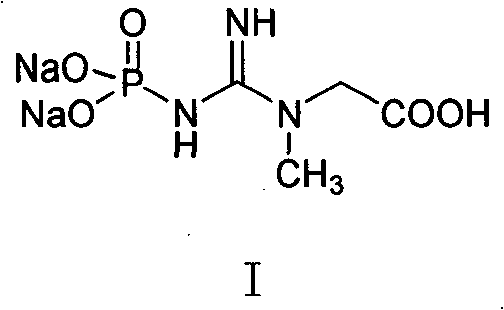

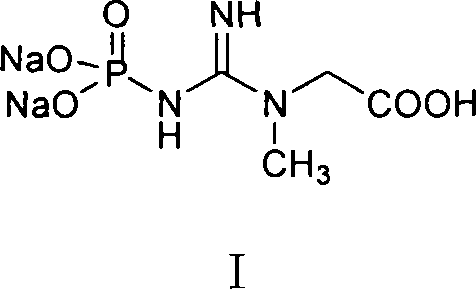

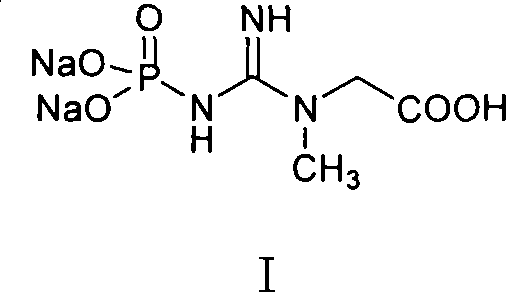

Synthesis of phosphocreatine disodium salt

A technology of creatine phosphate disodium salt and disodium creatine phosphate, which is applied in the field of high-energy compounds, can solve the problems of unrecoverable raw materials, high cost, and low yield, and achieve more product purification times, increased costs, and increased purification times Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of synthetic method of creatine phosphate disodium salt is:

[0022] The first step. dissolving disodium creatinine phosphate in 2 times the weight of water, decolorizing with 5% of the weight of activated carbon in an ice-water bath, filtering, adding 4 times the weight of ethanol to the filtrate, and suctioning to obtain disodium creatinine phosphate products;

[0023] The second step. Dissolve the refined product of disodium creatinine phosphate prepared in the first step in 2 times the weight of water, add 10% times the weight of activated carbon, stir in an ice-water bath for 1 hour, filter, and add hydrogen to the filtrate Adjust the pH of the solution to 13 with sodium oxide, stir at 80°C for 0.1 hour, then adjust the pH to 7 with hydrochloric acid in an ice-water bath, decolorize with 20% of the weight of activated carbon at room temperature, filter, add 6 times the weight of ethanol to the filtrate, and continue stirring at room temperature for 12 hours....

Embodiment 2

[0028] A kind of synthetic method of creatine phosphate disodium salt is:

[0029] The first step. dissolving disodium creatinine phosphate in 5 times the weight of water, decolorizing with 20% of the weight of activated carbon in an ice-water bath, filtering, adding 40 times the weight of ethanol to the filtrate, and suctioning to obtain disodium creatinine phosphate products;

[0030] The second step. Dissolve the refined product of disodium creatinine phosphate prepared in the first step in 6 times the weight of water, add 20% times the weight of activated carbon, stir in an ice-water bath for 1 hour, filter, and add hydrogen to the filtrate Adjust the pH of the solution to 13 with sodium oxide, stir at 50°C for 18 hours, then adjust the pH to 8.5 with hydrochloric acid in an ice-water bath, decolorize with 10% of the weight of activated carbon at room temperature, filter, add 46 times the weight of ethanol to the filtrate, and continue stirring at room temperature for 12 ...

Embodiment 3

[0035] A kind of synthetic method of creatine phosphate disodium salt is:

[0036] The first step. dissolving disodium creatinine phosphate in 8 times the weight of water, decolorizing with 10% of the weight of active carbon in an ice-water bath, filtering, adding 80 times the weight of ethanol to the filtrate, and suctioning to obtain disodium creatinine phosphate products;

[0037] The second step. Dissolve the refined product of disodium creatinine phosphate obtained in the first step in 10 times the weight of water, add 5% times the weight of activated carbon, stir in an ice-water bath for 1 hour, filter, and add hydrogen to the filtrate Adjust the pH of the solution to 14 with sodium oxide, stir at 20°C for 36 hours, then adjust the pH to 10 with hydrochloric acid in an ice-water bath, decolorize with 5% of the weight of activated carbon at room temperature, filter, add 100 times the weight of ethanol to the filtrate, and continue stirring at room temperature for 12 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com