Mobile cloth-jointing sewing machine

A sewing machine, mobile technology, applied in sewing machine components, cloth feeding mechanisms, sewing equipment, etc., can solve the problems of inconvenient movement of cloth, and achieve the effect of improving cloth utilization, improving labor production efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

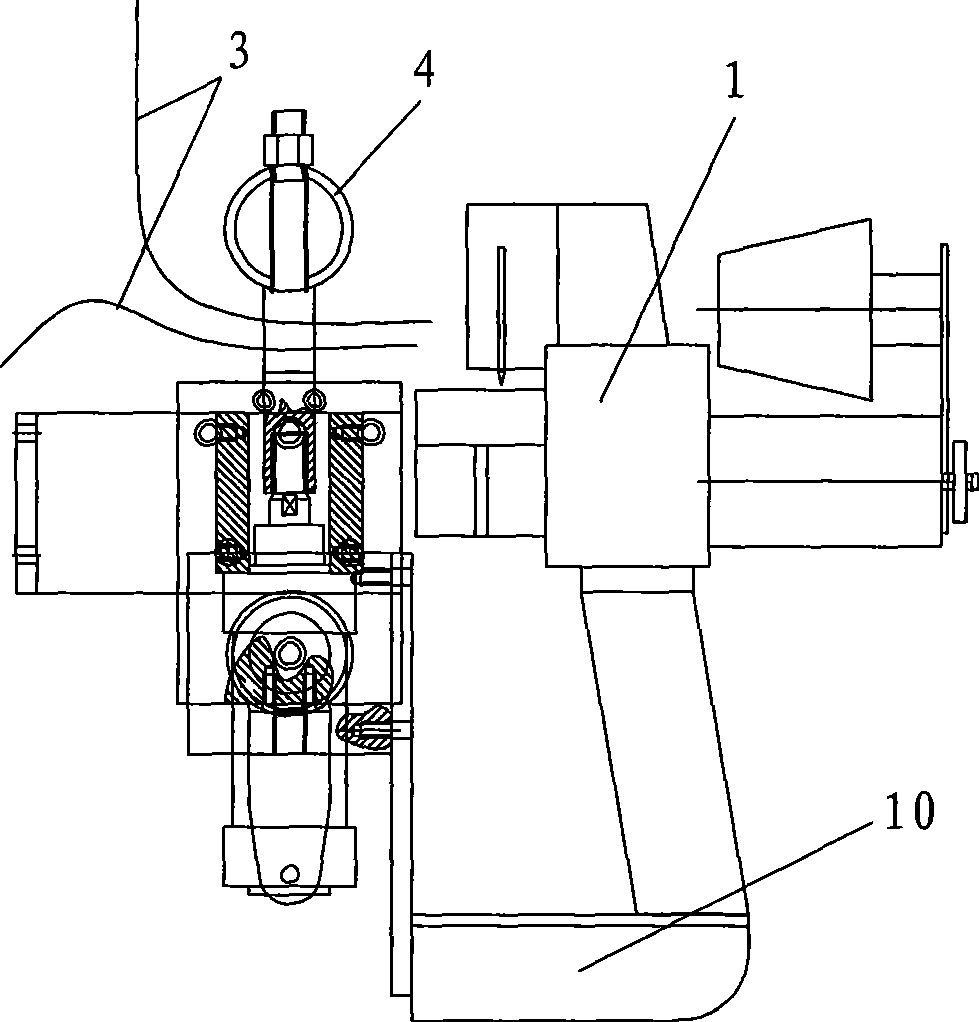

[0018] see figure 1 , along the width direction of the cloth being connected on the production line, a cloth clamp composed of a pressure rod 7 and an upper pressure rod 4 is arranged in parallel, and the pressure rod 7 and the upper pressure rod 4 can be displaced relative to each other along the radial direction to form two Two position states, one is that the upper pressure rod 4 is pressed against the pressure bearing rod 7 to form a clamping state, and the other is that the upper pressure rod 4 is separated from the pressure bearing rod 7 and is in an unclamped state;

[0019] A linear track 8 parallel to the pressure rod 7 is set, and a movable block 9 that can slide along the linear track 8 is arranged on the linear track 8; the sewing machine head 1 facing the cloth clamp is fixed on the movable block through a cantilevered machine base 10 9 on.

[0020] In specific implementation, the corresponding structural settings also include:

[0021] Pressure bearing bar 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com