Screw rod drum-type filter press for continuous operation

A technology of filter press and screw barrel, which is applied in the field of filter press, can solve the problems of increasing investment cost of enterprises, pressing materials under high pressure, difficulty in adopting, etc., and achieves the goal of improving dehydration efficiency, good filter press effect, and improved filter press efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

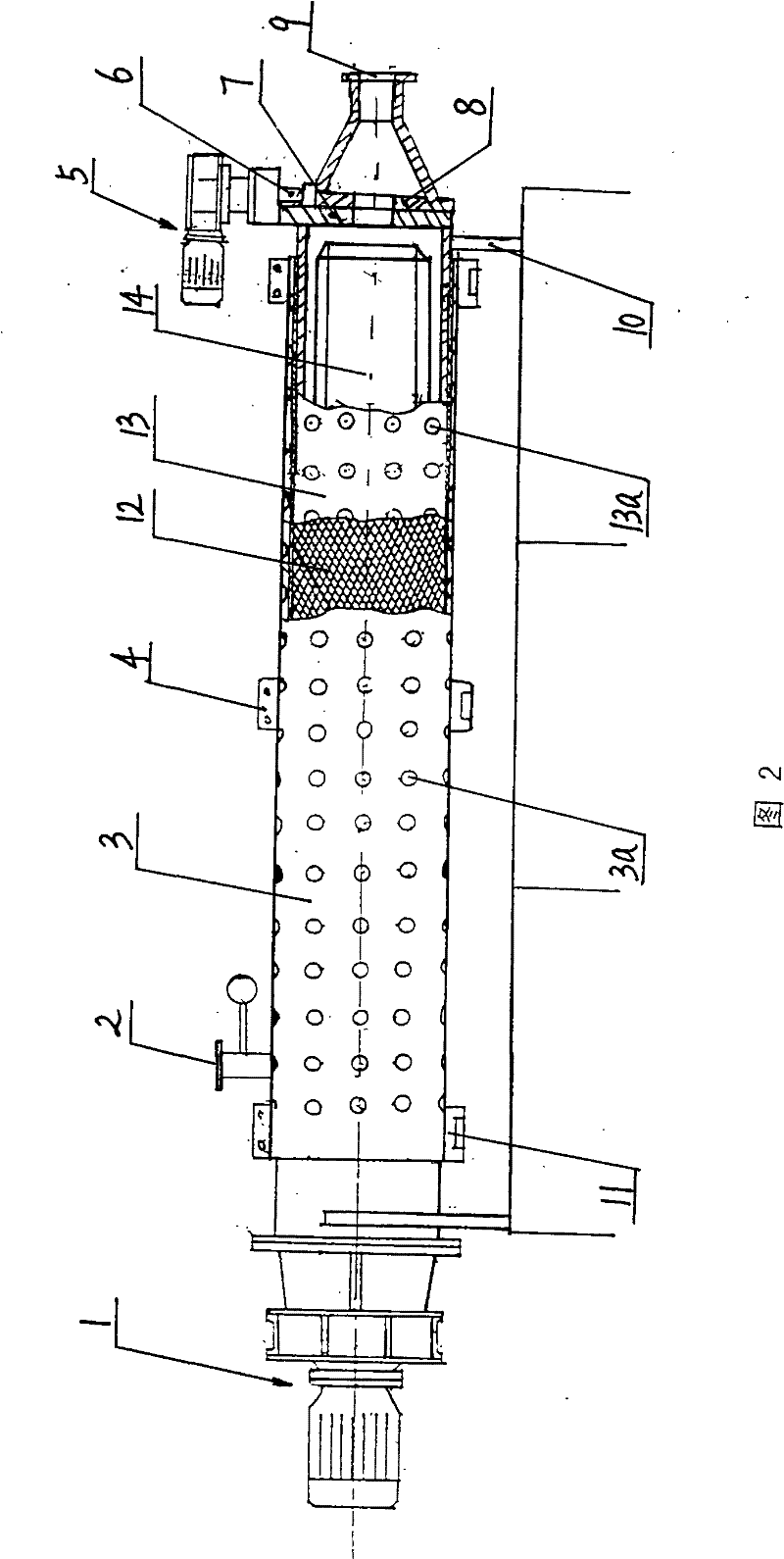

[0038] Figure 1 to Figure 7 The shown continuous-operating screw-drum filter press is one of the embodiments of the present invention, which includes a body, a support 10 for supporting the body, a screw 14, a screw driving device 1, a drainage mechanism, and The feed port 2 and the discharge port 9 at both ends of the body and the switch assembly at the discharge port, wherein the body adopts a horizontal cylinder, the screw 14 is located at the central axis of the cylinder, and its outer diameter is the same as The inner diameter of the barrel matches, that is, the outer diameter of the screw 14 is slightly smaller than the inner diameter of the barrel; the screw 14 is connected to the driving device 1, and the driving device 1 drives the screw 14 to rotate, conveying and dehydrating the material in the barrel, and pressing The water that comes out is discharged out of the cylinder through the drainage mechanism; the feed port 2 is used to connect with the pump material sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com