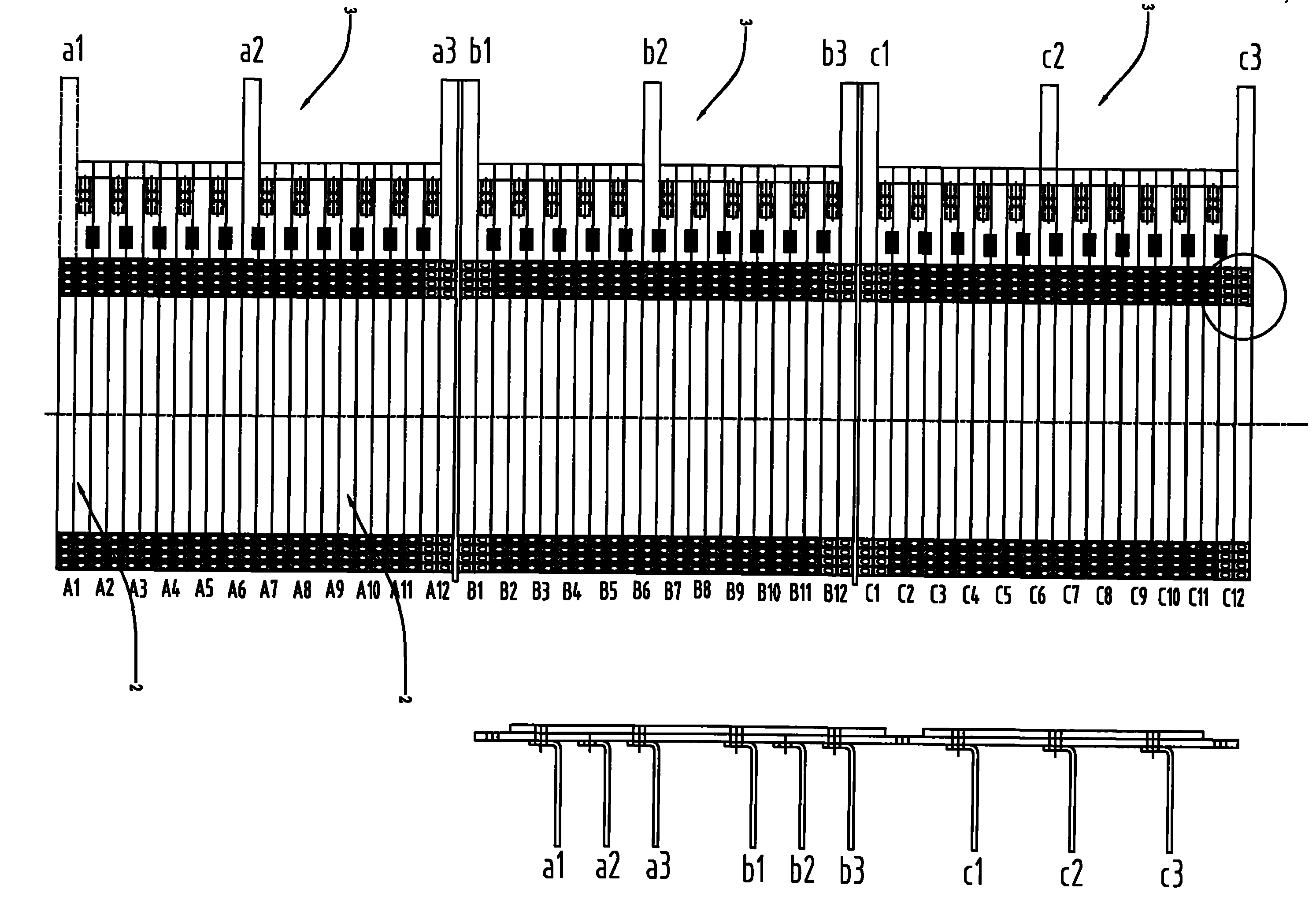

[0054] Such as figure 1 and figure 2 As shown, a heating coil includes a power cord 1 for connecting a transformer or a frequency converter; a coil 2 for generating magnetic flux, and the coil is similar to a circle; the heating coil includes a plurality of coils, and the plurality of coils 2 is at least two layers, and the multiple coils are at least two cakes. If the multiple continuous coils are distributed along a cylindrical surface, then the multiple coils are one layer; if the multiple continuous coils are distributed along multiple cylindrical surfaces, then the multiple coils are multiple layers. If the plurality of continuous coils are distributed in one plane, then the plurality of coils are a pie; if the plurality of continuous coils are distributed in multiple planes, then the plurality of coils are multi-cake.

[0055] The mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com