Oil film coating method for friction assembly

A component and oil film technology, applied in the direction of pivot connection, etc., can solve the problems of oil pollution, missing, unable to produce quickly and in large quantities, and achieve the effect of avoiding contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Regarding the technology, means and effects used in the present invention, a preferred embodiment is given and described in detail below with drawings, which are for illustration purposes only, and are not limited by this structure in the patent application.

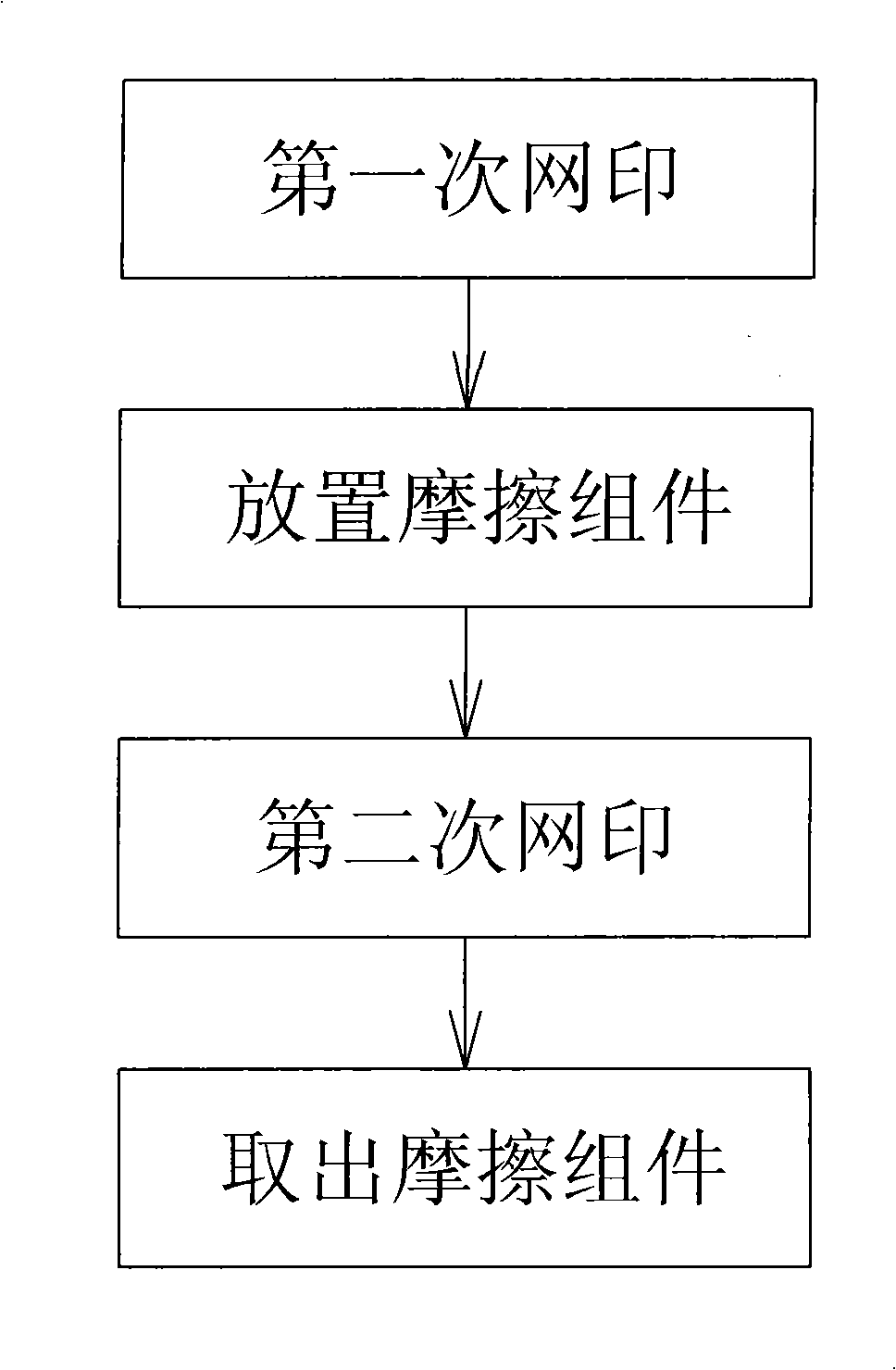

[0038] refer to figure 1 , is a flow chart of the method for coating the oil film on both sides of the friction component of the present invention. The production process of the oil film printing method of the friction component of the present invention is carried out according to the following steps, the first screen printing → placing the friction component → the second screen printing → taking out the friction component.

