Diameter adjustable water-mill oxygen increasing machine impeller

A waterwheel aerator and impeller technology, applied in water aeration, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problems of inability to adjust the diameter, trouble, etc., and achieve low cost and convenient locking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

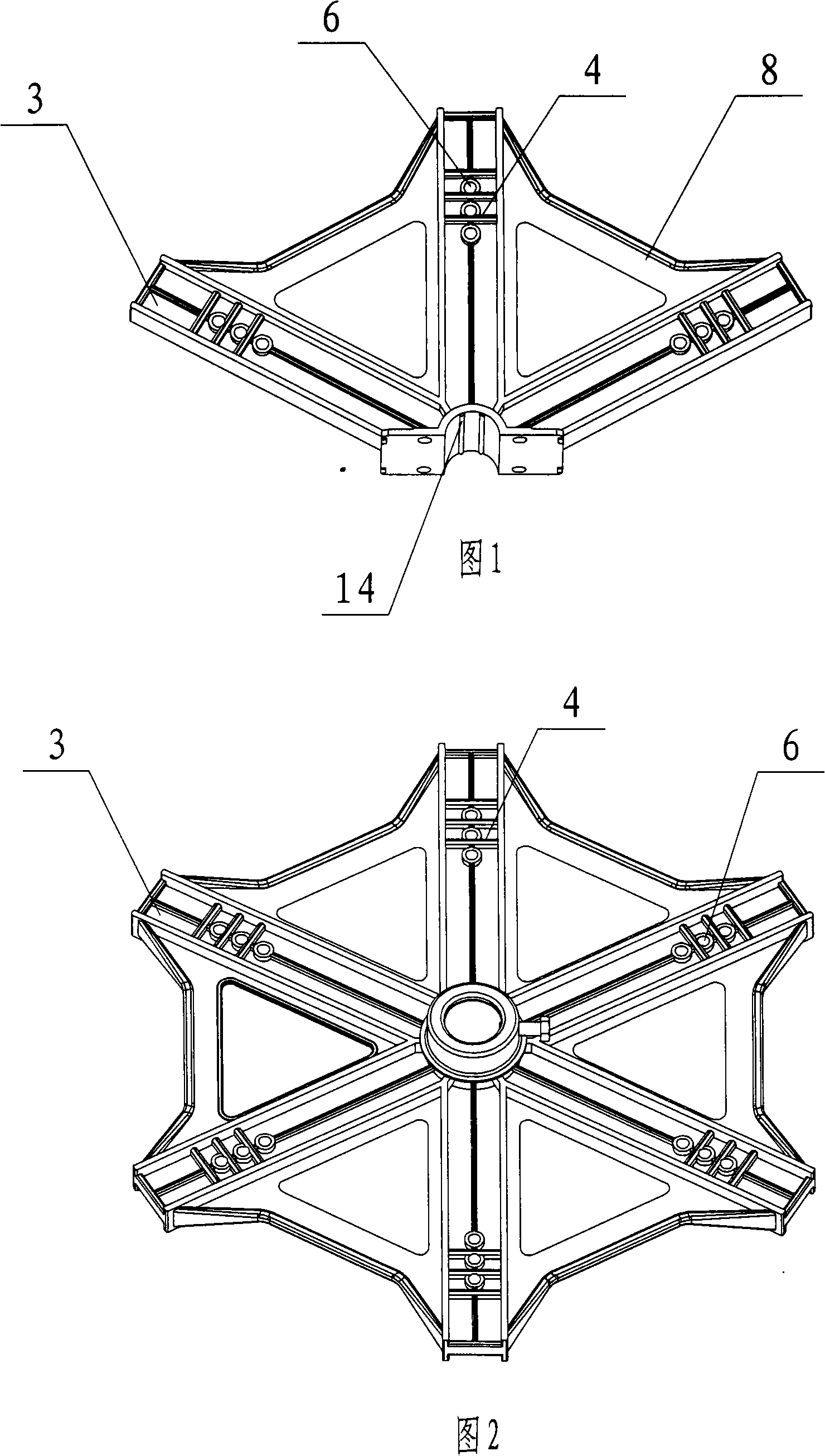

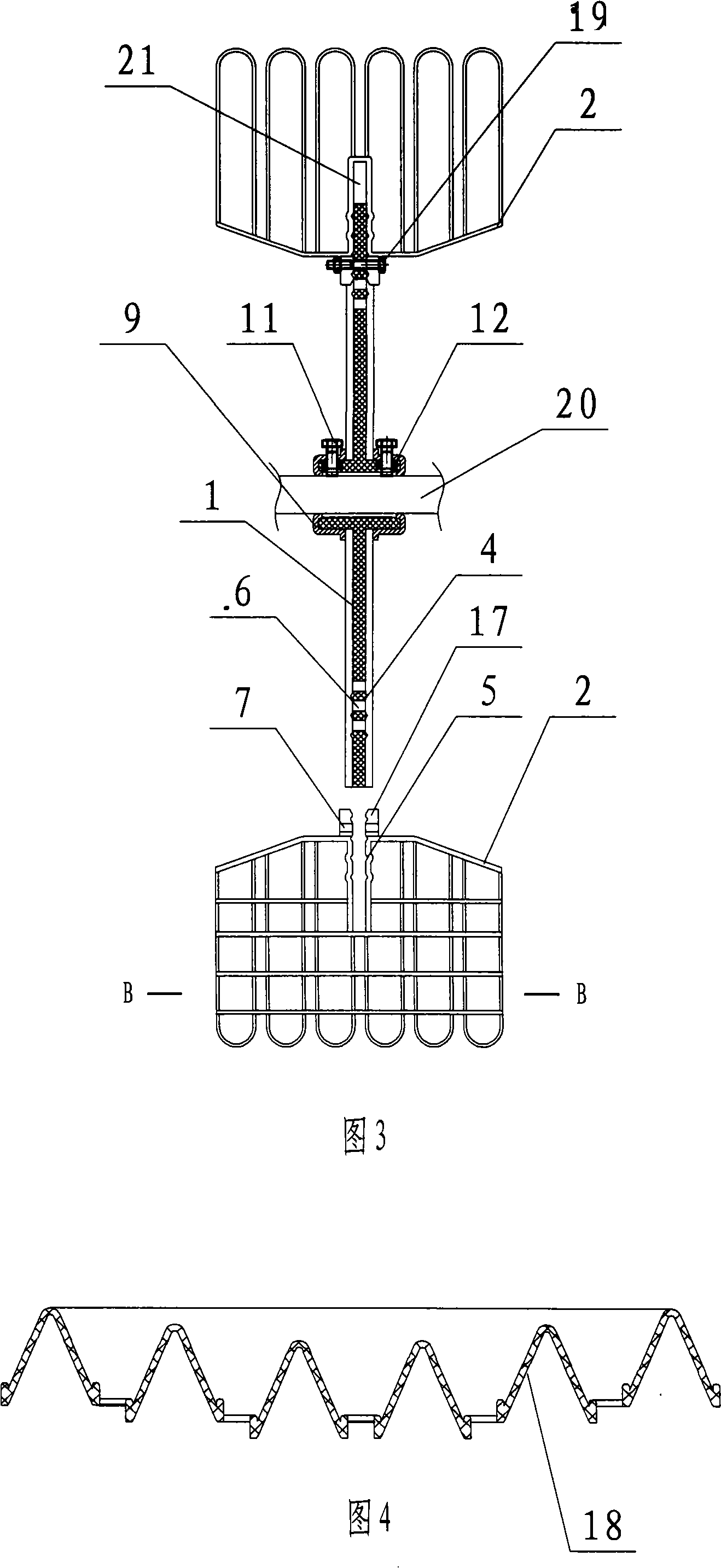

[0025] Embodiment 1, as shown in Figures 1, 2, and 3, a plurality of fixing holes (6) are formed in the fixed frame (3), and opening grooves (21) and connecting through holes (7) are formed on the blade handle (17) , the opening slot (21) of the blade shank (17) is plugged and connected with the fixing bracket (3) of the wheel disc (1), and is fixed by the bolt (19) passing through the fixing hole (6) and the connecting through hole (7) , in order to improve the connection reliability and positioning effect, a plurality of convex ribs (4) are formed on the fixed frame (3) of the wheel disc (1), and a plurality of convex ribs (4) are formed in the opening groove (21) of the blade handle (17). Groove (5), protruding rib (4) and groove (5) positioning fit, this kind of matching method is more reliable, suitable for blades with larger area, choose different fixing holes (6) and connecting through holes (7) to match , the purpose of adjusting the impeller diameter can be achieved. ...

