Protective helmet shell dismounting structure with rear view function

A safety helmet and shell technology is applied in the field of disassembly and assembly structure of the safety helmet shell, which can solve the problems of affecting safety, troublesome disassembly and assembly of the safety helmet shell, damage to the surface paint and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

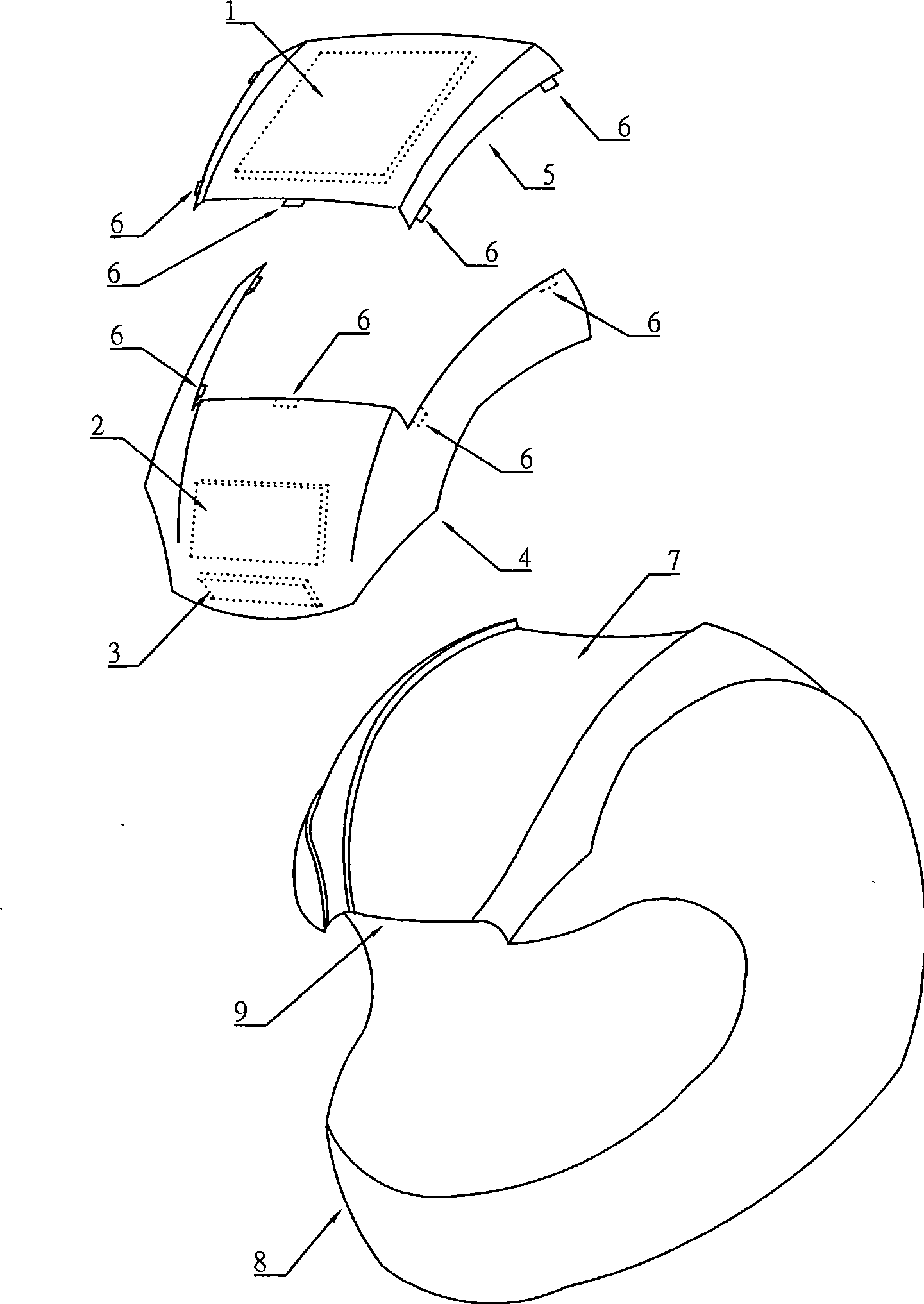

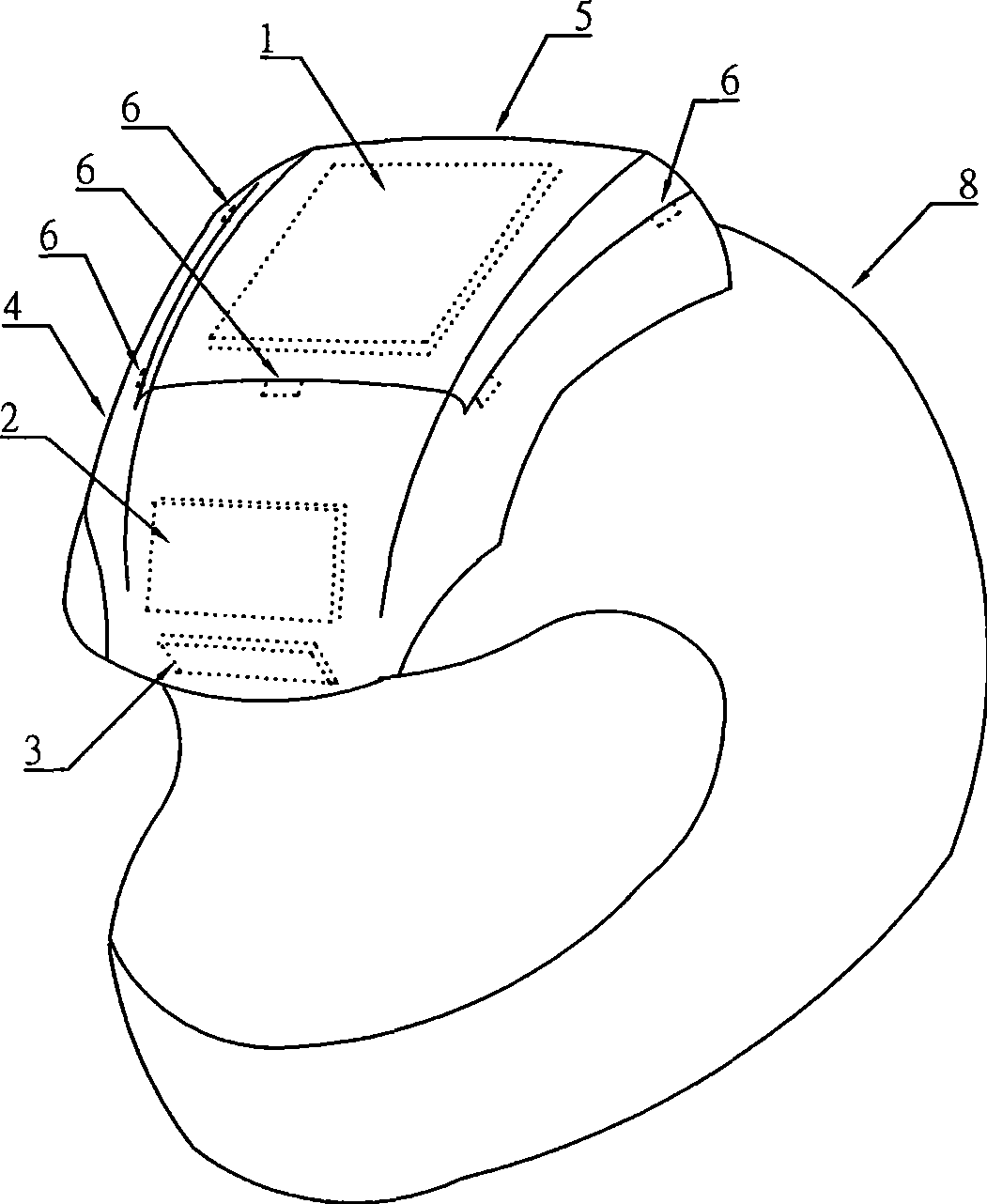

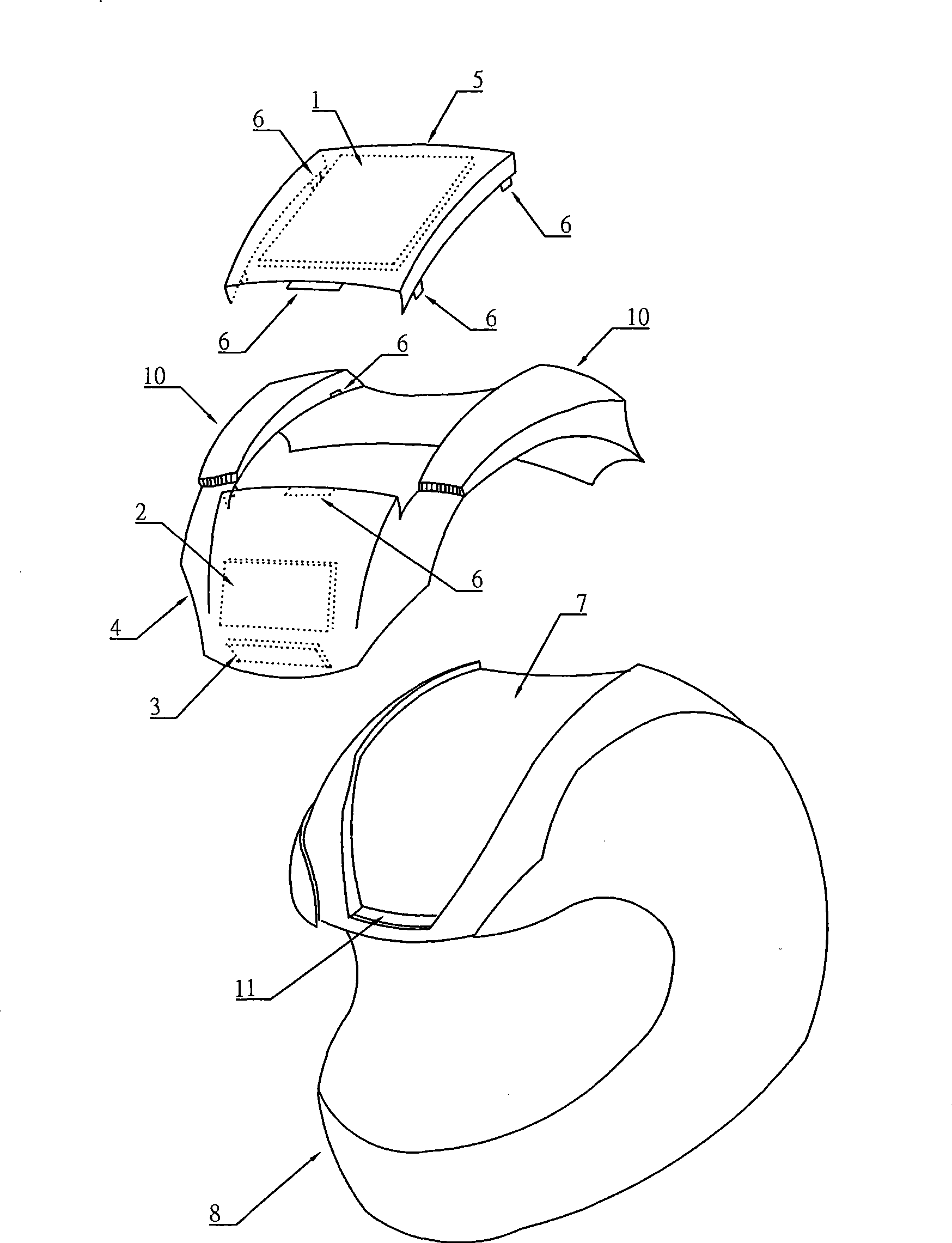

[0018] The helmet shell dismounting structure with rear view function of the present invention, such as figure 1 , figure 2 As shown, the structure includes:

[0019] A shell 4, which is divided to form at least one secondary shell 5;

[0020] At least two mirrors (the first mirror 1, the second mirror 2, and the third mirror 3) are respectively arranged on the housing and the sub-housing, and the mirrors reflect each other so that they can reflect the rear image forward and transmit it to the user. the eyes;

[0021] At least one disassembly object 6 (screws, holes, nails, glue, buckles, claws, grooves, protruding rails, pins, etc.) is arranged between the shell and the auxiliary shell, so that The auxiliary shell can be disassembled on the shell;

[0022] In this way, the convenience of maintaining the reflector can be achieved by utilizing the detachable attachment of the sub-housing to the housing.

[0023] Wherein, the shell 4 can be connected (adhesive, screwed, cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com