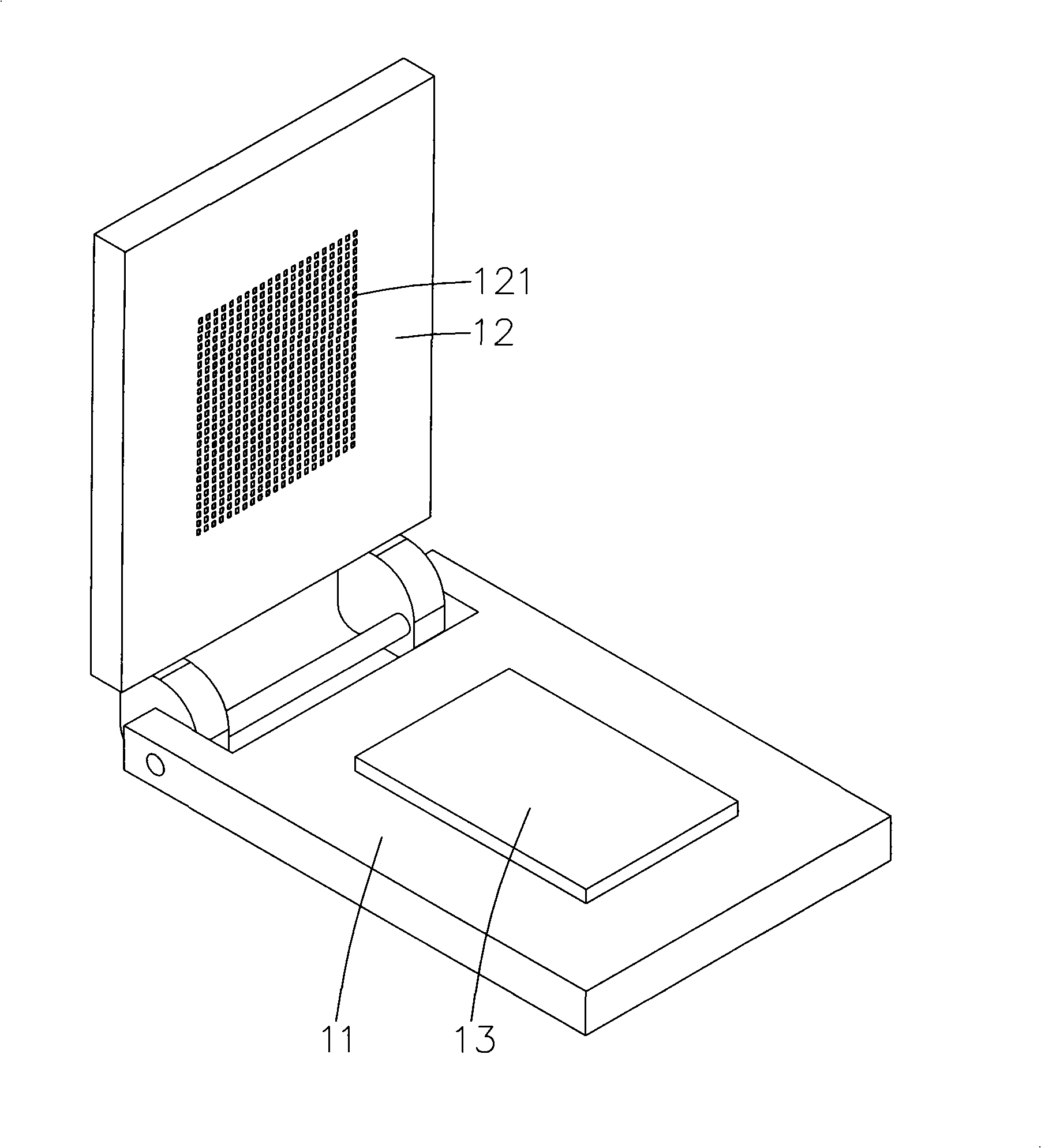

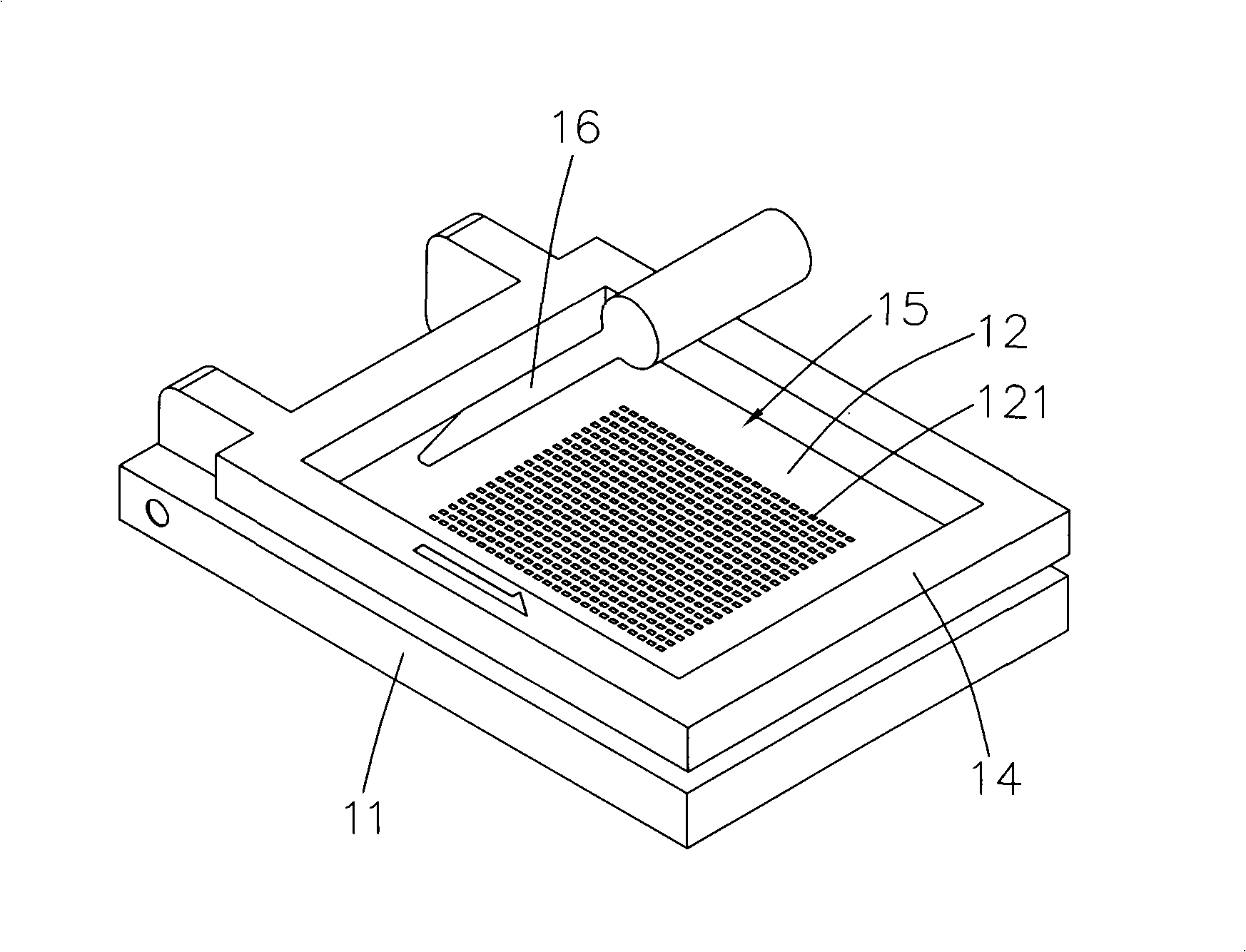

[0039] refer to Figure 2 to Figure 6 , is a schematic diagram of the method for coating the oil film on both sides of the friction component of the present invention. The oil film printing method of the friction assembly of the present invention is to prepare a base plate 11 and a screen p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com