Mold for modifying waist of trousers

A mold and waistband technology, applied in the field of waistband hooking molds, can solve the problems of huge share and many customer demands, and achieve the effect of smooth and natural waist folding, low failure rate and accurate seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

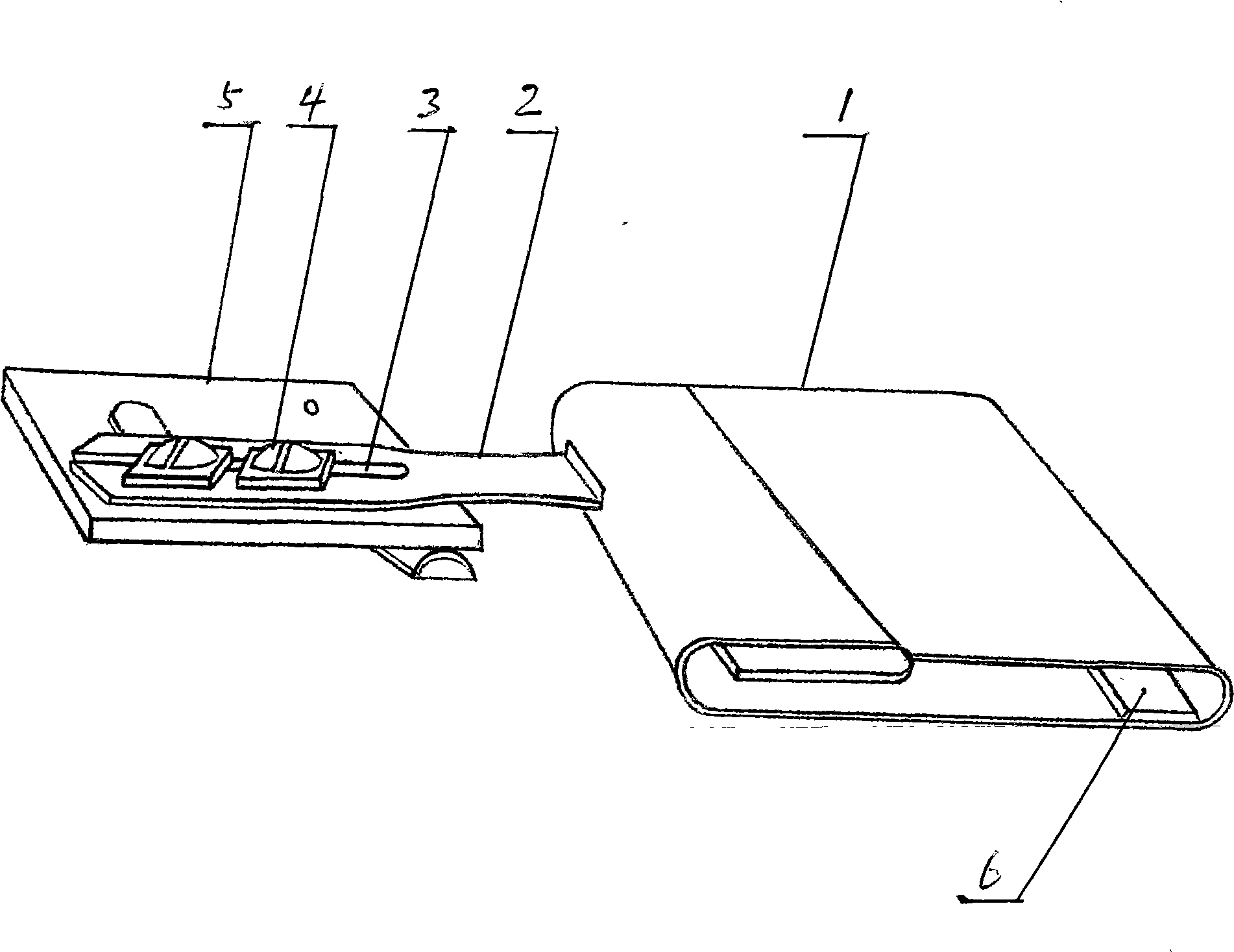

[0012] Such as figure 1 As shown, the jig 1 of the trouser waist mold is in the shape of an "e" shell, and is welded together with the base frame 2. The base frame 2 is provided with a fixed slot 3, and the screw 4 on the fixed slot 3 and the needle The threaded fit of the plate 5 connects the pedestal 2 and the jig 1 with the needle plate 5 in a suitable position. A fixed block 6 is arranged on one side of the "e"-shaped shell-shaped fixture 1 . During making, can determine the concrete size specification of jig 1 by the requirement of sewing (seam allowance, width in the waist).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com