Embodiment 2

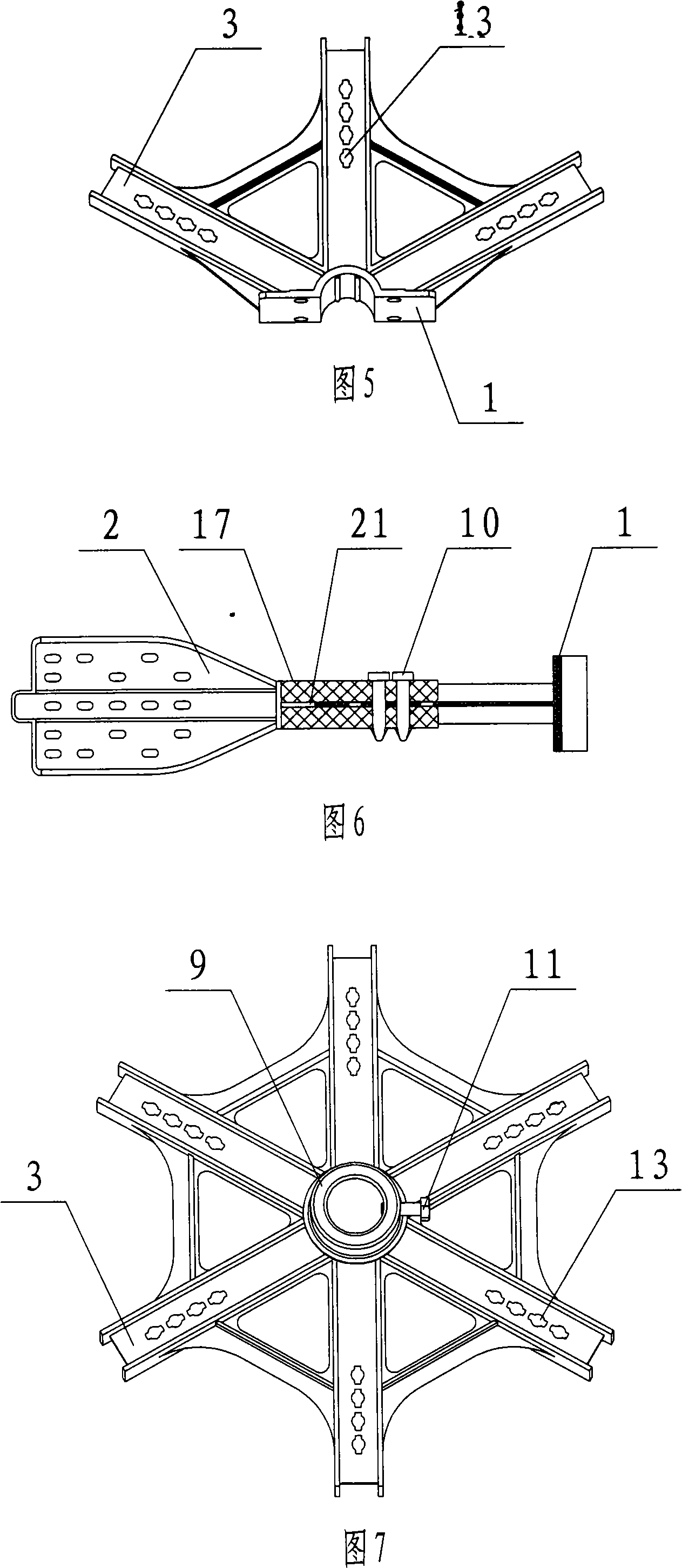

[0026] Embodiment two, as shown in Figure 5,6,7,8,9, be shaped on a plurality of fixing holes (13) with long slots in the fixed frame (3), be shaped on opening groove (21) at blade shank (17) ) and a plurality of connecting through holes (23) with long grooves, the opening groove (21) of the blade shank (17) is connected to the fixed frame (3) of the wheel (1), and is connected by the locking bolt (10) Pass through the fixing hole (13) with the long groove and the connection through hole (23) with the long groove to be fixed, in order to improve the connection reliability, multiple lock pins (10) can be used, and one end of the lock pin (10) is a round There is a protruding lock button (16) in the diameter direction, and the other end is square or hexagonal. There is a positioning platform (15) under the shoulder rest, and the locking bolt (10) passes through the fixing hole (13) with a long slot. ) and the connecting through hole (23) with a long groove, rotate 90 degrees, th...

Embodiment 3

[0027] Embodiment three, such as Figure 11 , 12 As shown, the fixing frame is formed with a fixing groove (22), and the opening groove (21) of the blade shank (17) is plugged and connected with the fixing frame (3) of the wheel disc (1), and is passed through and fixed by a bolt (19). The groove (22) is fixed to the connection through hole (7). This connection method can make the diameter of the impeller steplessly adjusted, but the connection reliability is not as good as that of the first embodiment.

[0028] The impeller of the present invention and drive shaft fixing method have multiple, as one: wheel disc (1) is made up of two half wheel discs, half wheel disc and half wheel disc combination are fastened on the drive shaft by bolt (19), and half wheel disc and half wheel disc combination are fastened on the drive shaft by bolt (19). The roulette structure is for the convenience of disassembly and assembly of the roulette (1) and the transmission shaft (20), in order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com